Filling valves for filling containers to be filled with filled products

A filling valve and product technology, applied in bottle filling, packaging, liquid bottling, etc., can solve the problems of impossible filling and difficulty, and achieve the effect of reducing the tendency of dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

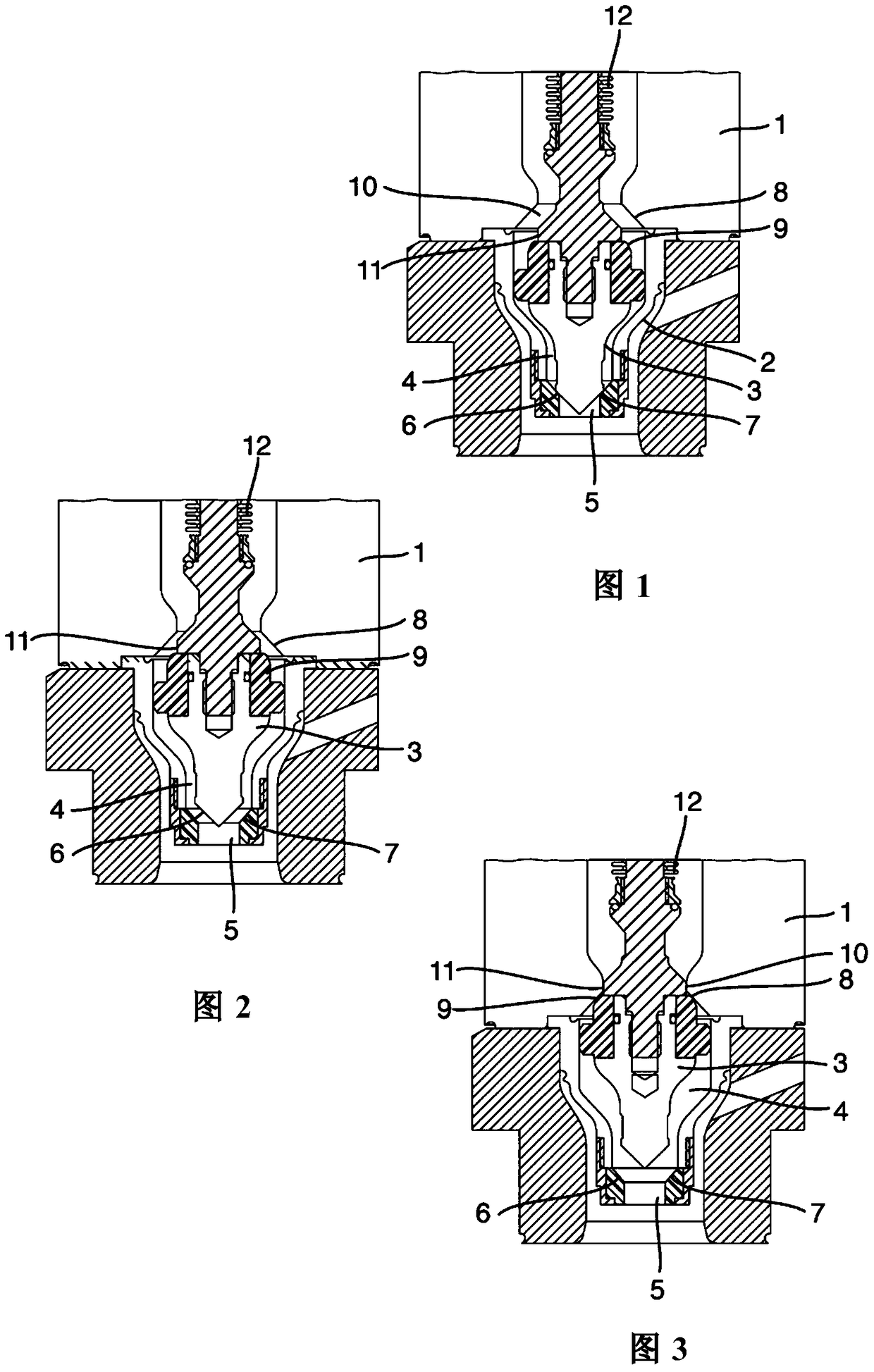

[0035] A preferred exemplary embodiment is subsequently described with reference to the drawings. Here, identical, similar or identically acting components in different drawings are denoted by the same reference numerals, and repeated descriptions of these components are partially omitted in order to avoid redundancy.

[0036] figure 1 The filling valve in is shown in cross section and has a bottom part 1 of the filling valve, a product outflow sleeve 2 and a valve cone 3 . A generally cylindrical valve cone 3 is located in the cavity of the product outlet sleeve 2 and forms an annular gap 4 through which the filling product flows to the product outlet 5 in the open valve body position. The annular gap 4 thus forms the flow path of the filling product through the filling valve.

[0037] In the region of the product outlet 5 , ie in its lower region, the valve cone 3 has a sealing contour 6 which, in the closed state, is accommodated in a corresponding complementary contour o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com