Comprehensive optimization method of gap and overlap during strip shearing

A technology of overlap and clearance, used in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

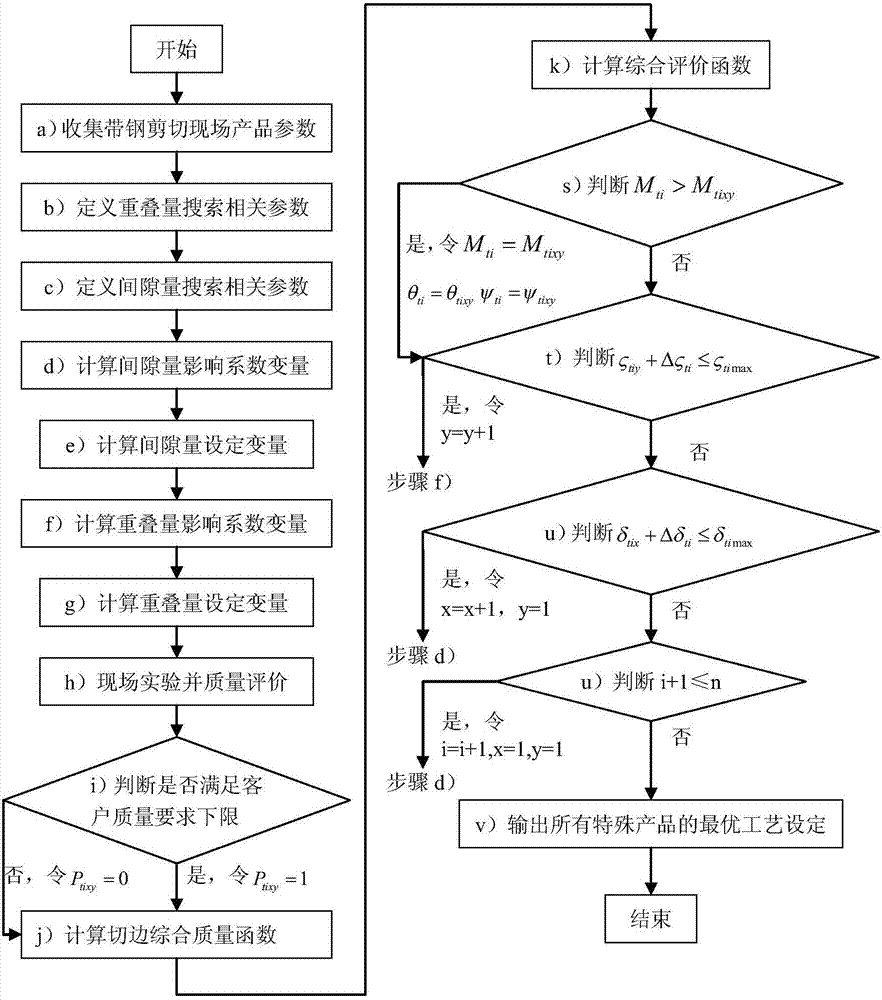

[0027] In order to further illustrate the application process of the technology of the present invention, taking a certain finishing unit process section as an example, the application process and use effect of the method of the present invention on the spot are introduced in detail. The overall flow is as follows figure 1 Shown:

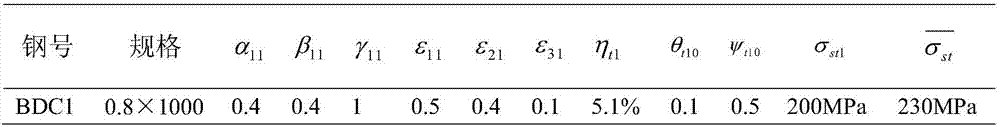

[0028] (1) Collect product parameters, product number i=1, collect relevant parameters as follows:

[0029] Table 1 Typical strip product parameters of a finishing unit

[0030]

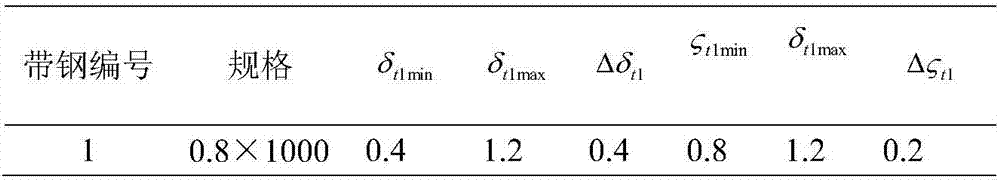

[0031] (2) Define the relevant parameters, and determine the relevant parameters according to the on-site working conditions as shown in Table 2;

[0032] Table 2 Typical strip steel working condition parameters of a finishing unit

[0033]

[0034] (3) Initialize relevant parameters and perform calculations and experiments.

[0035] 3a) Now x=1, y=1, calculate δ tix =0.4, θ tix =0.08mm, ψ tiy = 0.44mm, set the gap and overlap according to the calculated valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com