scroll compressor

一种涡旋式压缩机、涡旋盘的技术,应用在旋转活塞式机械、旋转活塞式泵、机械设备等方向,能够解决运动速度增大、尖锐、难以预先评估等问题,达到操作温度低、泄漏速度减小、空气重新压缩少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

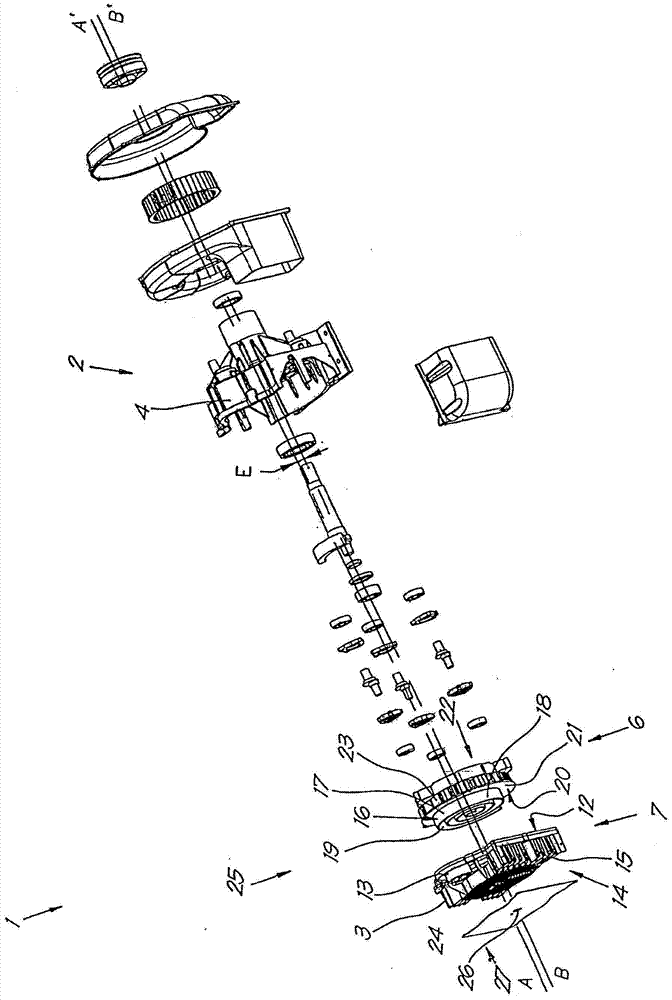

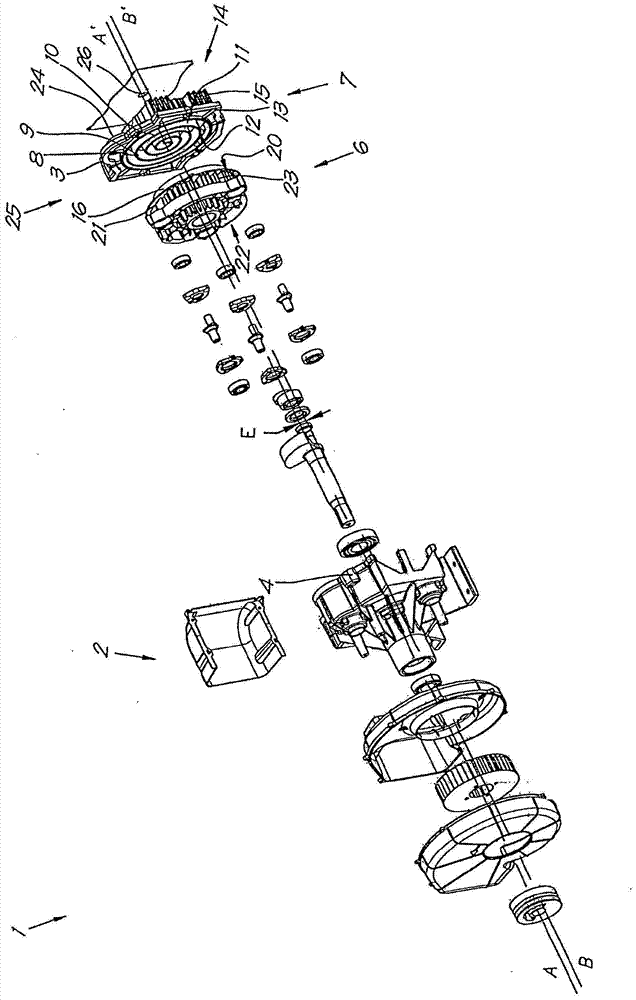

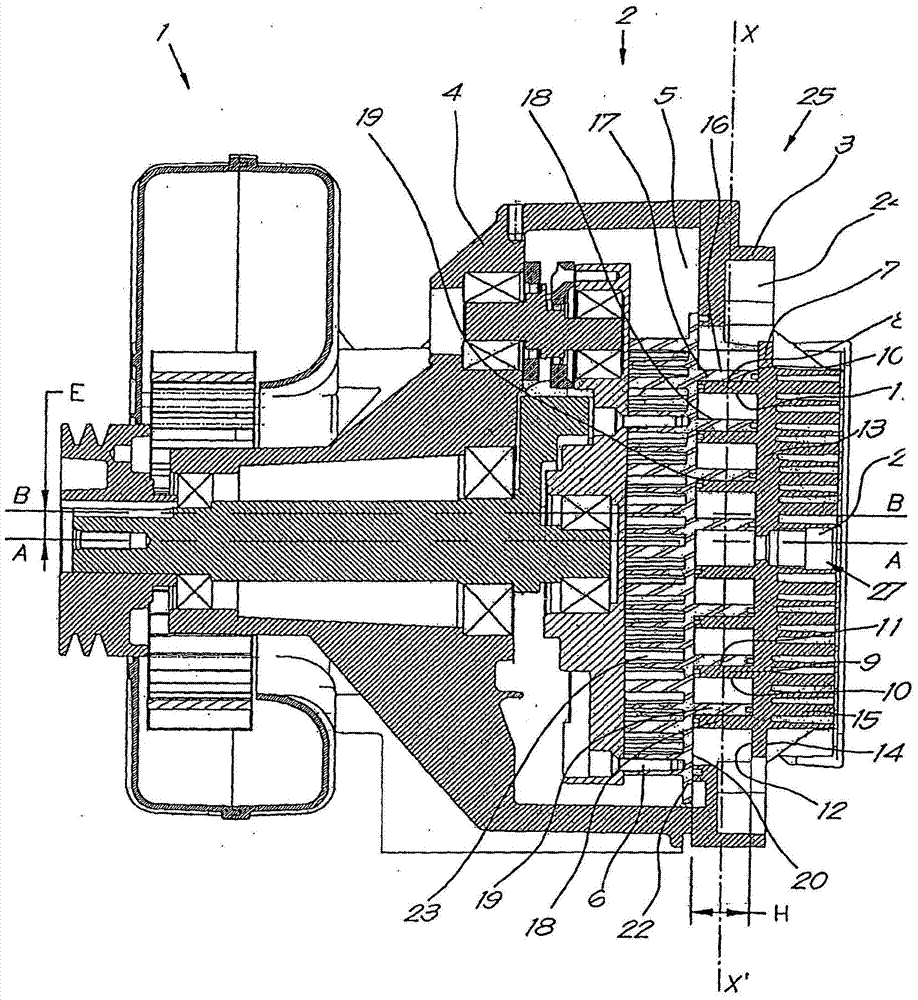

[0095] exist Figures 1 to 3 These elements shown in Fig. 1 give an oil-free scroll compressor 1 in an expanded and assembled state, and of the type to which the present invention relates.

[0096] The scroll compressor 1 has a housing 2, which in this case essentially consists of two parts, more specifically a part 3 and a part 4, which in the assembled state surround a space 5 in which a rotor 6 is fixed. .

[0097] Furthermore, part 3 forms a stator 7 which is immovably mounted in casing 2 and which comprises a fixed stator scroll with a central stator axis AA'.

[0098] The stator scroll 8 is formed by a stator strip 9 having two stator wings 10 and 11, namely an outward stator wing 10 and a stator scroll The center or central axis AA' of the disc 8 is turned inwardly towards the stator flanks 11 .

[0099] Furthermore, the stator band 9 is helically wound along its length and is fixed upright at a height H on the first side 12 of the stator plate 13 .

[0100] Cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com