Front housing, electric connector adopting front housing, and electric connector assembly

An electrical connector and front housing technology, applied in the direction of conductive connection, connection, electrical components, etc., can solve the problem that the size of the electrical connector has a great influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

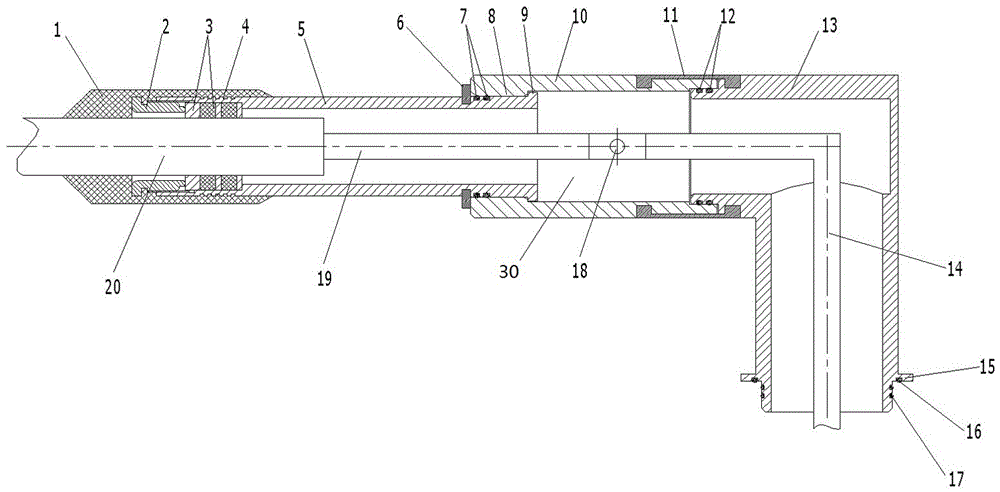

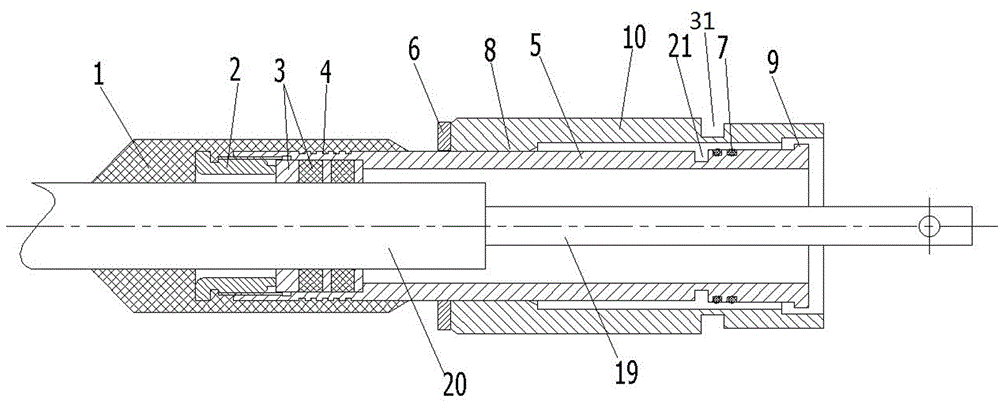

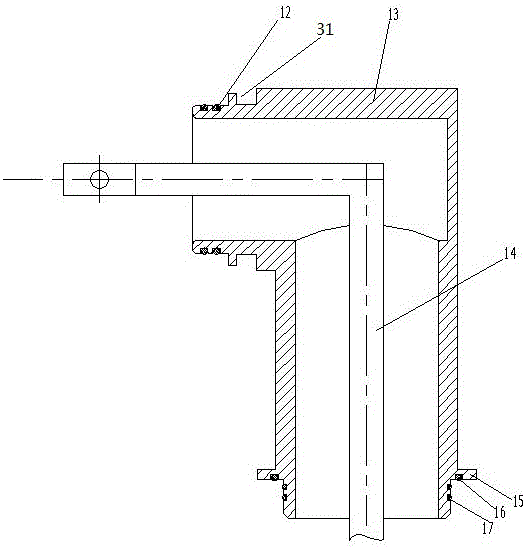

[0022] Examples of electrical connector assemblies are Figure 1~3 Shown: including a first cable, a second cable and an electrical connector, the first cable includes a first cable core 20 and a first connection row 19 connected to the rear end of the first cable core 20, the second cable includes a second connection row 14, the first connecting row 19 and the second connecting row 14 are all copper bars, and the second connecting row 14 is a right-angled L-shaped structure. Through the screw connection holes 18 for the connection of the first connection row and the second connection row, the screw connection holes are waist-shaped holes extending in the front-rear direction. The electrical connector includes a front housing and a rear housing 13. The front housing includes a fixed housing 5 spaced from the rear housing 13 in use. The fixed housing has a first inner hole for the first cable to pass through. The housing 13 has a second inner hole for the second cable to pass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com