body reinforcement structure

A technology for strengthening the structure and the body, applied in the directions of the substructure, the superstructure, the subassembly of the superstructure, etc., can solve the problem of inability to input load transmission, etc., and achieve the effect of improving the load transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

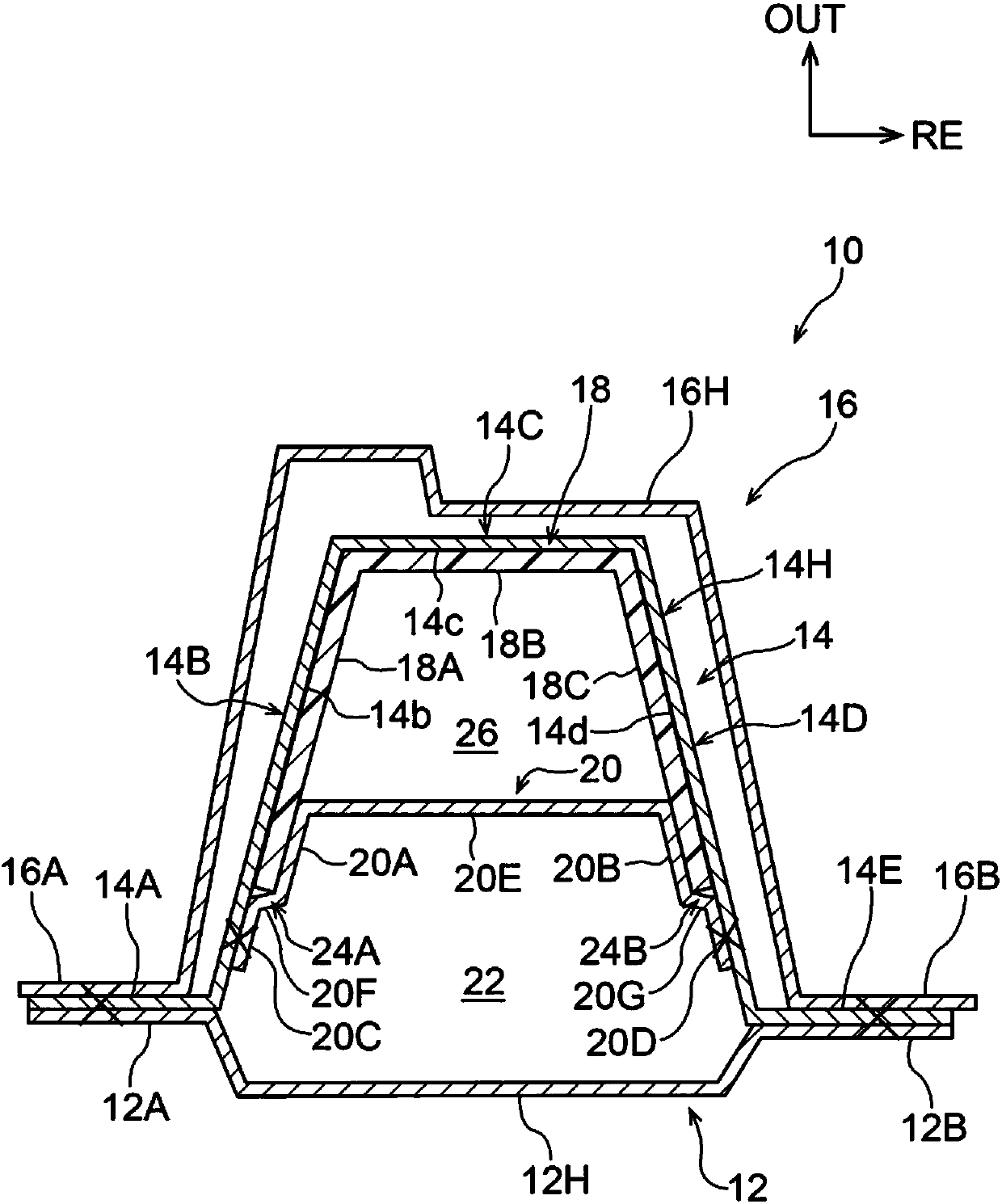

[0037] use Figure 1 to Figure 4 , the vehicle body reinforcement structure according to the first embodiment of the present invention will be described. In addition, in figure 1In , arrow RE indicates the vehicle rear side, and arrow OUT indicates the vehicle width direction outer side.

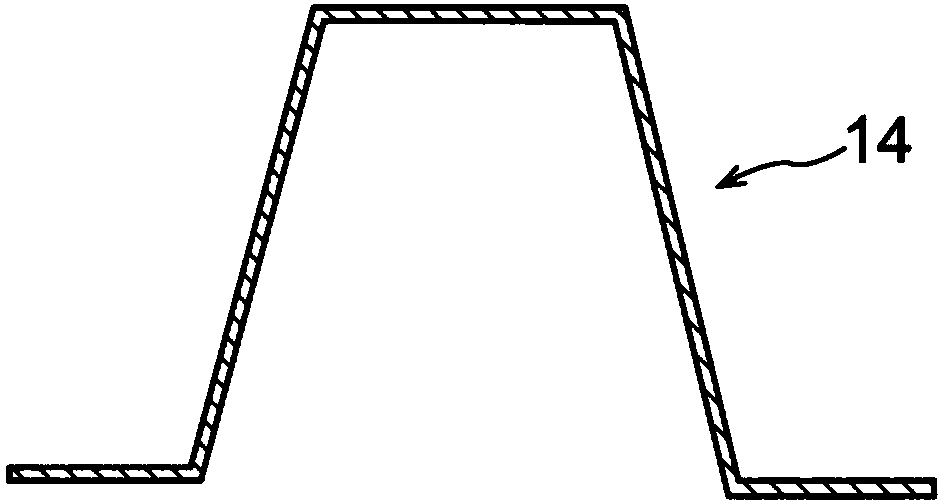

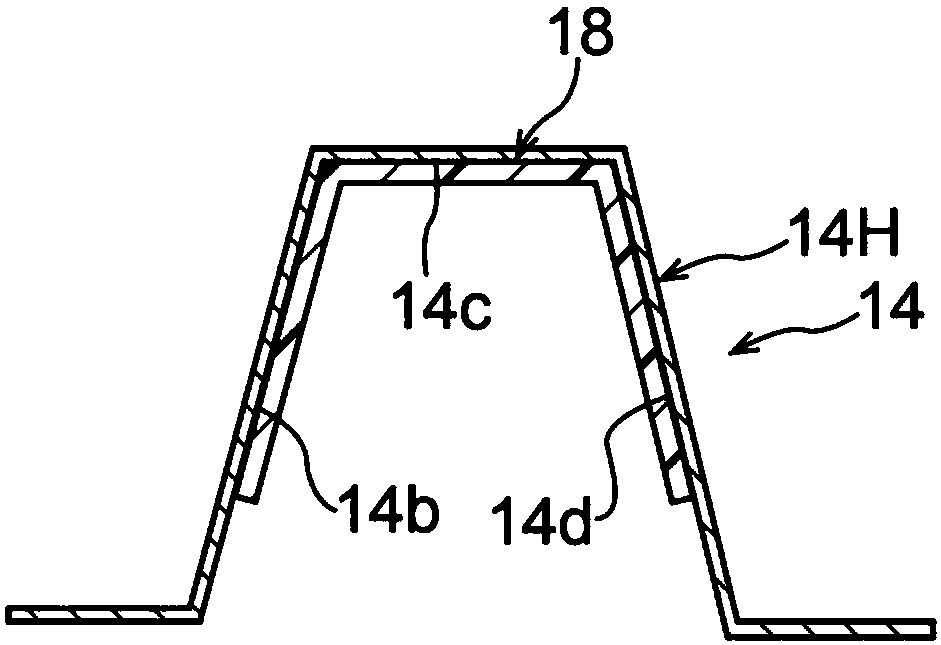

[0038] figure 1 The center pillar 10 to which the vehicle body reinforcement structure according to this embodiment is applied is illustrated in a horizontal cross-sectional view. As shown in the figure, the center pillar 10 includes a metal (in this embodiment, steel) inner panel 12 constituting its inner portion in the vehicle width direction. The inner panel 12 is formed in a top hat shape that opens outward in the vehicle width direction when viewed in horizontal cross-section, and includes a substantially U-shaped main body portion 12H that opens outward in the vehicle width direction when viewed in horizontal cross-section. A front flange portion 12A is formed to bend and extend to...

no. 2 approach

[0069] Next, use Figure 5 Next, a vehicle body reinforcement structure according to a second embodiment of the present invention will be described. Figure 5 12 is a horizontal cross-sectional view of the center pillar 30 to which the vehicle body reinforcement structure according to the present embodiment is applied (corresponding to that of the first embodiment). figure 1 diagram). As shown in the figure, in the center pillar 30, the second reinforcing member 32 as the second reinforcing member arranged to prevent the first reinforcing member 18 from falling off has a connecting portion 34 instead of the connecting portion 20E( figure 1 Reference), this point is related to the center pillar 10 ( figure 1 Reference) is different. The other structures are the same as those of the first embodiment. Therefore, the same reference numerals are assigned to the same constituent parts as those in the first embodiment, and description thereof will be omitted.

[0070] Such as ...

no. 3 approach

[0077] Next, use Figure 6 Next, a vehicle body reinforcement structure according to a third embodiment of the present invention will be described. Figure 6 Horizontal sectional view for middle use (equivalent to that of the first embodiment figure 1 ) shows a center pillar 40 to which the vehicle body reinforcement structure according to the present embodiment is applied. As shown in the figure, in the center pillar 40, the structure of the second reinforcement reinforcement 42 as the second reinforcement member on the outer side in the vehicle width direction has the same structure as that of the second reinforcement reinforcement 20 ( figure 1 The structure of the part outside in the vehicle width direction in reference) is different. The other structures are the same as those of the first embodiment. Therefore, the same reference numerals are assigned to the same constituent parts as those in the first embodiment, and description thereof will be omitted.

[0078] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com