A transmission line inspection robot mechanism adapted to large span

A technology for inspection robots and transmission lines, which is applied in the direction of manipulators, program-controlled manipulators, overhead lines/cable equipment, etc., can solve the problems of long obstacle-crossing time and complicated process, and achieve short obstacle-crossing time and large obstacle-crossing distance , the effect of reducing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

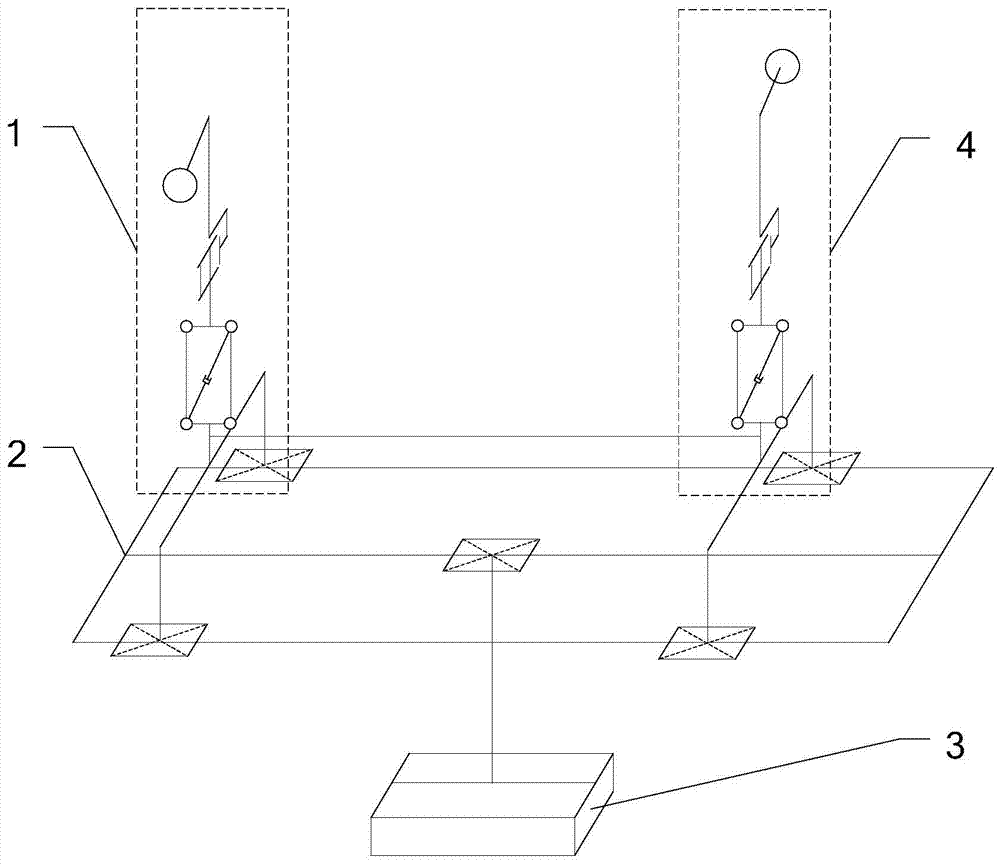

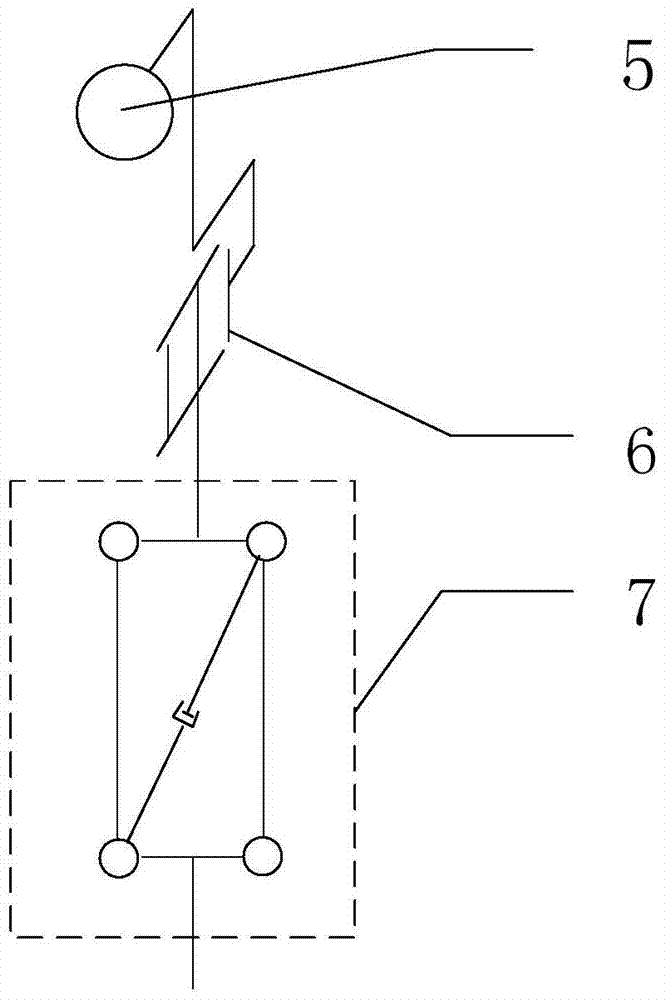

[0027] Such as figure 1 and image 3 As shown, the present invention includes a first guide rail 2, a forearm 1 and a rear arm 4 respectively installed on the first guide rail 2, and a power control box 3 that can reciprocate along the first guide rail 2 and adjust the center of mass of the inspection robot mechanism. , the forearm 1 is identical in structure with the rear arm 4, and can reciprocate on the first guide rail 2, and both include a traveling mechanism that walks on the power line, a rotating joint 6 and a deformation mechanism 7 that drive the traveling mechanism to rotate. One end of the deformation mechanism 7 is connected to the first guide rail 2 and can slide on the first guide rail 2 , and the other end of the deformation mechanism 7 is connected with the running mechanism through the rotary joint 6 .

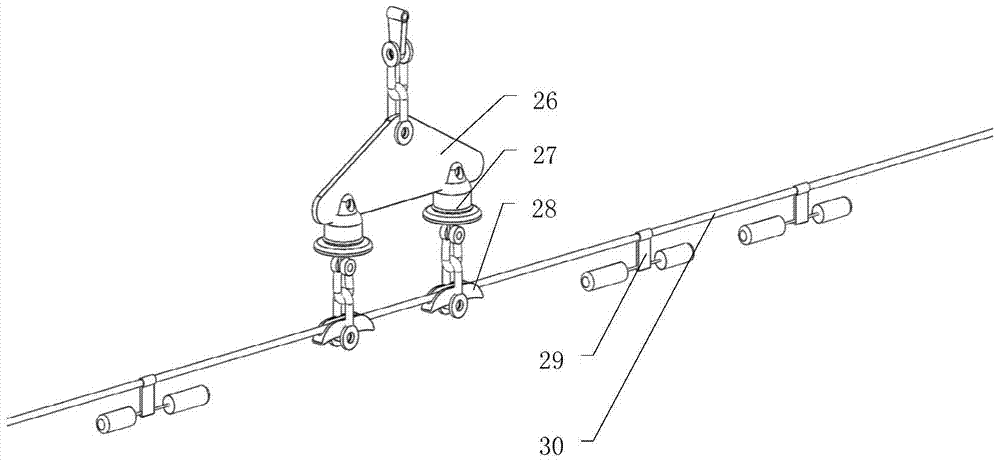

[0028] Such as Figure 4 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com