Curing procedure oriented method for monitoring interfacial force between composite materials and molds

A composite material and interfacial force technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as low precision and complicated measurement process, and achieve the effect of repeated monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

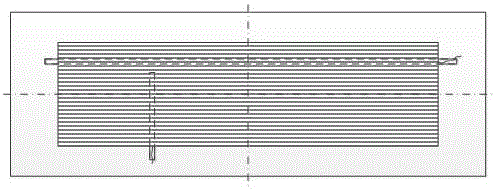

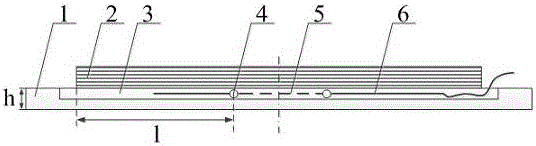

[0029] Such as Figure 1-2 shown.

[0030] A method for monitoring the interface force between a composite material and a mold oriented to a curing process, comprising the following steps:

[0031] First, a plurality of grooves that can be continuously or discontinuously distributed in any direction are arranged on the surface of the mold in contact with the composite material. The groove direction is preferably distributed along the length and width of the mold; The height of the section is 0.05mm-0.25mm larger; the groove can adopt a rectangular parallelepiped or cylindrical structure;

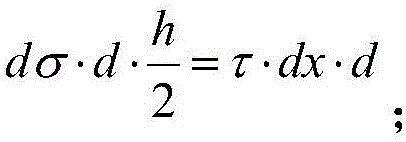

[0032] Secondly, put the strain sensor into the groove, and seal the surface of the groove at the same time, so that the measurement area of the sensor has no contact with the walls around the groove, and the two ends of the measurement area are fixed in the groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com