Metal pipe wall mesh gradient servo ring punching equipment

A metal tube and mesh technology, which is applied in the field of metal pipe wall mesh gradient servo ring punching equipment, can solve the problems of not being able to punch through holes of different shapes, achieve strong arbitrariness, accurate graduation, and solve the problem of waste output. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

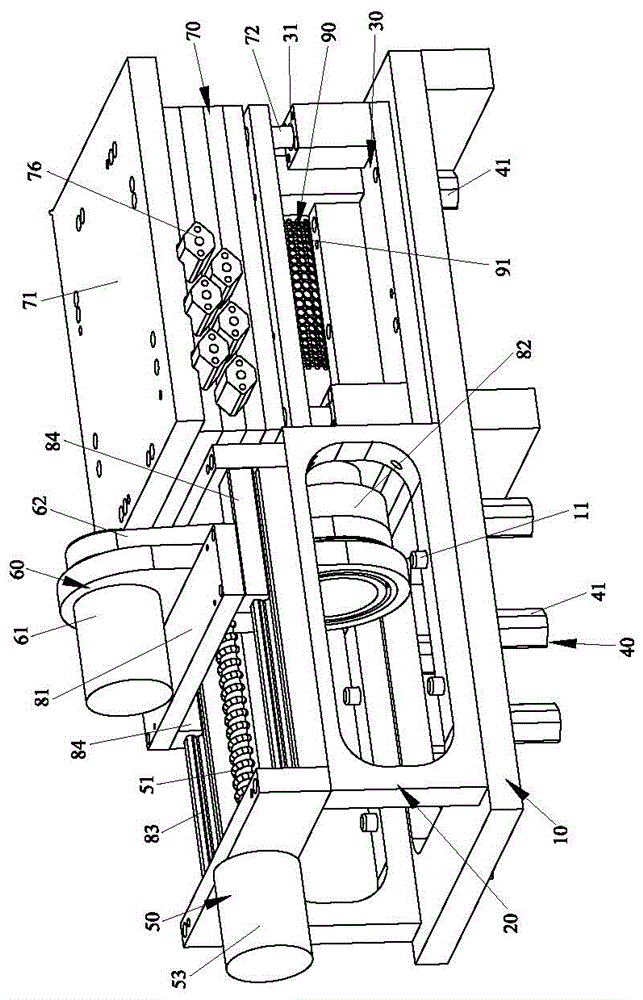

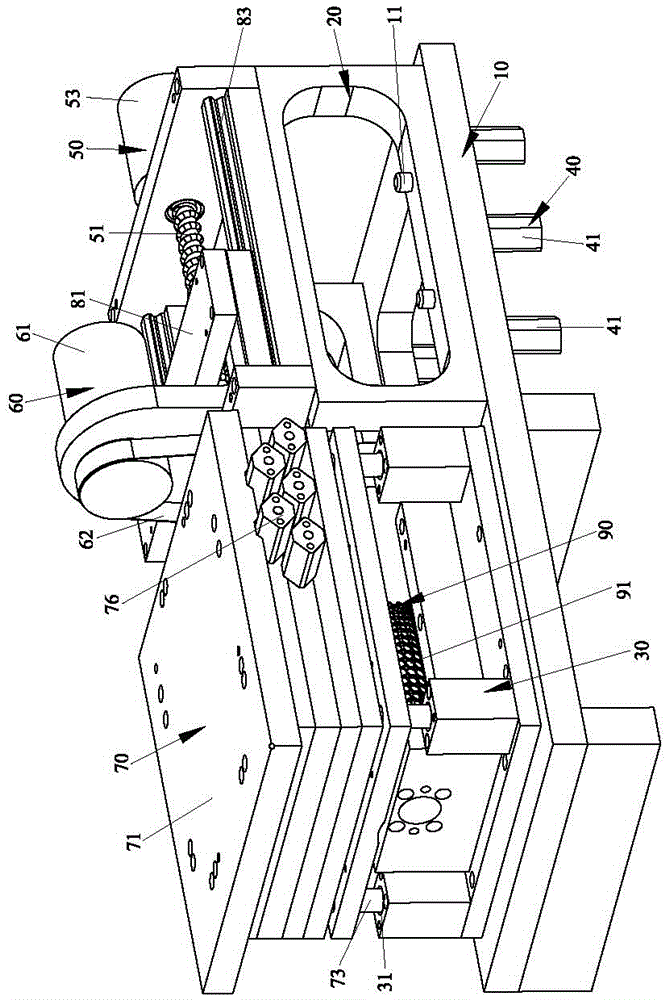

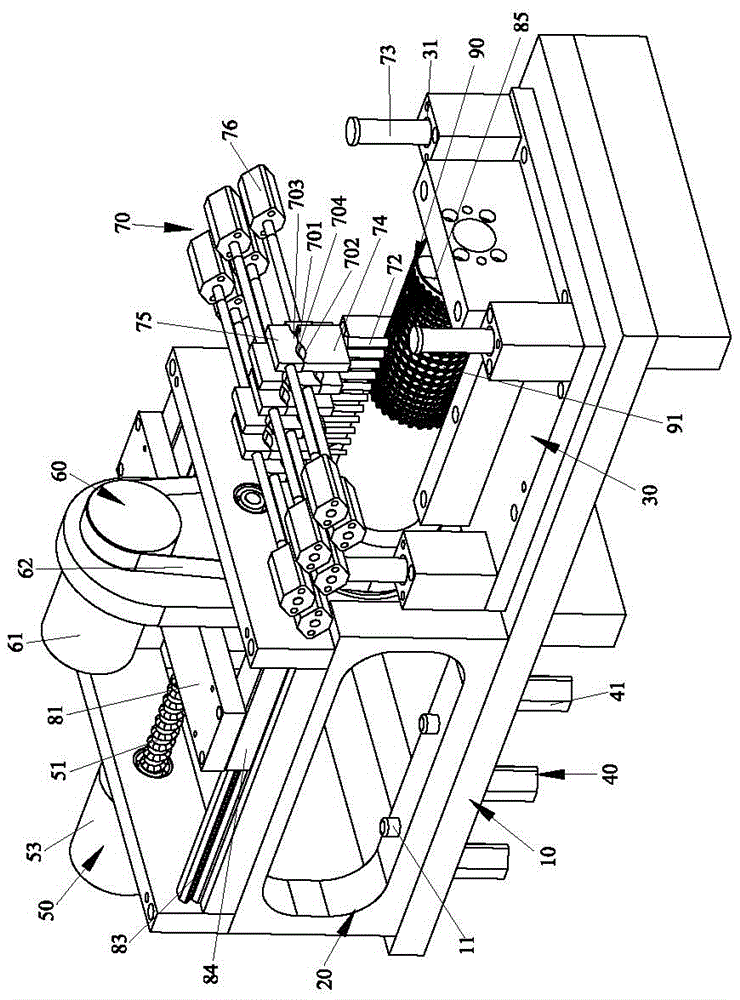

[0042] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a fixed seat 10, a first movable seat 20, a second movable seat 30, a first driving mechanism 40, a second driving mechanism 50, a third The driving mechanism 60 and the stamping die 70 .

[0043] Both the first movable seat 20 and the second movable seat 30 can be arranged up and down on the fixed seat 10 and arranged front and back. In this embodiment, the fixed seat 10 is provided with a guide column 11, and the first movable seat 20 moves up and down along the guide post 11.

[0044] The first movable seat 20 is provided with a sliding seat 81 that can move back and forth, and the sliding seat 81 is provided with a docking piece 82 for connecting and fixing the metal pipe 90. The docking piece 82 is rotatably mounted on the sliding seat 81, and In this embodiment, the first movable seat 20 is provided with two sliding rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com