pneumatic tire

A technology for pneumatic tires and tires, applied in the direction of pneumatic tires, tire parts, tire tread/tread pattern, etc., can solve the problem of unclear tire braking performance and rotation performance, no anisotropy of the pattern, and no variety of patterns Anisotropy and other issues can be improved to improve braking performance and spin performance on ice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

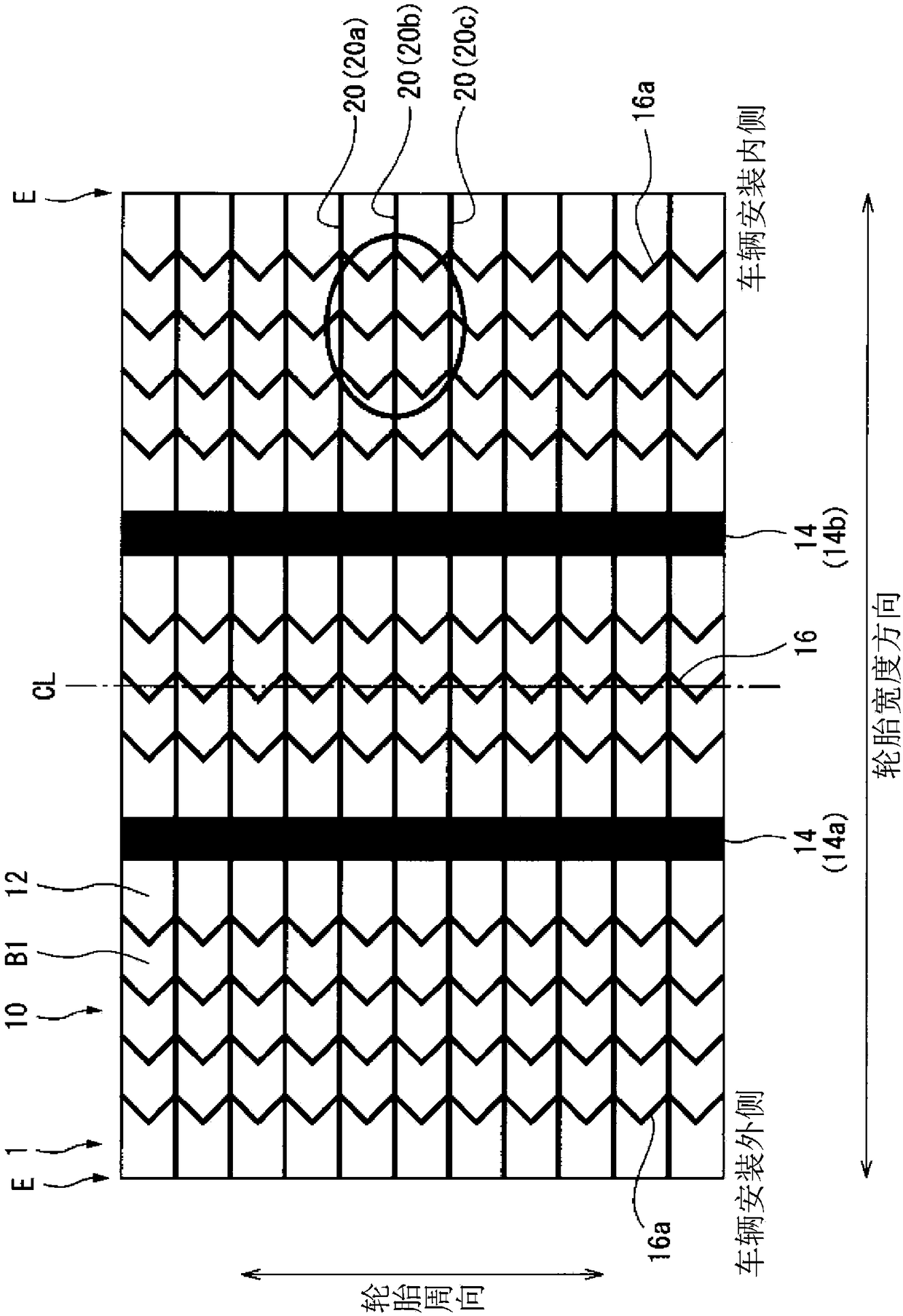

[0026] Basic Embodiment 1 is an embodiment of a pneumatic tire in which a vehicle mounting direction is specified. figure 1 It is a plan view showing the tread portion of the pneumatic tire according to the embodiment of the present invention. The tread portion 10 of the pneumatic tire 1 shown in the figure is made of rubber material (tread rubber), is exposed on the outermost side in the tire radial direction of the pneumatic tire 1 , and its surface constitutes the outline of the pneumatic tire 1 . The surface of the tread portion 10 constitutes a tire tread, that is, a surface on which the vehicle (not shown) on which the pneumatic tire 1 is mounted comes into contact with the ground when running.

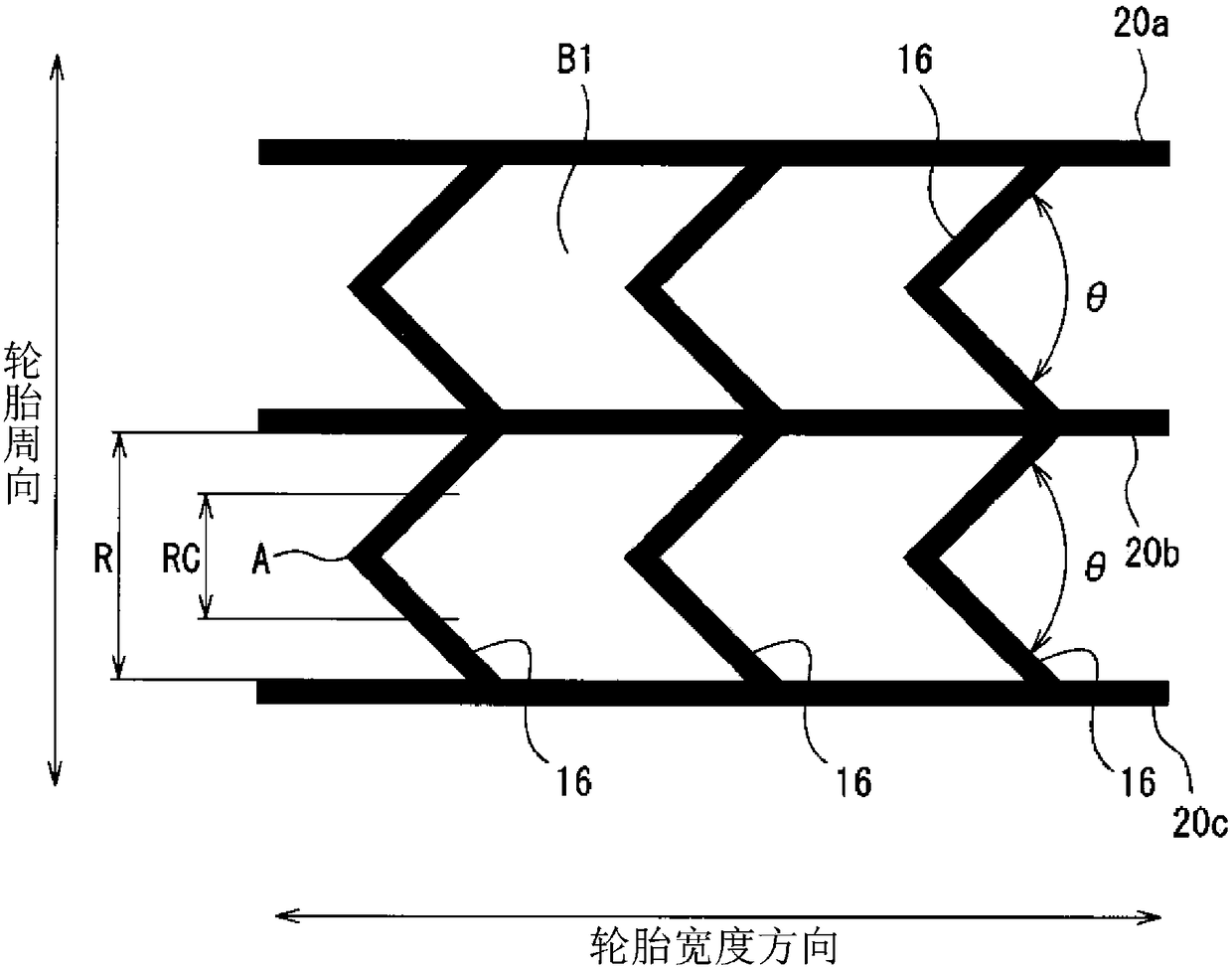

[0027] Such as figure 1 As shown, the tread surface 12 is respectively provided with grooves 14 and 16 extending in the tire circumferential direction and a groove 20 inclined relative to the tire circumferential direction, forming the tread pattern shown in the figure. The sp...

Embodiment approach 2

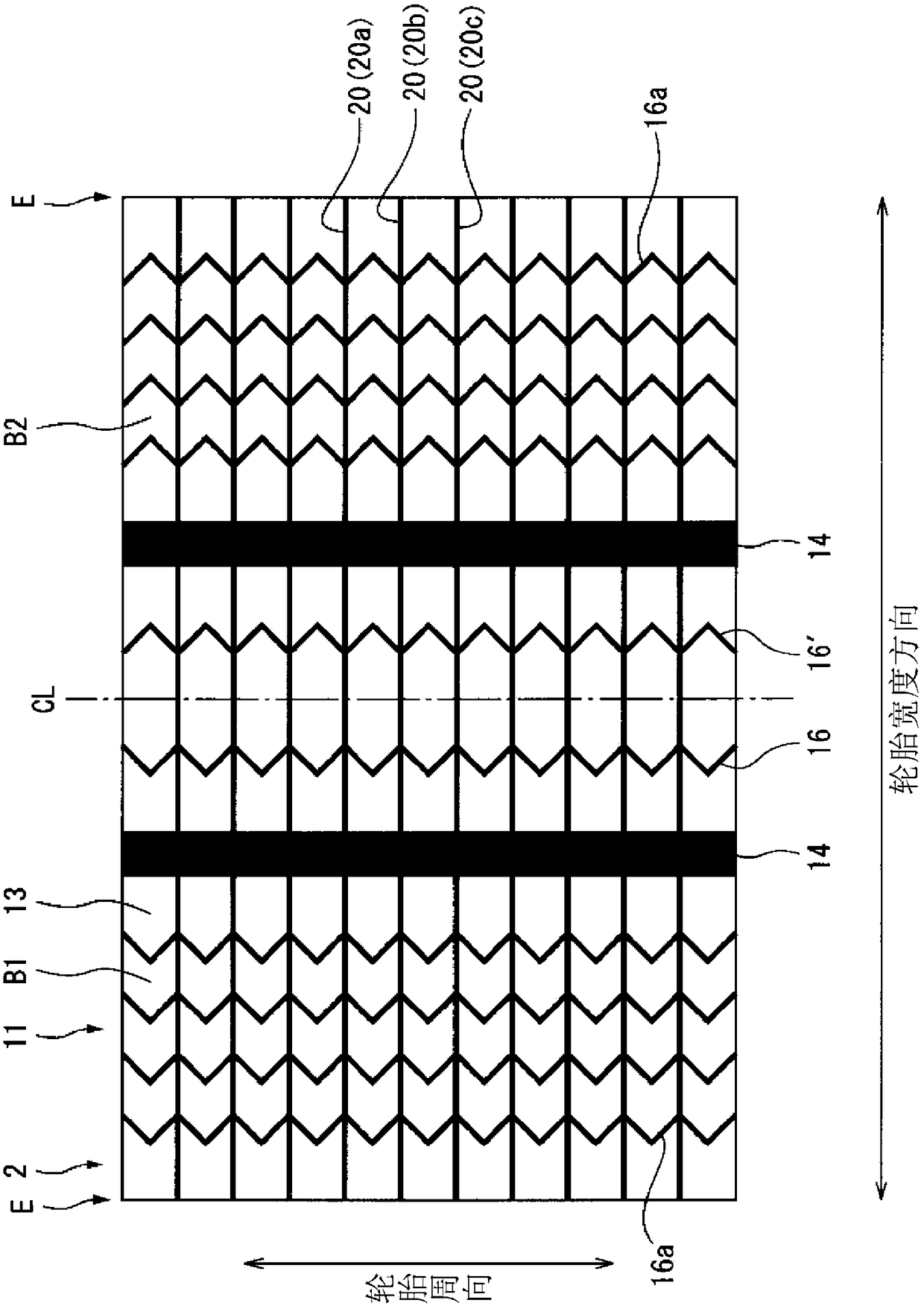

[0050] Basic Embodiment 2 is an embodiment of a pneumatic tire in which a vehicle mounting direction is not specified. image 3 It is a plan view showing the tread portion of the pneumatic tire according to the embodiment of the present invention. The pneumatic tire 1 shown in this figure has a tread pattern that is line-symmetric with respect to the tire equatorial plane CL. The reference symbols shown in the figure, with figure 1 The same reference symbols as those shown indicate the same figure 1 The constituent elements shown are the same as the constituent elements.

[0051] and figure 1 The basic embodiment 1 shown is the same, image 3 The tread portion 11 of the illustrated pneumatic tire 2 is made of rubber material (tread rubber), is exposed on the outermost side in the tire radial direction of the pneumatic tire 2 , and its surface constitutes the outline of the pneumatic tire 2 . The surface of the tread portion 11 is formed as a tread surface 13 , that is, a ...

Embodiment approach

[0056] Next, additional embodiments 1 to 10, which can be arbitrarily implemented with respect to the above-mentioned basic embodiment of the pneumatic tire according to the present invention, will be described.

[0057] (additional embodiment 1)

[0058] In the basic embodiment (basic embodiment 1, 2), preferably figure 1 , 3 The intervals between the narrow grooves 20 in the middle width direction are 0.8 times or more and 1.5 times or less the intervals between the circumferential thin grooves 16 ( 16 ′), respectively (additional embodiment 1).

[0059] Here, the interval between the narrow grooves 20 in the width direction means, for example, the grooves of the narrow grooves 20a, 20b adjacent in the circumferential direction of the tire (or the narrow grooves 20b, 20c adjacent in the circumferential direction of the tire). The distance between the centerlines in the width direction. Likewise, the interval between the circumferential narrow grooves 16 ( 16 ′) refers to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap