A binary plug nozzle

A plug-type nozzle and nozzle technology, which is applied to jet propulsion devices, machines/engines, etc., can solve the problems of increased nozzle stern angle and reduced thrust performance, achieve efficient throat area adjustment, and meet different working conditions. the desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same elements unless otherwise indicated.

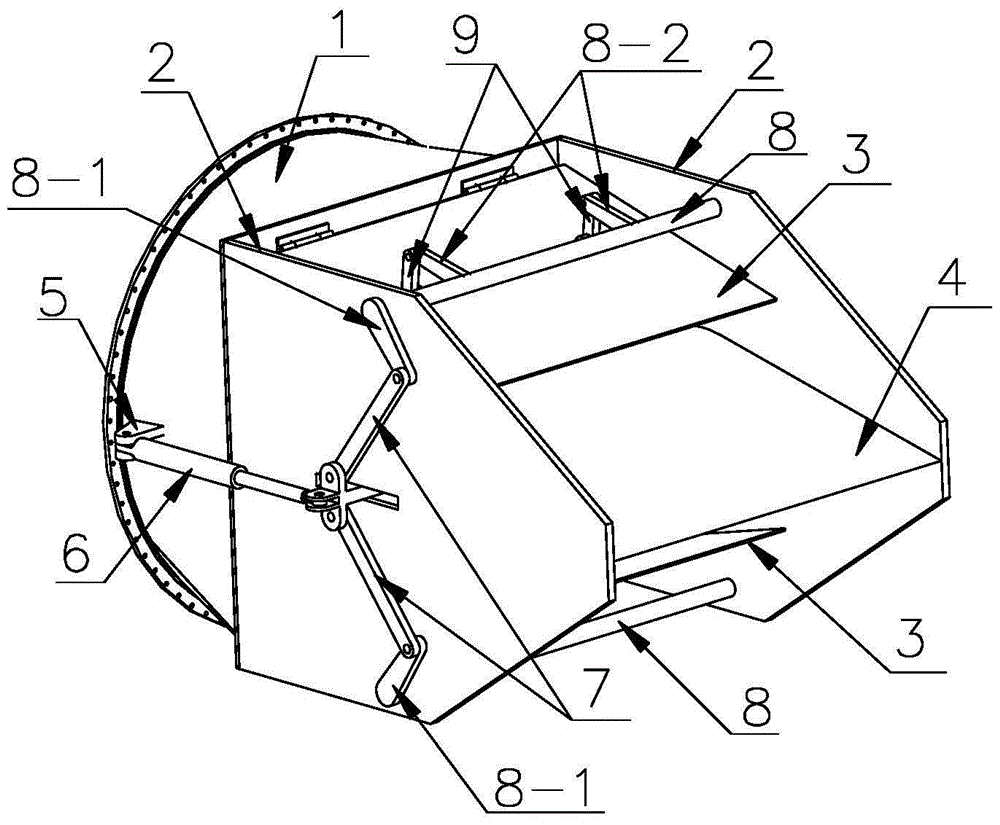

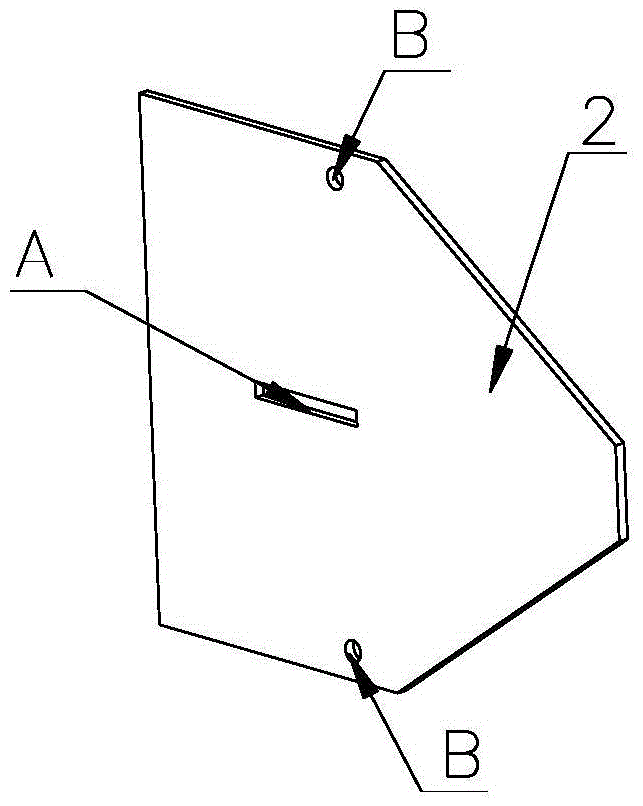

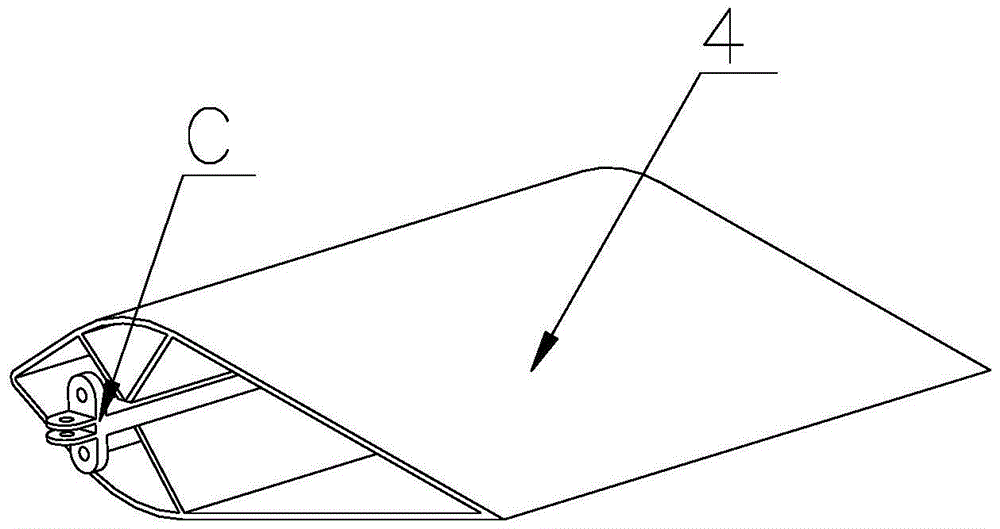

[0016] Such as figure 1 and figure 2 As shown, a binary plug nozzle provided by the present invention includes a cylinder body 1, a side wall 2, a converging section 3, a plug cone 4, a mounting seat 5, an actuator cylinder 6, a pull rod 7, a rocker arm 8 and The connecting rod 9 is characterized in that: the number of the cylinder 1 is 1, the inlet is circular, the outlet is square, and the middle is evenly transitioned; the side wall 2 and the cylinder 1 are fastened and connected by bolts, and the number is 2. Arranged symmetrically on the left and right sides of the nozzle, there is one chute A and two round holes B on it, the horizontal center plane of the chute A coincid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com