Transformer assembly tool

A technology for assembling tooling and transformers, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc. It can solve the problems of difficult installation and high requirements for operating experience of operators, and achieve the effect of strong versatility and simple and reliable assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

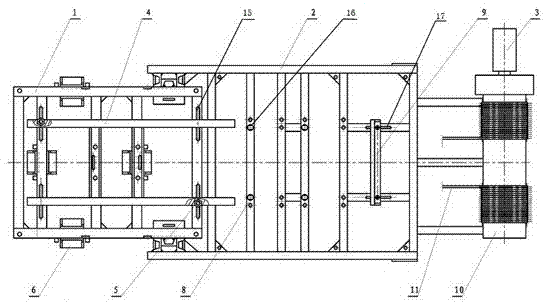

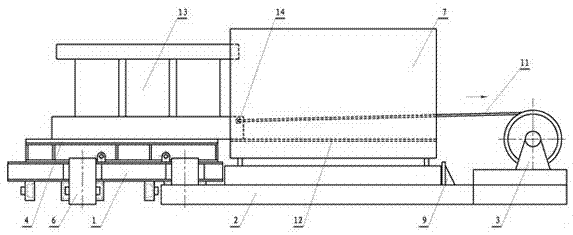

[0021] Such as Figure 1-2 As shown: the transformer assembly tooling consists of three parts: the body placement frame 1, the base 2 and the traction motor 3. Two support rails 4 are installed on the body placement frame 1, and the connection holes for fixing the support rail 4 are perpendicular to the rails. The long waist-shaped gauge adjustment hole 15 in the direction, the distance between the two support rails 4 can be adjusted, and the pneumatic lifting support seat 6 is installed on the body placement frame 1, and its output end is connected with the body placement frame 1, which can be adjusted The height of the support rail 4. The device body placement frame 1 is in contact with one end of the base 2 of the fixed explosion-proof casing 7. The base 2 is provided with a limit hole 16 and a baffle adjustment hole 17. The limit hole 16 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com