Square paper tube machine molded through buckle joint

A paper tube machine and square technology, which is applied in the direction of cardboard winding items, etc., can solve the problems of affecting the use effect and low tube outlet speed, and achieve the effect of fast tube outlet speed and adjustable wall thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

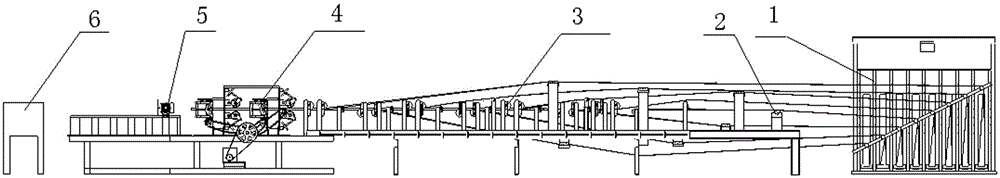

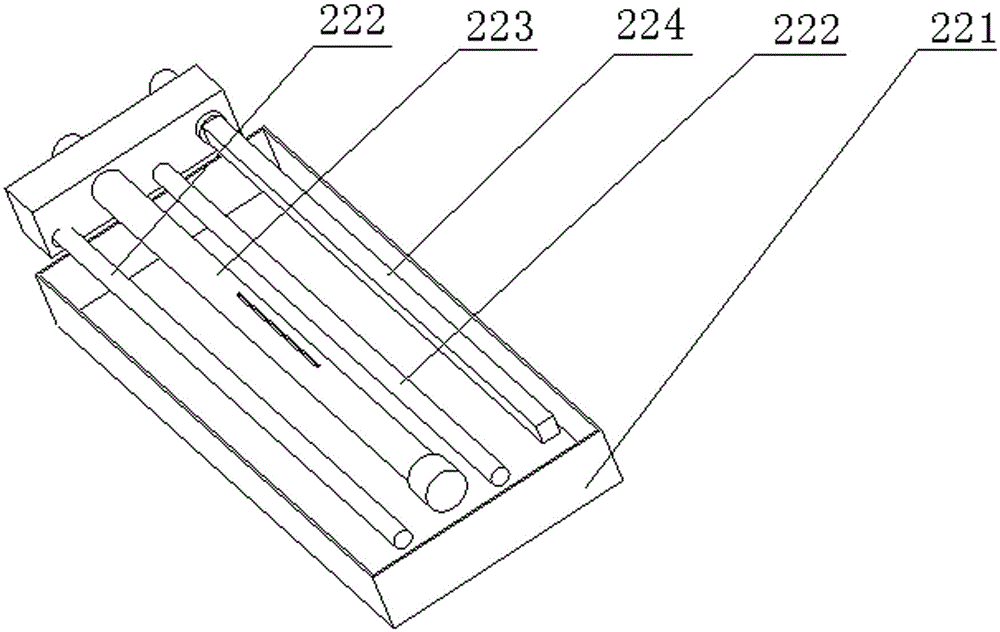

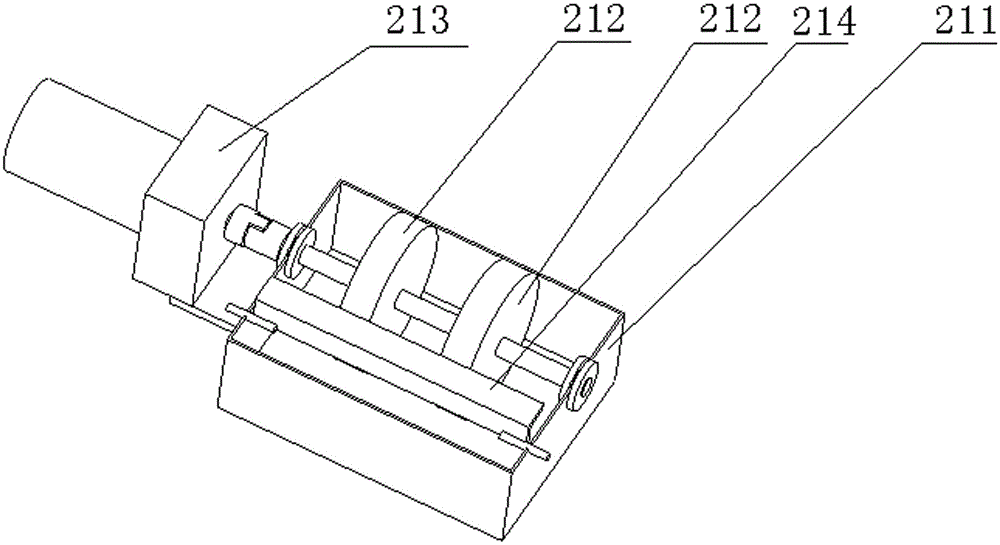

[0033] Such as Figure 1-10 As shown, a buckle forming square paper tube machine, the paper tube machine is sequentially provided with a paper rack 1, a glue application part 2, a buckle forming part 3, a compaction drive part 4, a cutting part 5, and an electrical control box 6; wherein, the glue applicator 2 includes three parts, which are respectively the first glue applicator, the upper glue applicator and the lower glue applicator; the upper glue applicator and the lower glue applicator have the same structure, and are equipped with A glue hopper 221, two paper guide rods 222 are arranged side by side on the glue hopper 221, a rubber hose 223 is arranged above the paper guide rods 222, and a rubber scraper 224 is arranged on one side of the rubber hose 223 ; The first glue applicator is provided with a rubber hopper 211, and the rubber hopper 211 is provided with a rubber wheel 212, and the rubber wheel 212 is connected with the gluing transmission device 213 through a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com