A high-throughput micro-hybrid chip based on alternating current electrothermal and its application

A high-throughput, micro-mixing technology, used in laboratory containers, laboratory utensils, chemical instruments and methods, etc., can solve problems such as inability to uniformly mix fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

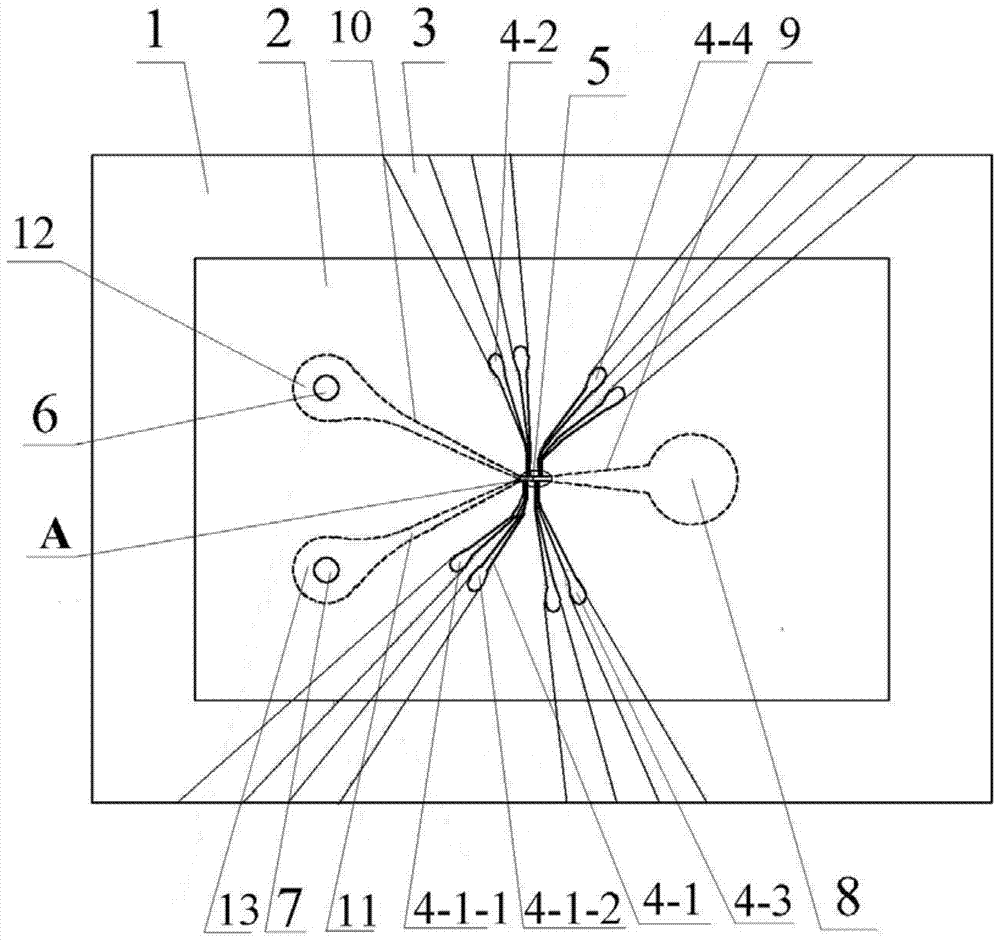

[0069] Specific implementation plan one: combine figure 1 and 2 Describe this embodiment in detail. This embodiment is a high-throughput micro-hybrid chip based on alternating current electric heating. The high-throughput micro-hybrid chip based on alternating current electric heating consists of a glass substrate 1 and a PDMS cover sheet 2;

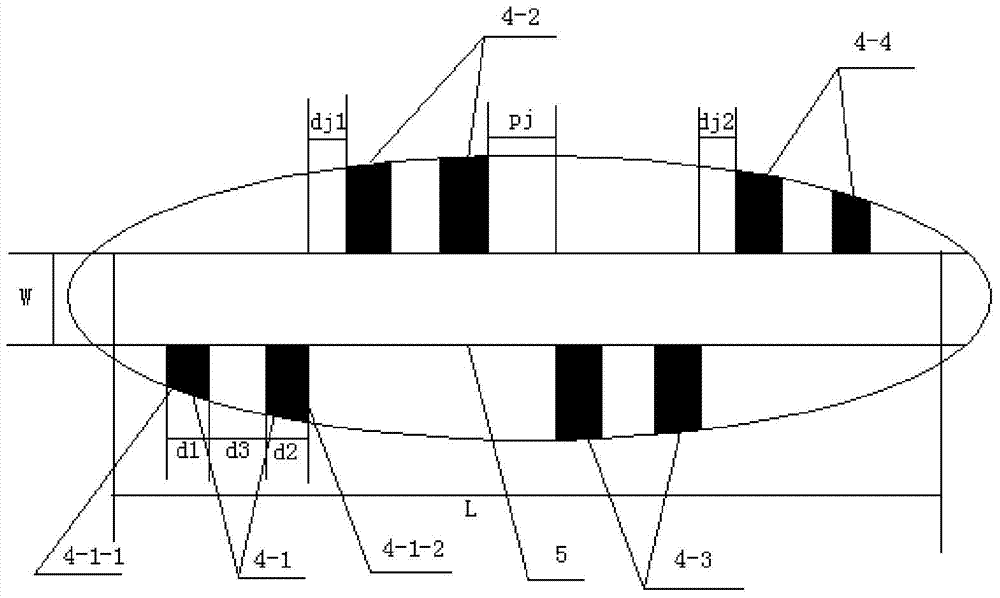

[0070] The surface of the glass substrate 1 is provided with a first group of three-dimensional electrodes 4-1, a second group of three-dimensional electrodes 4-2, a third group of three-dimensional electrodes 4-3, a fourth group of three-dimensional electrodes 4-4 and ITO electrode leads 3;

[0071] The ITO electrode leads 3 are obtained after corrosion of the ITO conductive film on the surface of the glass substrate 1; the first group of three-dimensional electrodes 4-1, the second group of three-dimensional electrodes 4-2, and the third group of three-dimensional electrodes 4-3 1. The thickness of the fourth group of three-dimension...

specific Embodiment approach 2

[0080] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the angle between the first flow channel 10 and the second flow channel 11 is 60°. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0081] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the diameter of the first circular inlet through hole 6 is 1 mm; the diameter of the second circular inlet through hole 7 is 1 mm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com