Leveling and overlaying machine for raw ceramic chip through hole column protrusions

A technology of through-hole columns and green ceramic sheets, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of easy pressure loss of guide rails, and achieve the effect of leveling and positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

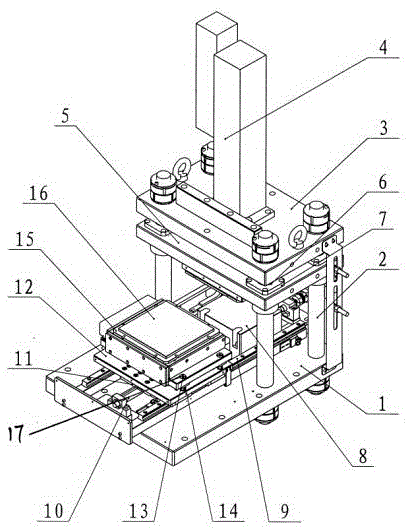

[0009] The present invention is described in detail below in conjunction with accompanying drawing:

[0010] A bulging, leveling and laminating machine for through-hole columns of green ceramic sheets, comprising a rectangular base 1, on which four guiding and supporting columns 2 are arranged, and the four guiding and supporting columns 2 are arranged in parallel to each other, and constitute a In the shape of a cuboid, a press table fixing plate 3 is fixedly arranged on the top of the four guiding support columns 2, and a pneumatic hydraulic cylinder 4 is arranged on the pressing table fixing plate 3, and the four corners of the rectangular upper pressing table 5 are respectively arranged There is a linear bearing installation hole 6, and a linear bearing 7 is arranged in the linear bearing installation hole 6, and the guide support column 2 is movably arranged in the linear bearing 7, and the top end of the extending shaft protruding downward of the pneumatic hydraulic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com