Scroll compressor.

A technology of scroll compressors and scroll disks, which is applied in the direction of rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems of increased movement speed, sharpness, and variable height of the cycle gap shape, and achieves Effect of less air recompression, reduced leakage velocity, and lower operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

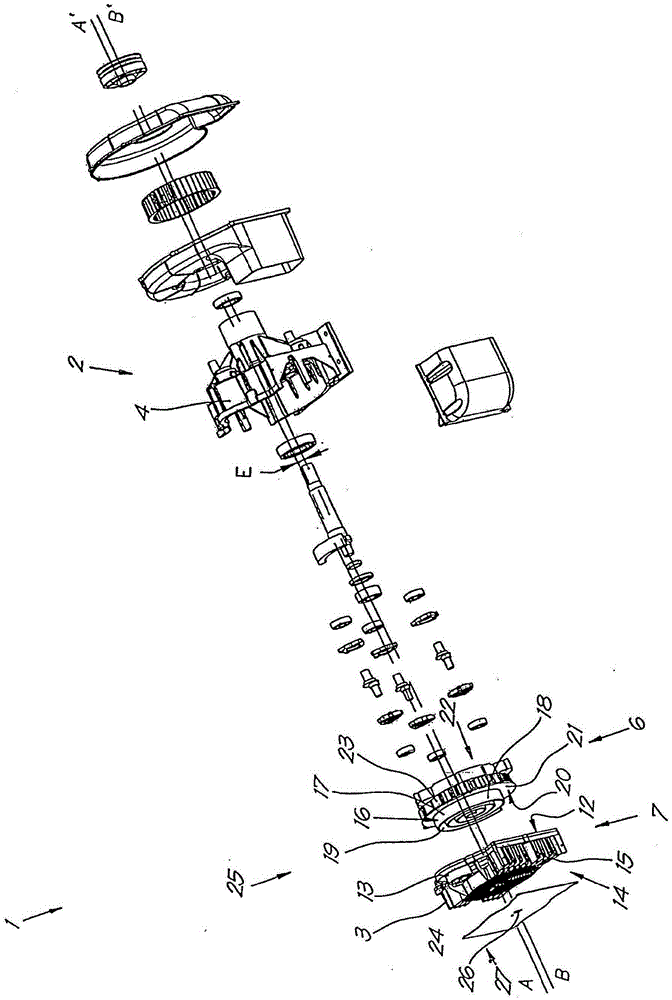

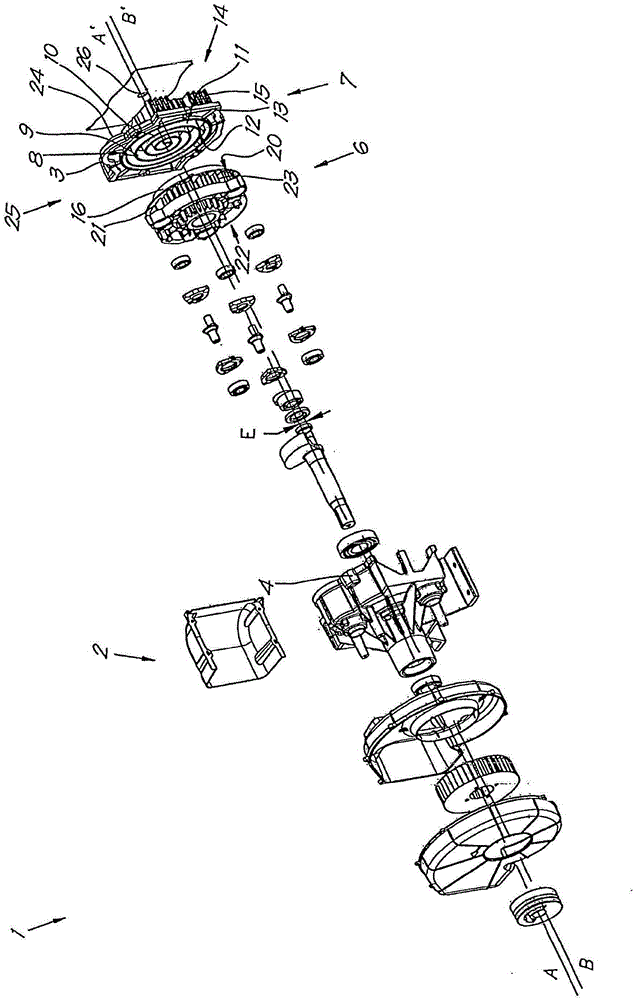

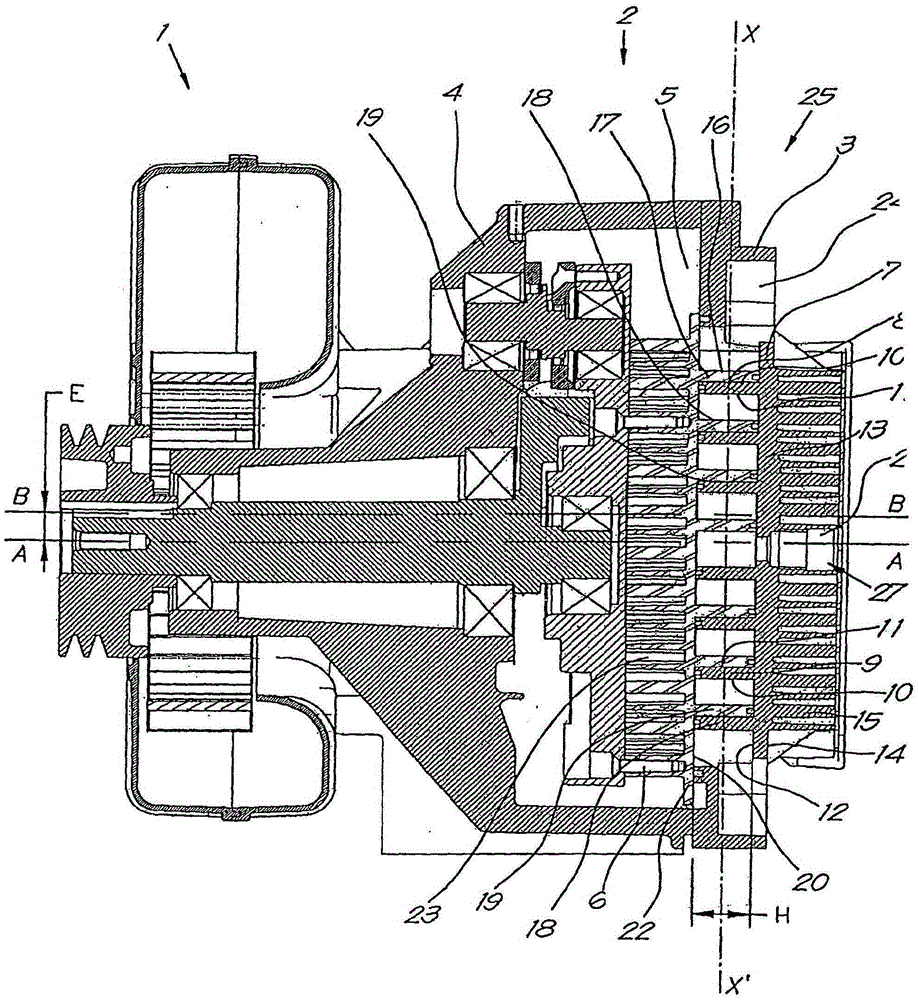

[0095] exist Figures 1 to 3 These elements shown in Fig. 1 give an oil-free scroll compressor 1 in an expanded and assembled state, and of the type to which the present invention relates.

[0096] The scroll compressor 1 has a housing 2, which in this case essentially consists of two parts, more specifically a part 3 and a part 4, which in the assembled state surround a space 5 in which a rotor 6 is fixed. .

[0097] Furthermore, part 3 forms a stator 7 which is immovably mounted in casing 2 and which comprises a fixed stator scroll with a central stator axis AA'.

[0098] The stator scroll 8 is formed by a stator strip 9 having two stator wings 10 and 11, namely an outward stator wing 10 and a stator scroll The center or central axis AA' of the disc 8 is turned inwardly towards the stator flanks 11 .

[0099] Furthermore, the stator band 9 is helically wound along its length and is fixed upright at a height H on the first side 12 of the stator plate 13 .

[0100] Cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com