A feed supply device controlled and locked by a motor

A motor control and supply device technology, applied in the field of feed, can solve the problems of waste of feed, inconvenience of unified maintenance and operation, fixed structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

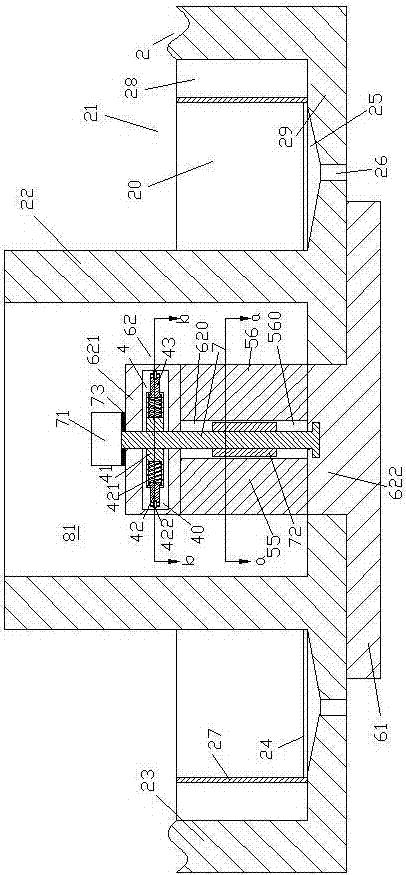

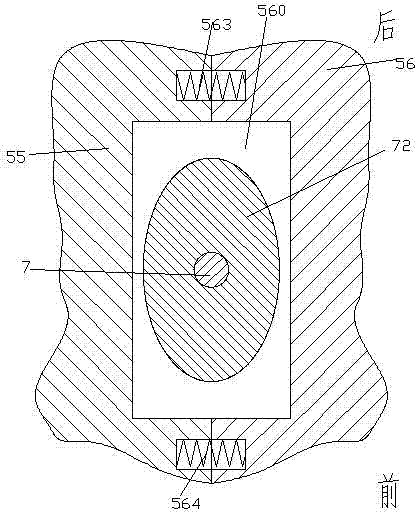

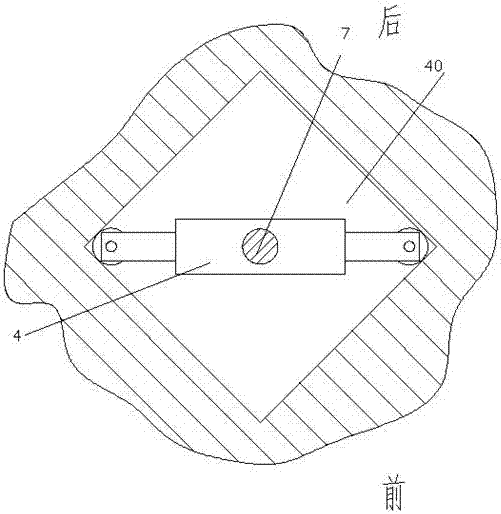

[0011] Combine below Figure 1-3 The present invention will be described in detail.

[0012] According to an embodiment, a feed supply device controlled and locked by a motor includes a vertical fixed column part 62 with a carrying chassis 61 and a fixed connection with the carrying chassis 61, and the fixed column part 62 includes a horizontal The telescopic through hole 620 of the slider extending in the direction, the top wall part 621 located on the upper side of the telescopic through hole 620 of the slider, and the column root located on the lower side of the telescopic through hole 620 of the slider and directly connected with the carrying chassis Part 622, two locking sliders 55, 56 symmetrical to the axis of the fixed cylinder part 62 are slidably arranged in the slider telescopic through hole 620, and the two locking sliders 55, 56 can be mutually Move toward each other and retract into the telescopic through hole 620 of the slider and lean against each other. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com