An electric bicycle performance testing platform

An electric bicycle and test platform technology, which is applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problem of car body loading, unable to quantitatively test the performance of bicycles/light electric motorcycles, and unable to quantitatively simulate the car body Affected by the problems of different resistance states, etc., to achieve the effect of reliable detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention are further described below in conjunction with specific embodiments.

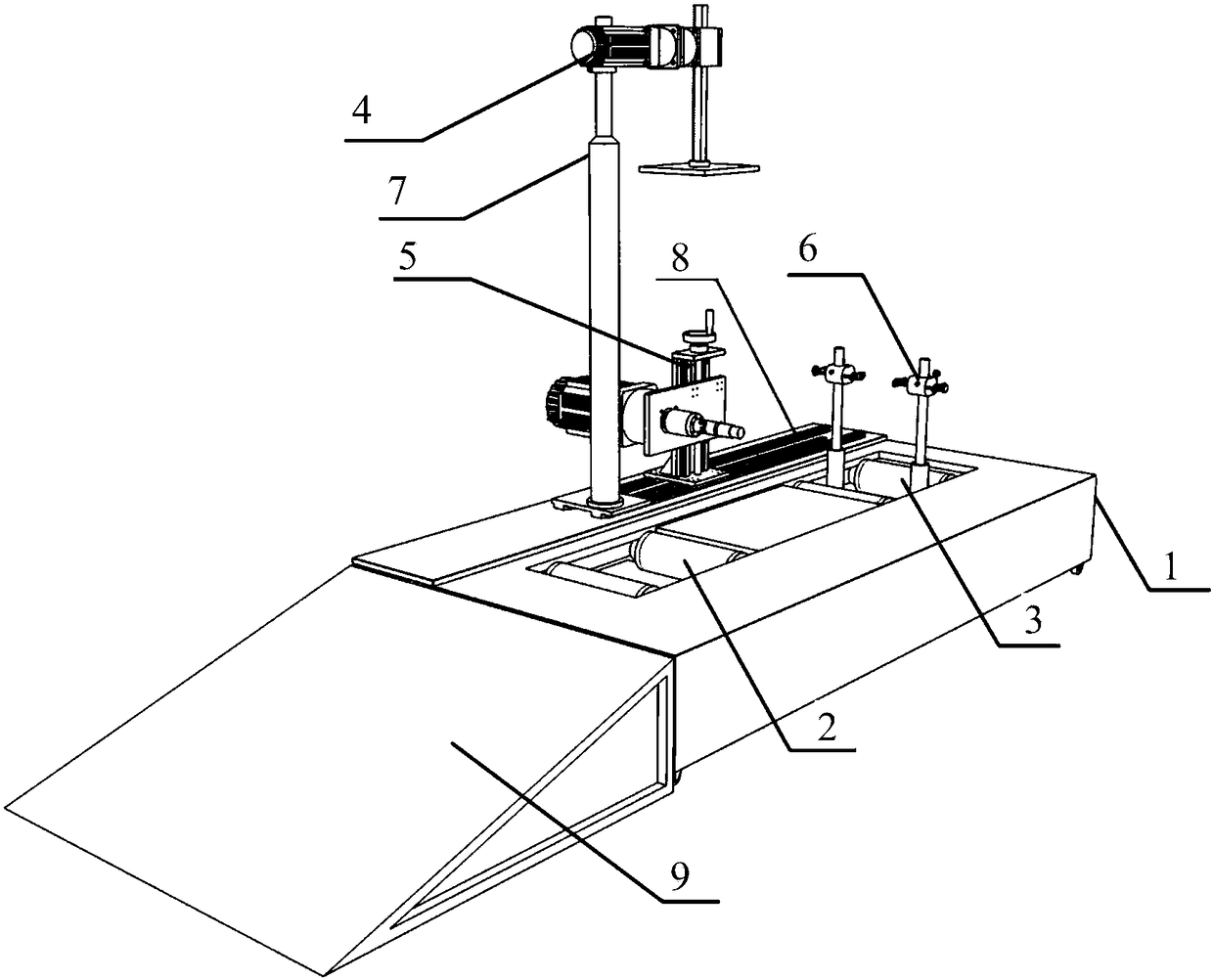

[0025] An electric bicycle performance test platform, see attached figure 1 , including a rear wheel drive device 2 , a front wheel support device 3 , a seat pressing device 4 , a central axle drive device 5 , a front wheel fixing frame 6 , a base frame 10 and a housing 1 .

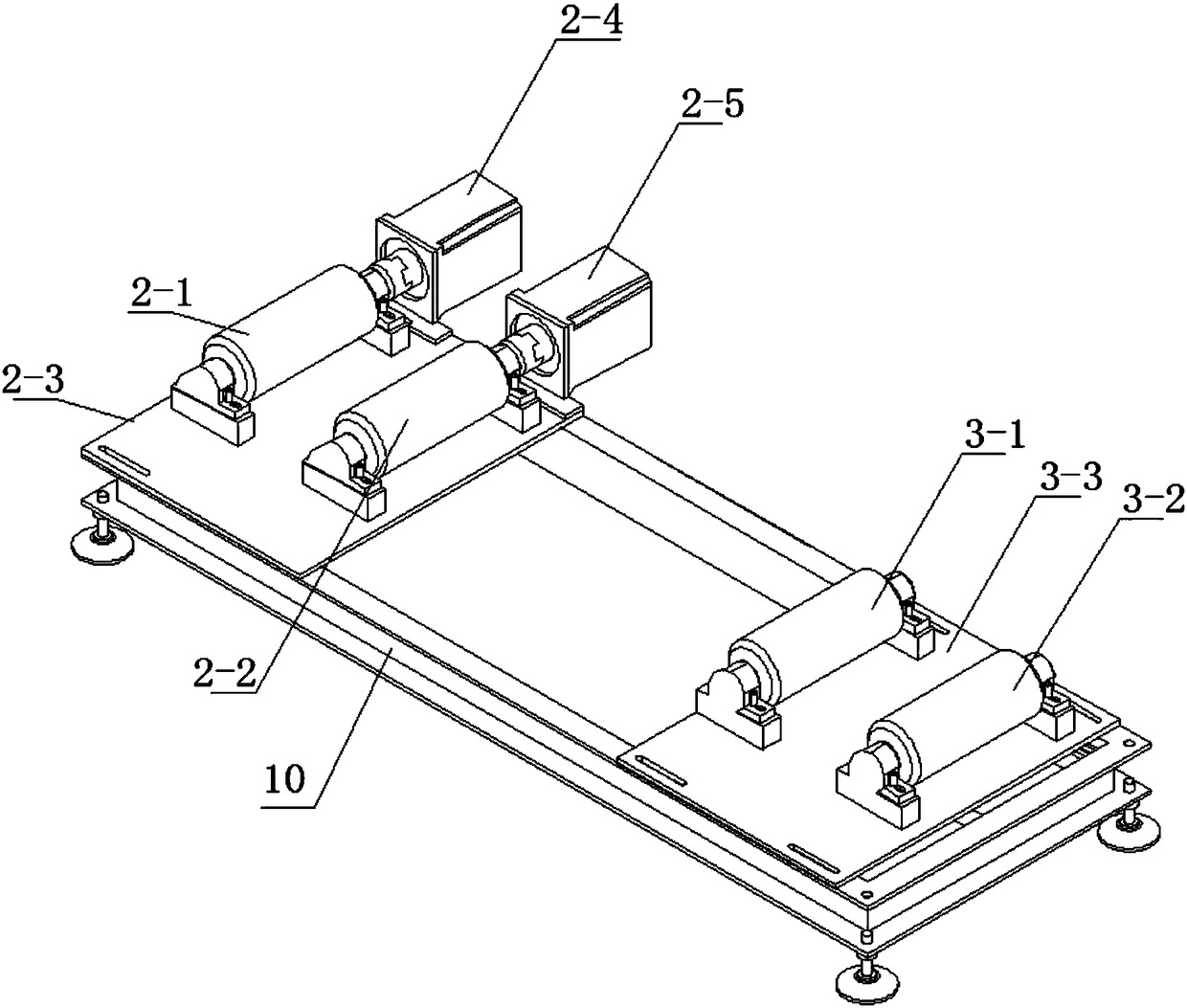

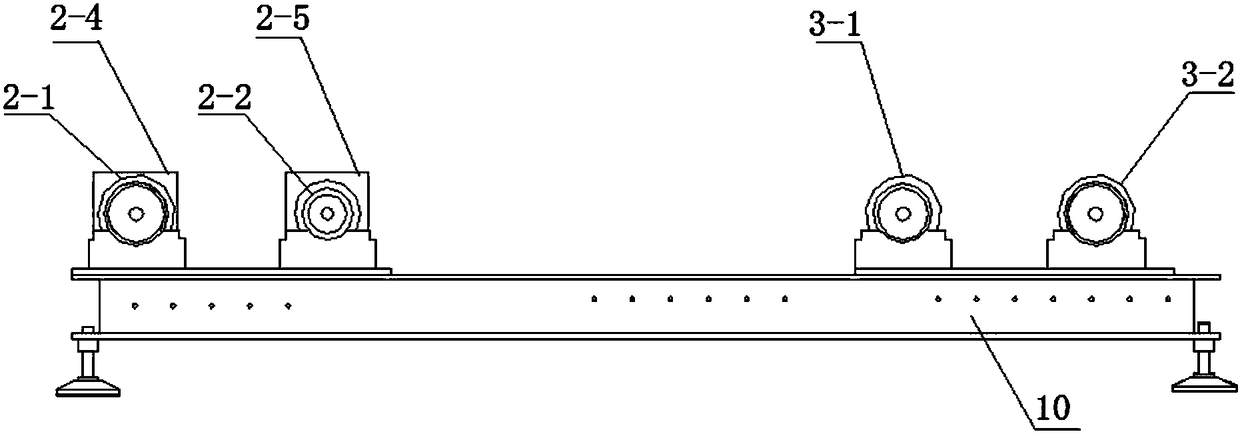

[0026] see attached figure 2 and attached image 3 , the rear wheel drive device 2 includes a first rear axle roller 2-1 and a second rear axle roller 2-2, the first rear axle roller 2-1 and the second rear axle roller 2-2 are parallel to each other through the bearing seat It is arranged on the first flat plate 2-3, and the first flat plate 2-3 is horizontally fixed on the second half of the base frame 10; the first rear axle roller 2-1 is connected with the first motor 2-4; The second rear axle roller 2-2 is connected with the second motor 2-5;

[0027] The front wheel sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com