Remoulding soil sample preparation device

A technology for preparing devices and reshaping soil, which is applied in the preparation of test samples, measuring devices, sampling, etc., can solve the problem that the sample preparation device is no longer applicable, and achieve the effect of improving the efficiency and accuracy of sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing of description, the present invention will be further described.

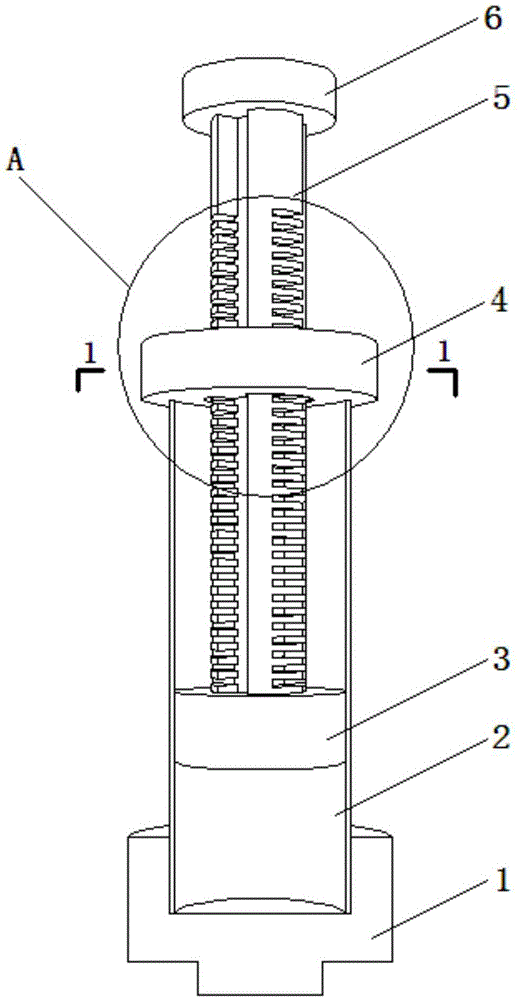

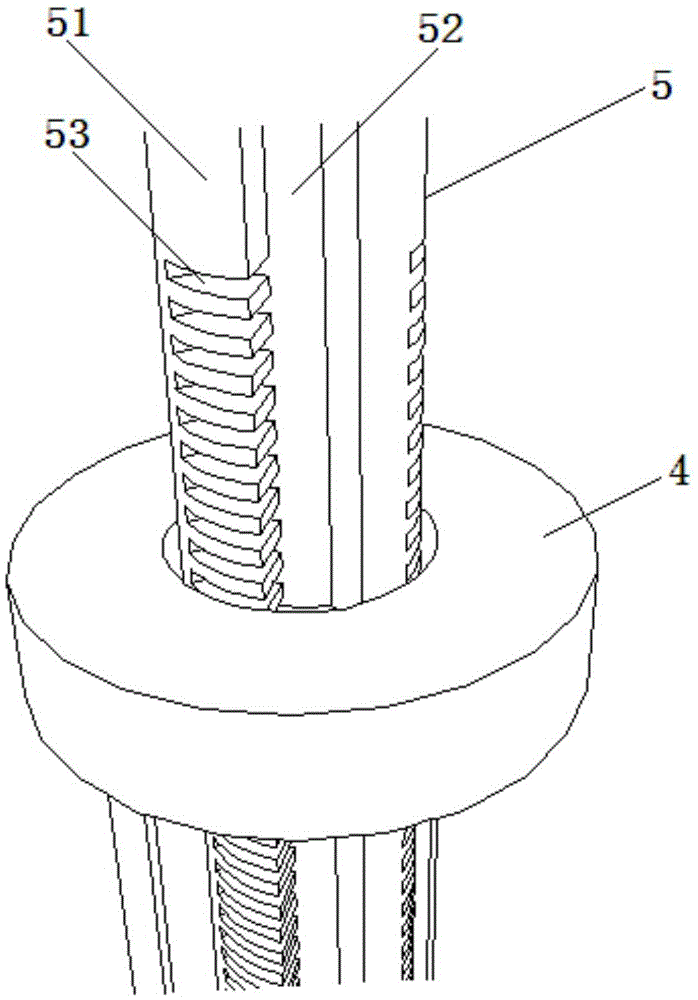

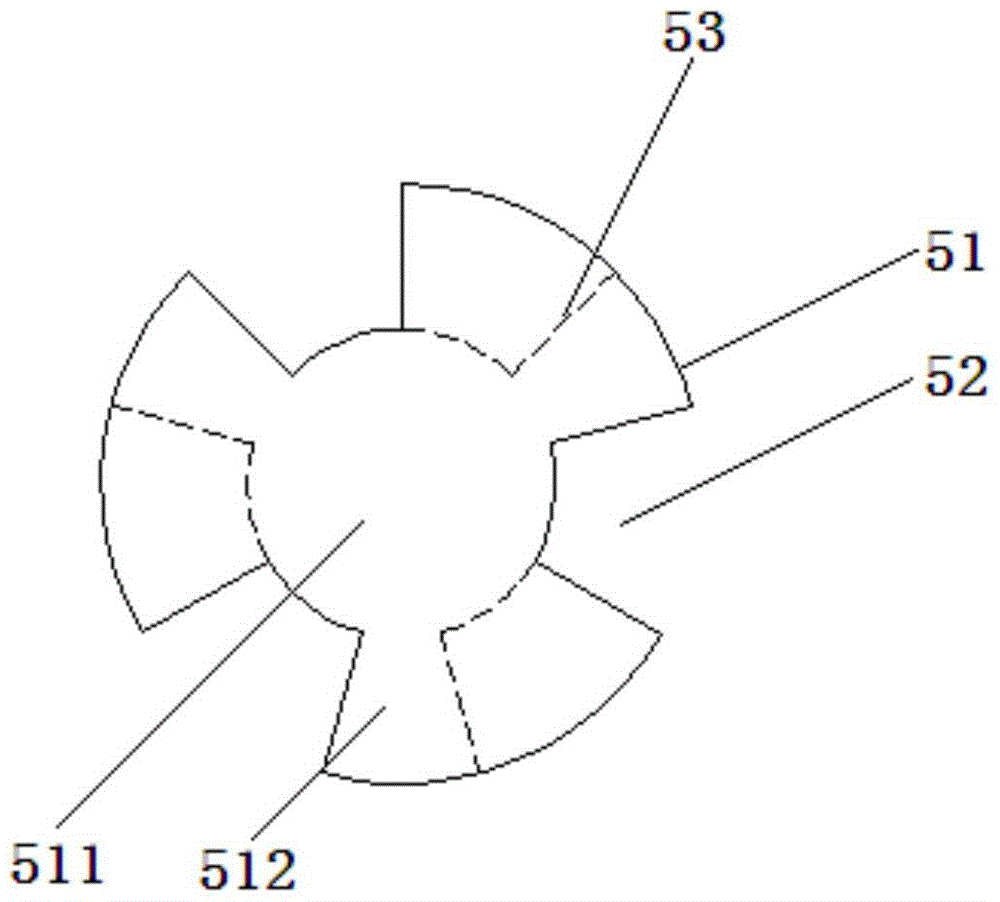

[0034] Such as figure 1 and figure 2 As shown, a remodeling soil sample preparation device includes a base 1, a sample holding mold 2, a compactor 3, a positioner 4, a clamping rod 5 and a pressure plate 6; all parts are made of stainless steel, and the positioning The device 4 is preferably made of high-strength stainless steel in consideration of the larger factor of concentrated stress.

[0035] The sample holding mold 2 is fixed on the base 1, and the top surface of the base 1 is provided with a base recess of a circular structure for the bottom of the sample holding mold 2 to fall into, which helps to fix the sample holding mold 2 better.

[0036] The positioner 4 is sleeved on the clamping rod 5, and moves vertically along the rod body of the clamping rod 5, and then rotates in the horizontal direction to set the angle, and then clamps on the clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com