Patents

Literature

36results about How to "Realize Quantitative Testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

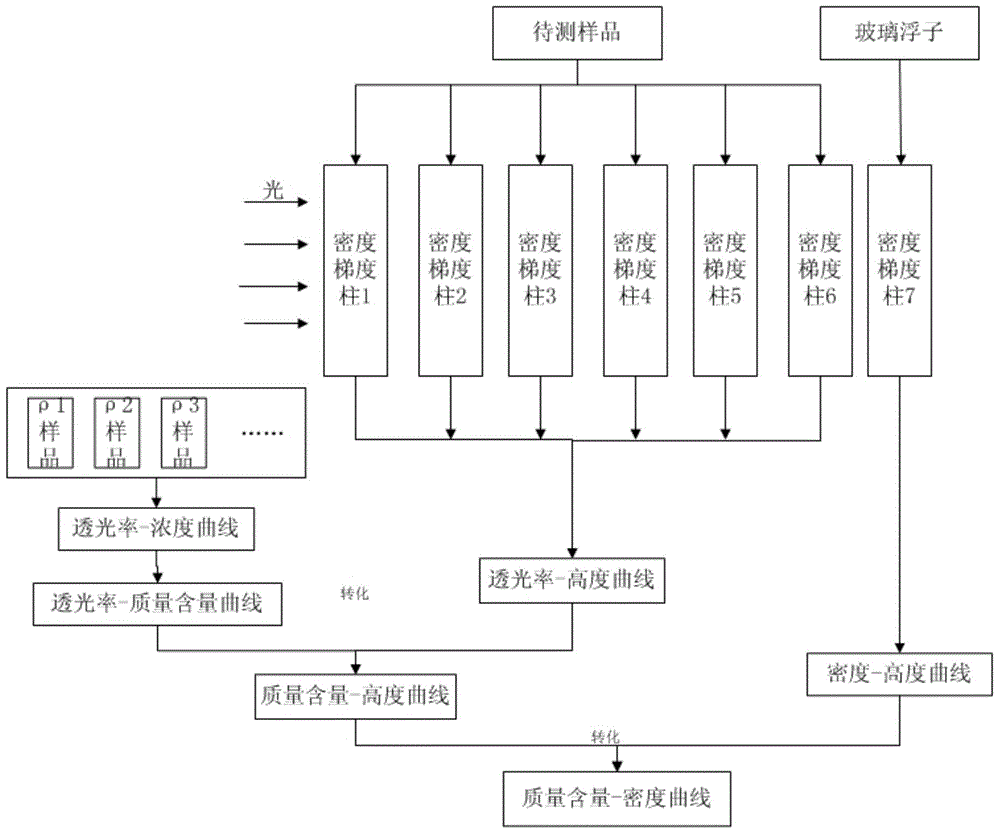

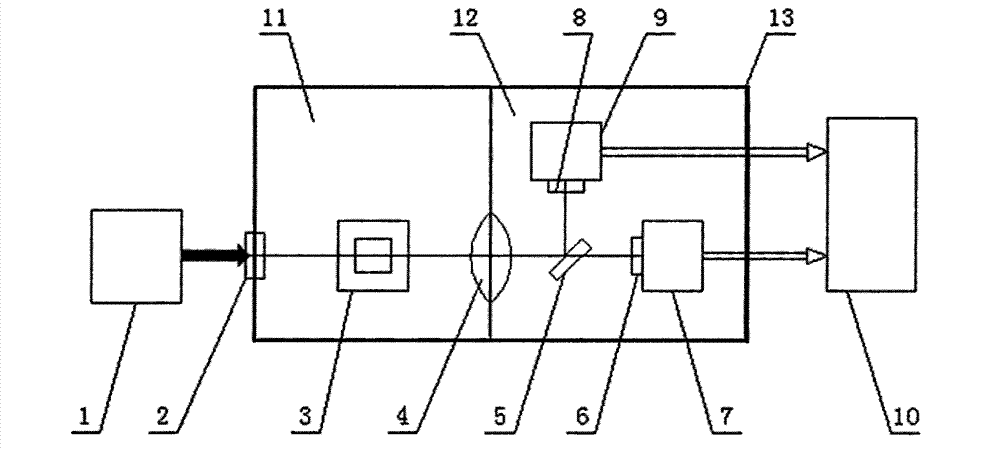

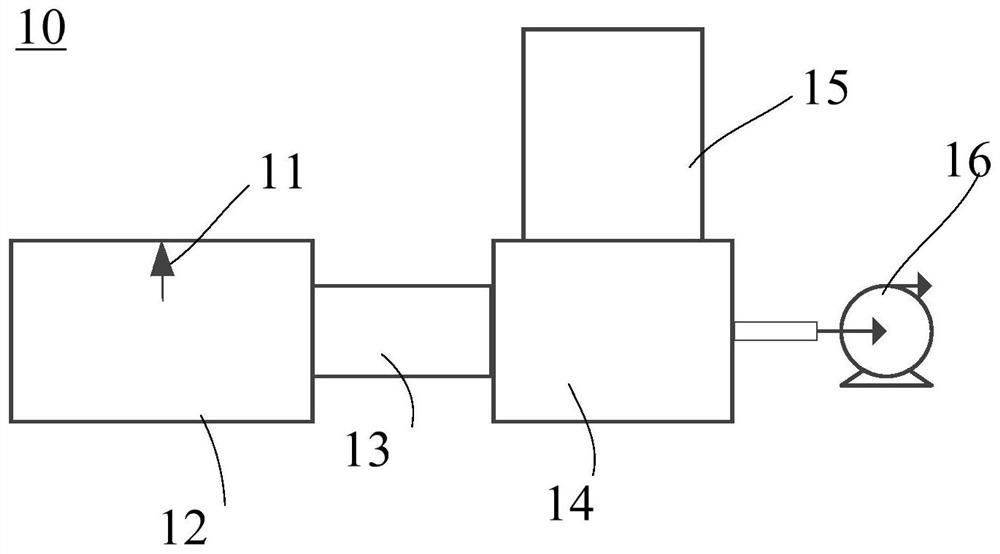

Double-channel second-order nonlinear optical test system

ActiveCN102192899ARealize the test of nonlinear optical performance at different wavelengthsSimple structureAnalysis by material excitationResponse sensitivitySingle crystal

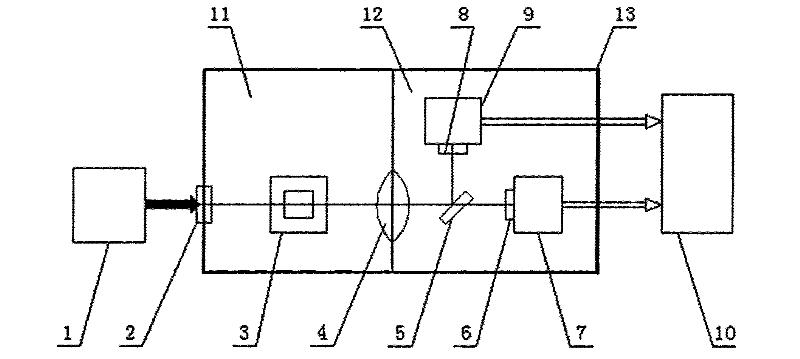

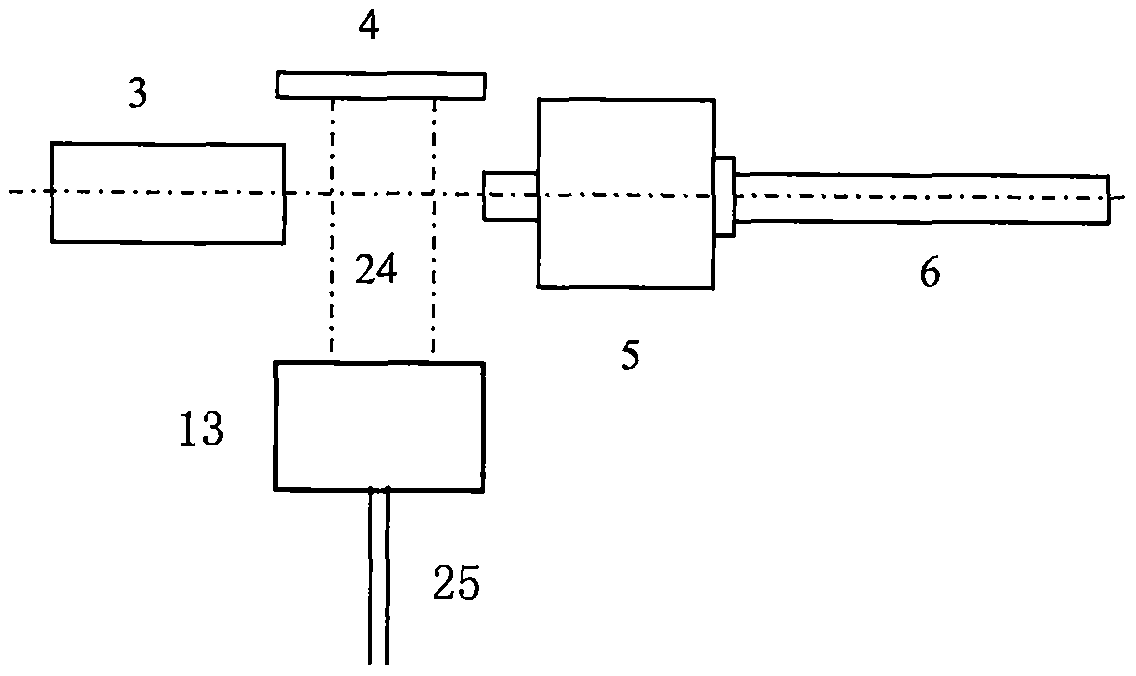

The invention discloses a double-channel second-order nonlinear optical test system which is used for testing the second-order nonlinear optical effects of materials. The system comprises a laser light source, a photic sheet, a sample rack, a focusing lens, a spectroscope, a first optical filter, a first photomultiplier, a second optical filter, a second photomultiplier, a signal receiving analyzer and a photophobic box. According to the intensities of frequency-doubled lasers and non-frequency-doubled lasers contained in optical signals generated by exciting samples by lasers and the relative intensity relationship thereof, the laser-induced optical signal lights after respectively passing through the first optical filter and the second optical filter are subjected to two-channel exploration by virtue of the first and second photomultipliers, then through carrying out comparison and analysis on signals generated through two-channel exploration, the qualitative and quantitative test on the second-order nonlinear optical effects of powder-monocrystal containing samples is realized. The double-channel second-order nonlinear optical test system is simple in structure, light, practical, and easy to operate, has the advantages of wide waveband application range, high response sensitivity, and the like; and by using the system, the qualitative and quantitative test on the second-order nonlinear optical effects of sample materials can be effectively realized, therefore, the system has the advantages of broad application prospect and high application value.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

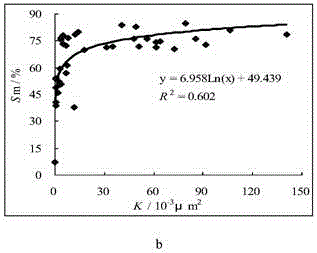

Method of quantitatively evaluating mobile fluid of ultra-deep reservoir stratum and application thereof

InactiveCN106483057AImplement featuresRealize Quantitative TestingAnalysis using nuclear magnetic resonancePermeability/surface area analysisFluid saturationSoil science

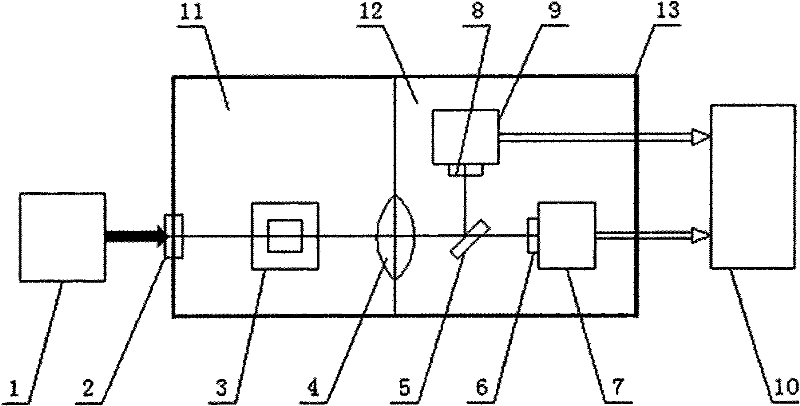

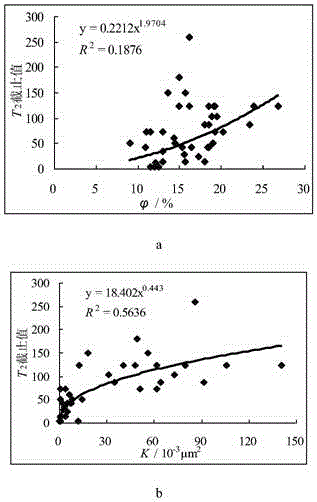

The invention discloses a method of quantitatively evaluating mobile fluid of an ultra-deep reservoir stratum and application thereof, and relates to the field of reservoir stratum evaluation. To solve the problems that no special testing method exists for the mobile fluid of the ultra-deep reservoir stratum, and a conventional testing method has large errors, the method of quantitatively evaluating the mobile fluid of the ultra-deep reservoir stratum is provided. The method of quantitatively evaluating the mobile fluid of the ultra-deep reservoir stratum includes the steps that a sample is processed to keep the temperature and pressure conditions of the sample in the sampling stratum, the T2 spectrum is obtained, and the relation map between core mobile fluid saturation and related core parameters and physical properties is obtained. Porosity of the mobile fluid can be obtained and synthesizes reservoir stratum reserving capacity and fluid deposit characteristic information, the mobile fluid of the ultra-deep reservoir stratum can be quantitatively evaluated, and fluid-solid coupling characteristics of the ultra-deep reservoir stratum can be reflected more accurately.

Owner:XI'AN PETROLEUM UNIVERSITY

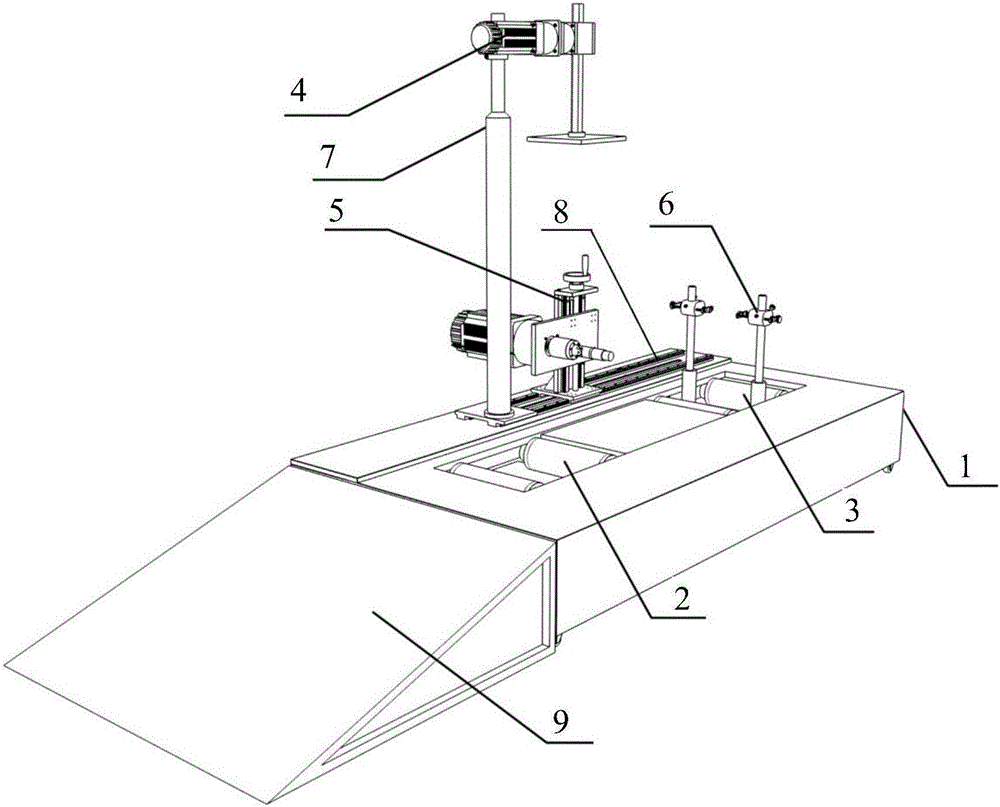

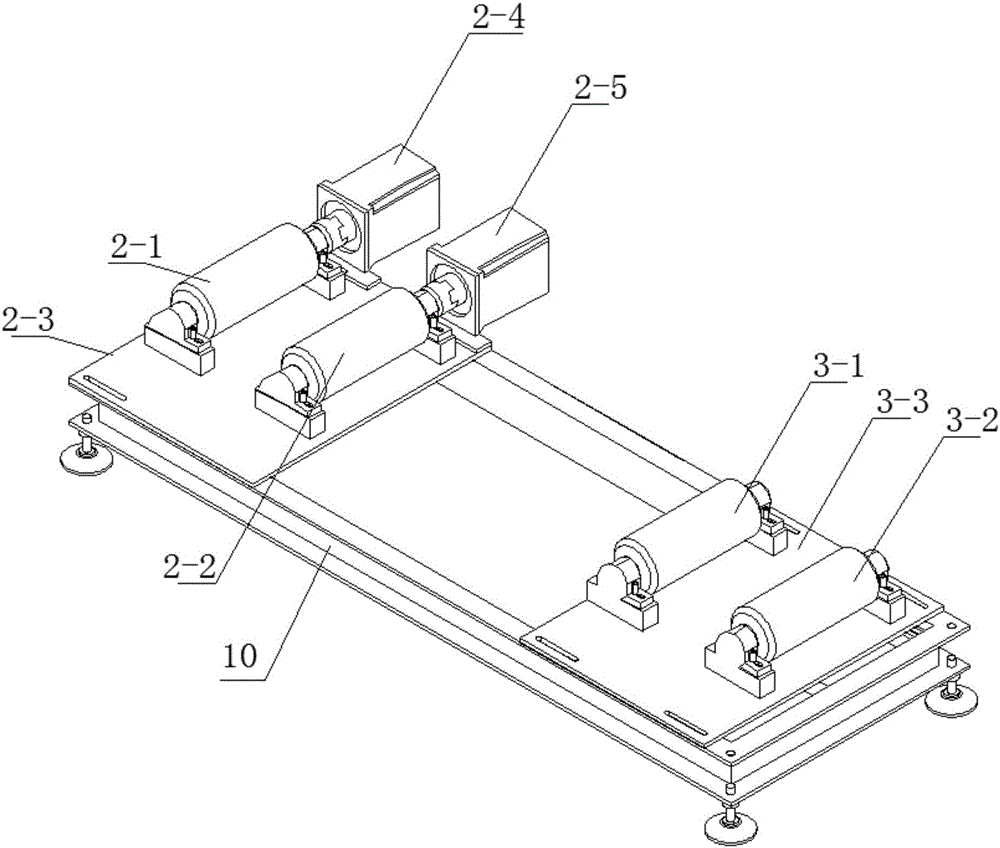

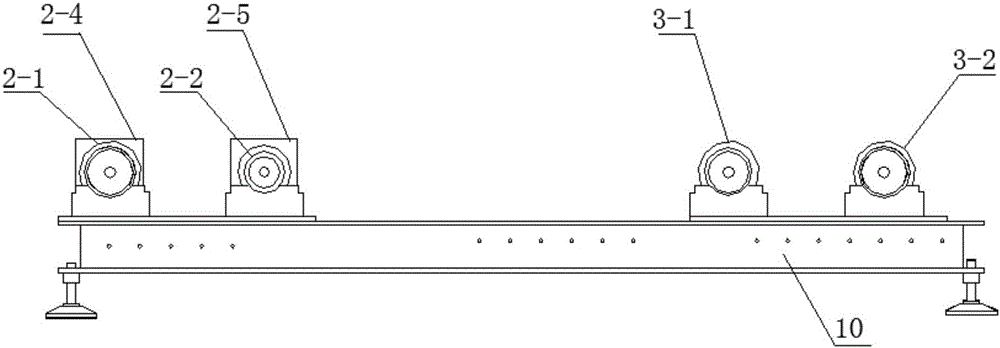

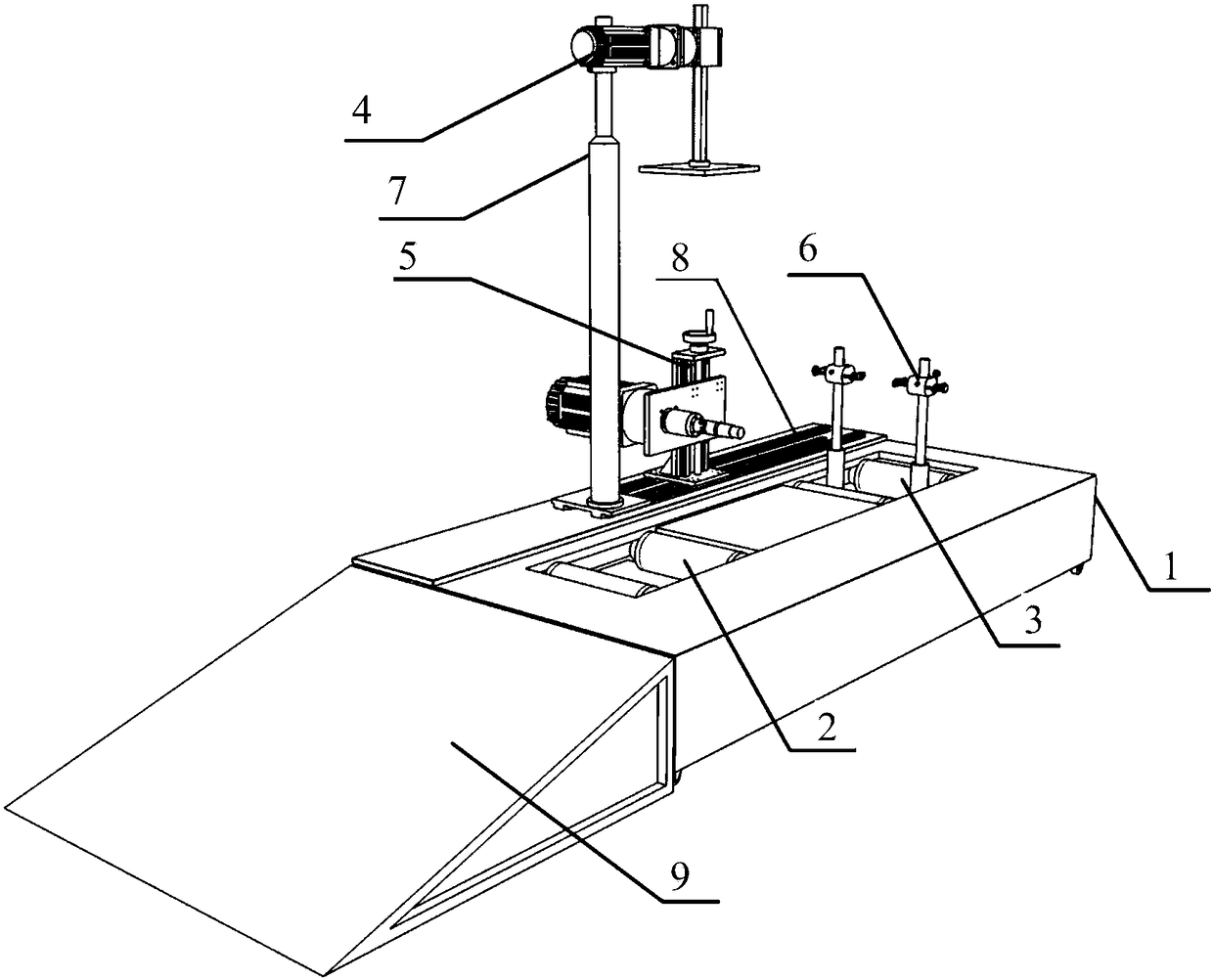

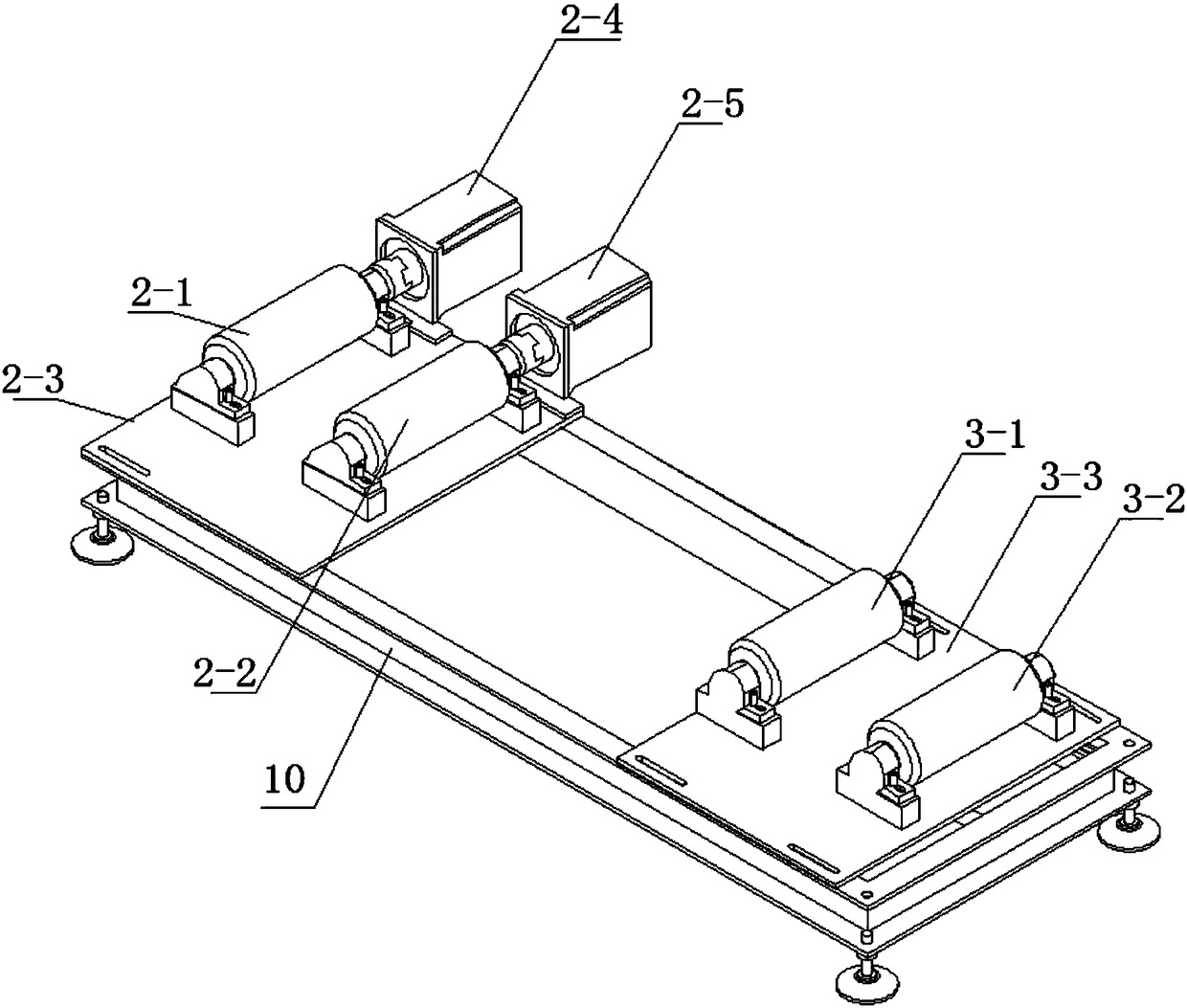

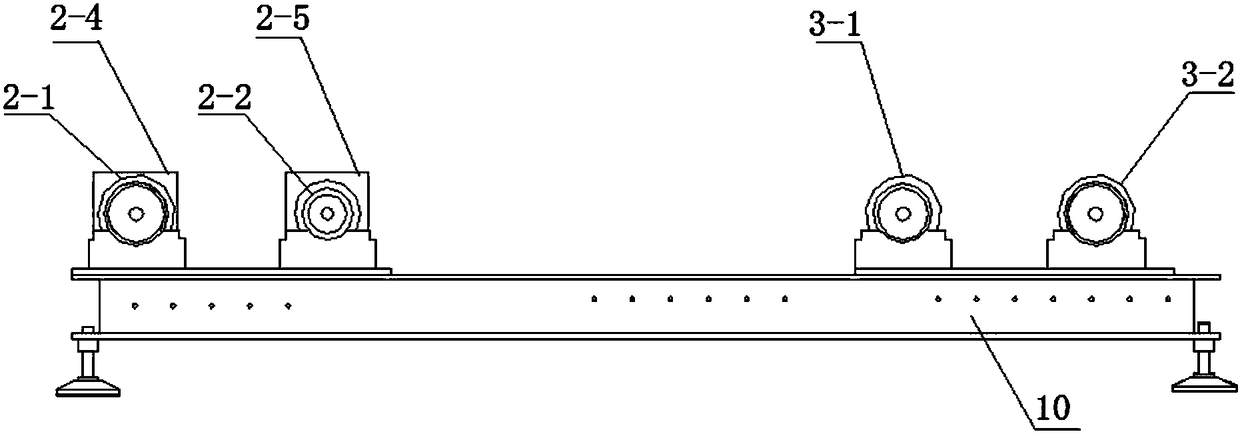

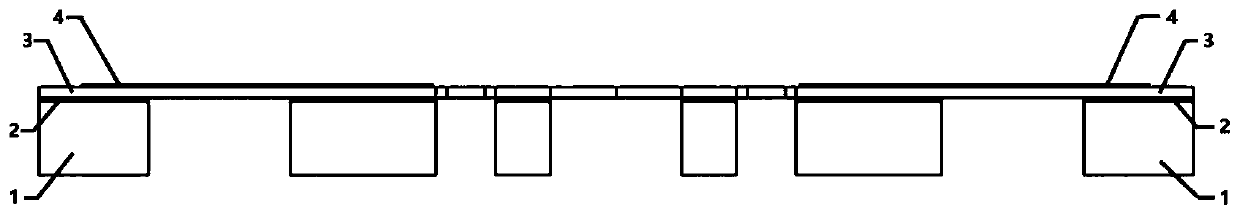

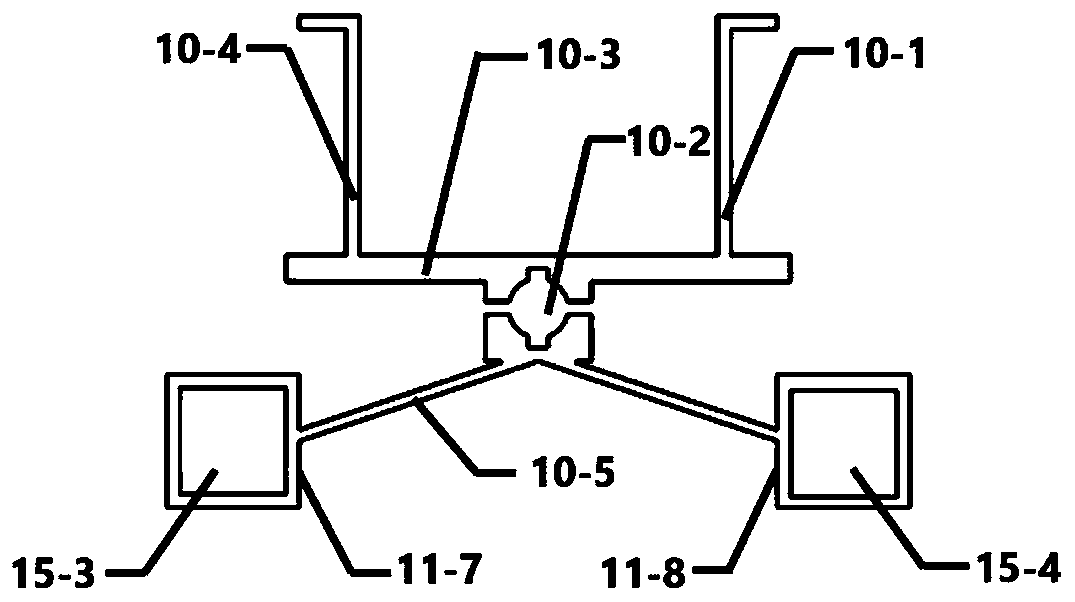

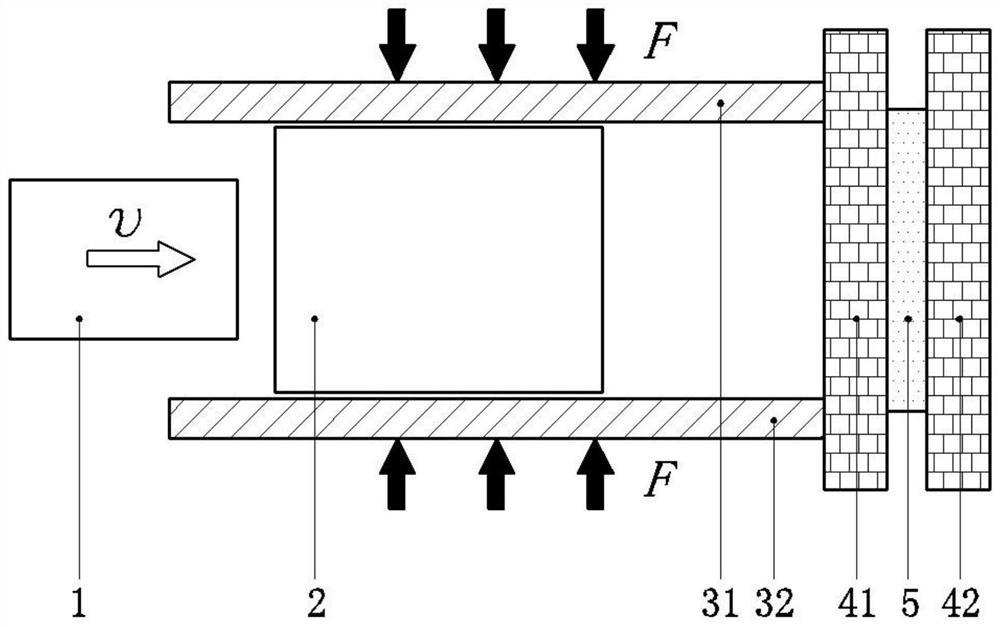

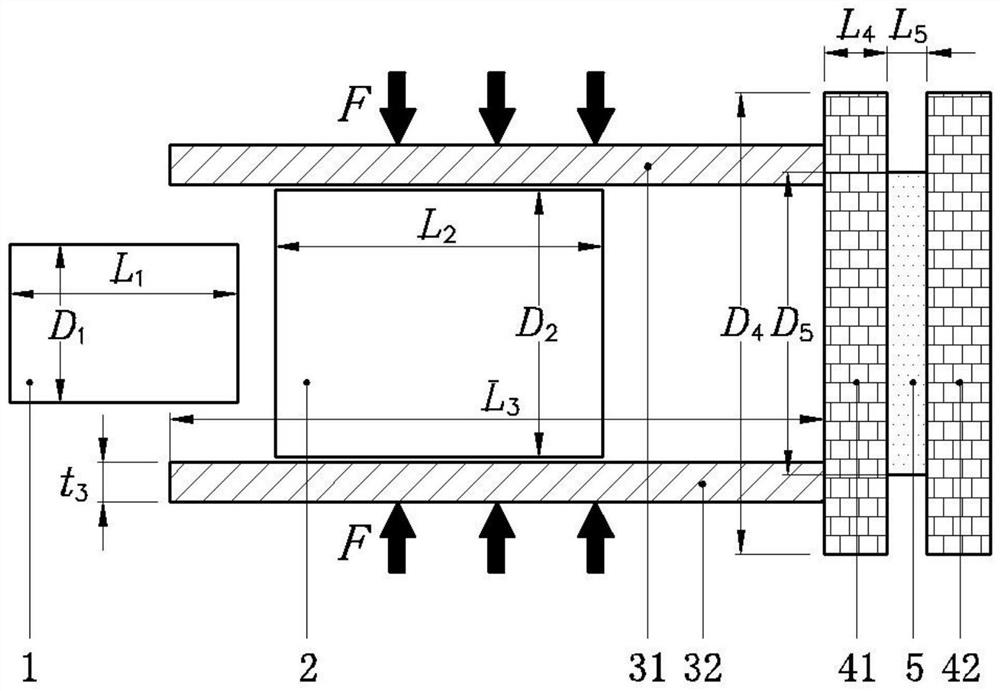

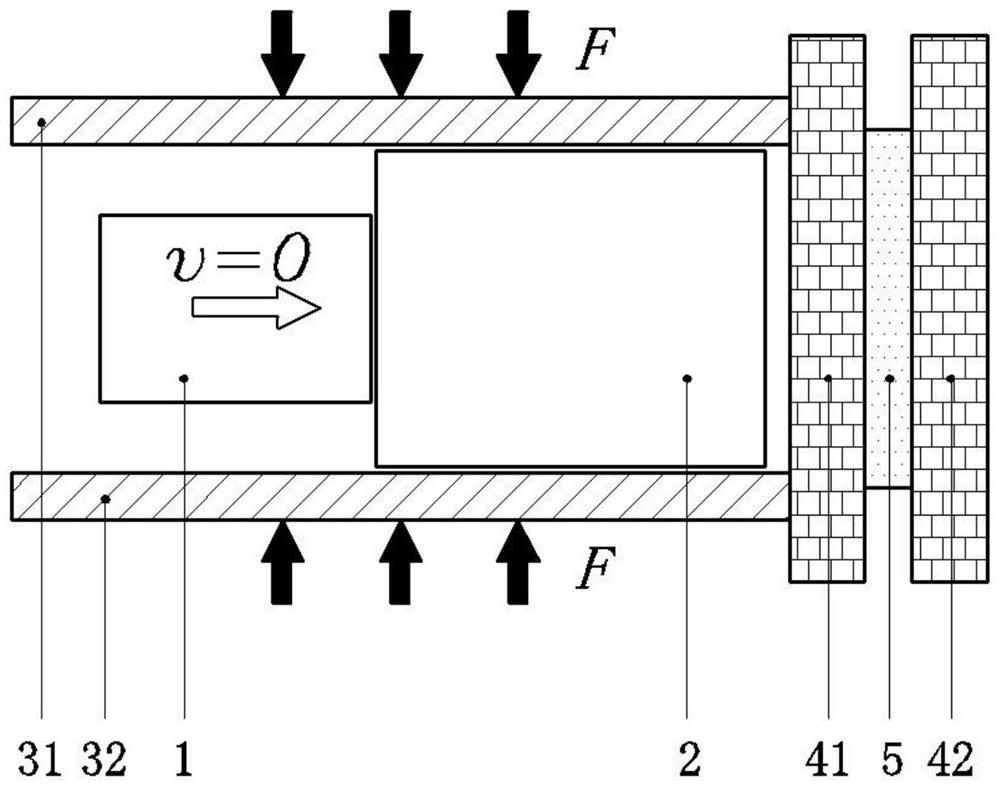

Electric bicycle performance test platform

ActiveCN106053096AReliable test resultsWith friction resistance compensation functionVehicle testingElectric vehicleWheel drive

The invention discloses an electric bicycle performance test platform comprising a rear wheel driving device and a vehicle seat compressing device. The wheel driving device comprises a first rear axle roller and a second rear axle roller. The first rear axle roller and the second rear axle roller are fixed in a mutually parallel way through bearing pedestals. The first rear axle roller is connected with a first motor. The second rear axle roller is connected with a second motor. The rear wheel of a tested vehicle body is arranged in the two rear axle rollers of the rear wheel driving device. The vehicle seat compressing device is used for loading compressing force for the tested vehicle body so as to simulate vehicle-mounted weight. The second motor and the second rear axle roller load positive torque to the rear wheel of the vehicle body to apply push force and the vehicle wheel is enabled to be in the critical operation state so as to compensate frictional force of the test platform and frictional resistance between the vehicle wheel of the electric vehicle and the rollers of the test platform. The first motor and the first rear axle roller load opposite torque to the rear wheel to apply resistance so as to quantitatively simulate the resistance in driving of the electric vehicle.

Owner:天津铭志成科技有限责任公司

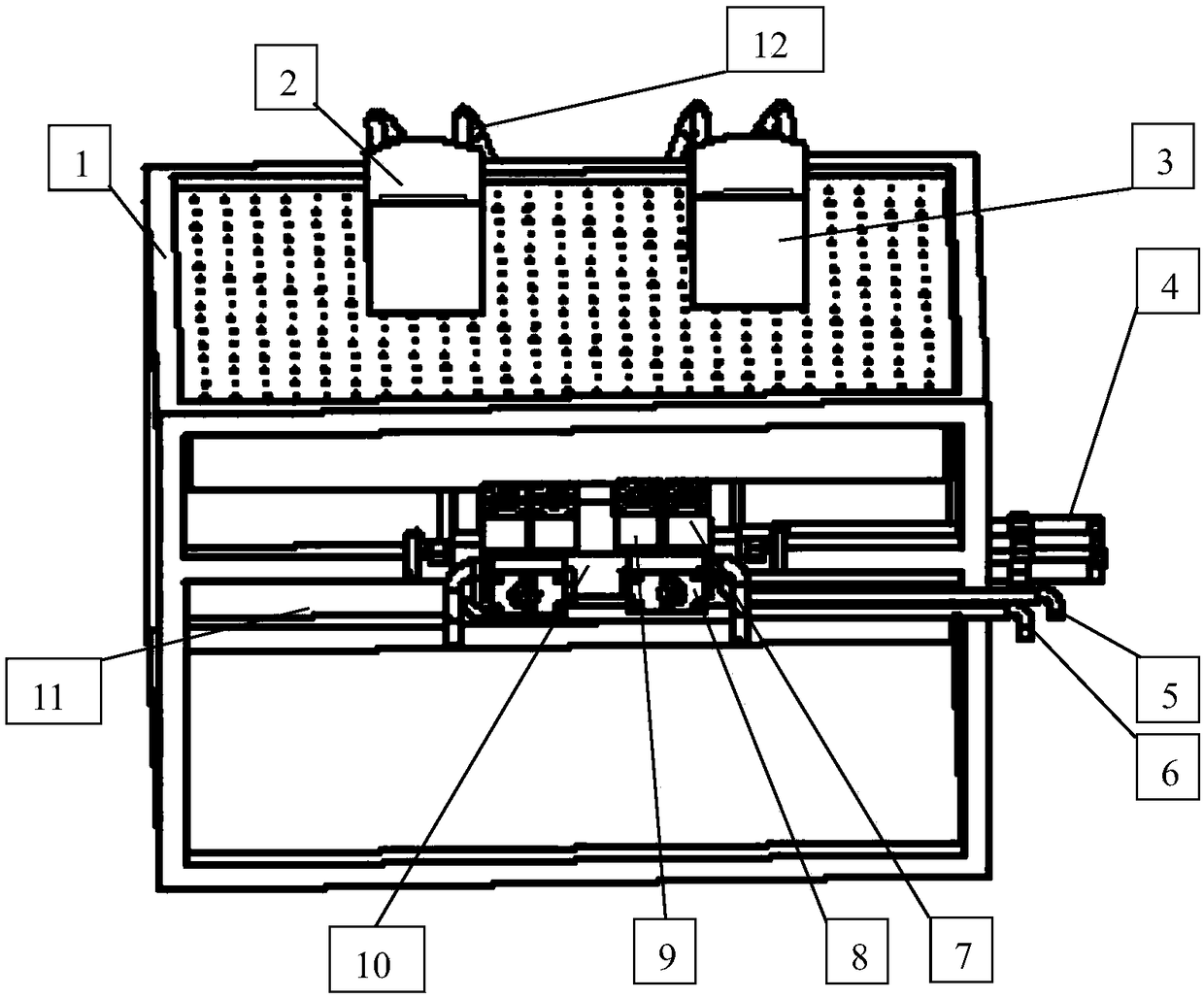

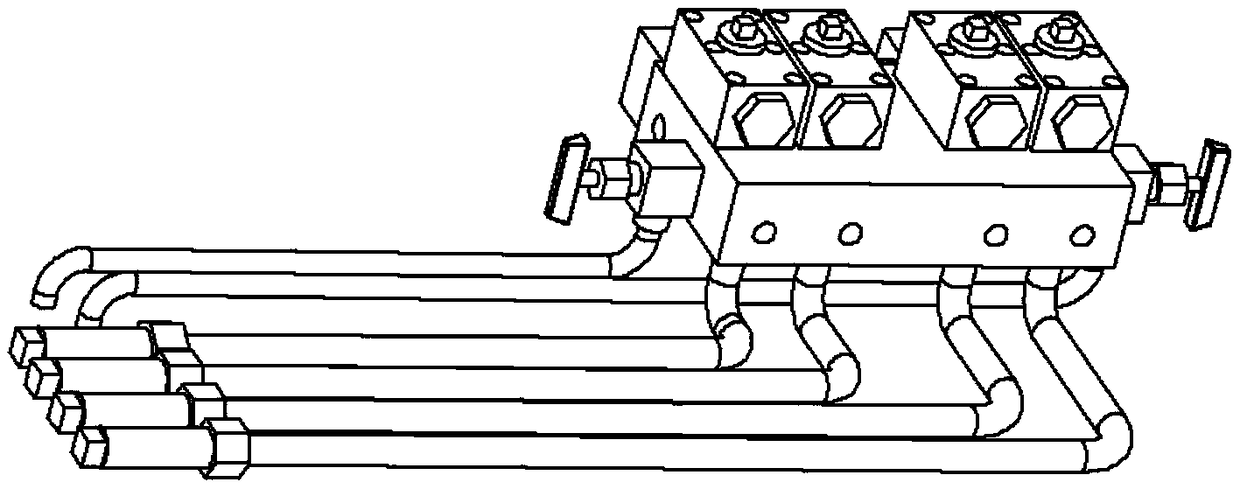

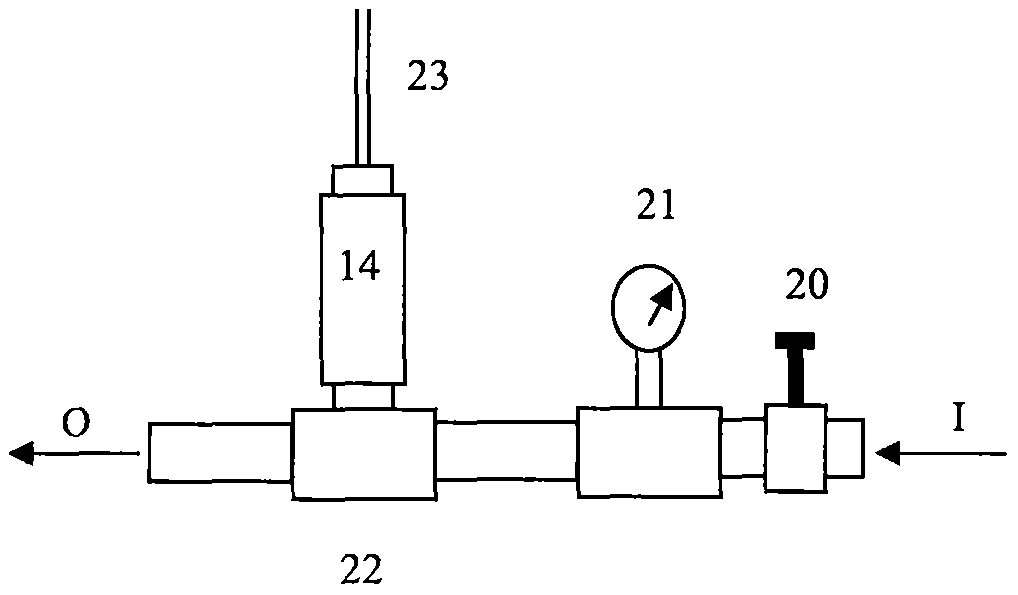

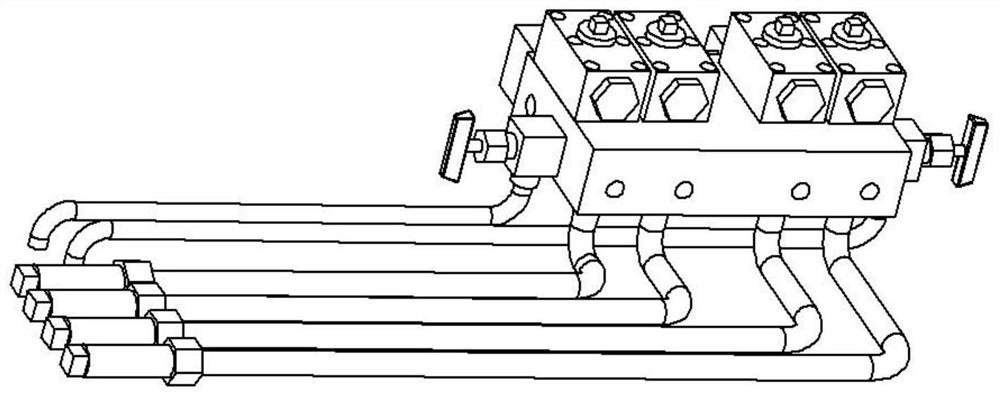

Atomizing block measuring apparatus

InactiveCN101373169ARealize Quantitative TestingStructural/machines measurementPressure difference measurement between multiple valvesEngineeringPressure sensor

The invention relates to a device for determining spraying blockage, which comprises a pressure pump used for extracting and pressurizing liquid in a medical box, a first pressure sensor connected with the pressure pump and used for determining the pressure of the liquid, a filter connected with the first pressure sensor and used for filtering the liquid, a second pressure sensor connected with the filter and used for determining the pressure of the liquid after being filtered, a first switch connected with the second pressure sensor, and a controller respectively connected with the pressure pump, the first pressure sensor, the second pressure sensor and the first switch and used for turning off the first switch after determining that the filter is blocked. The device for determining spraying blockage determines the blockage of the filter during a repeated and cyclic spraying test, indicates blockage alarm, records the pressure during the spraying process, and realizes quantitative test for blockage during the spraying of different chemical pesticides.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

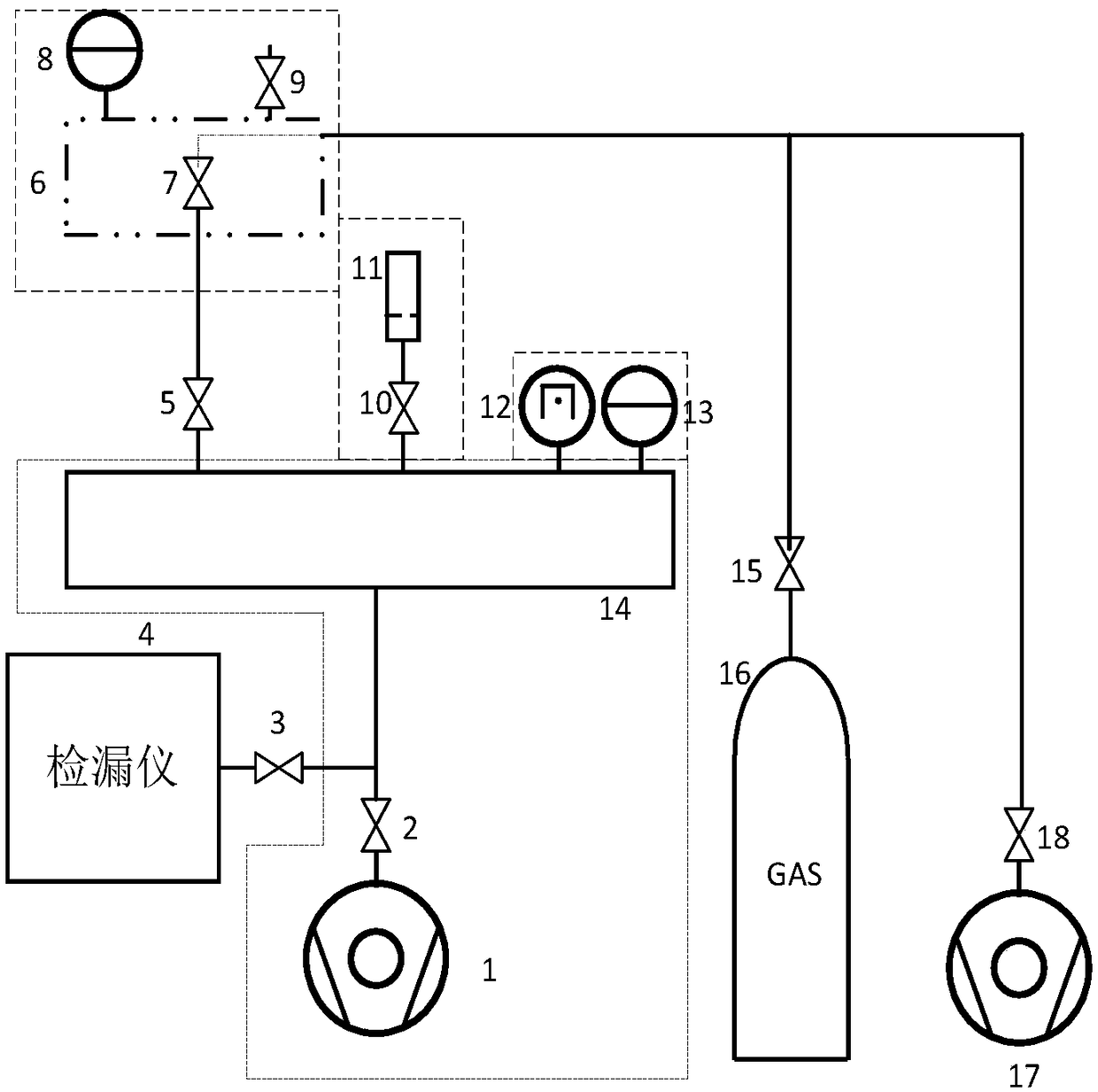

Vacuum sealed valve leakage rate test system and method

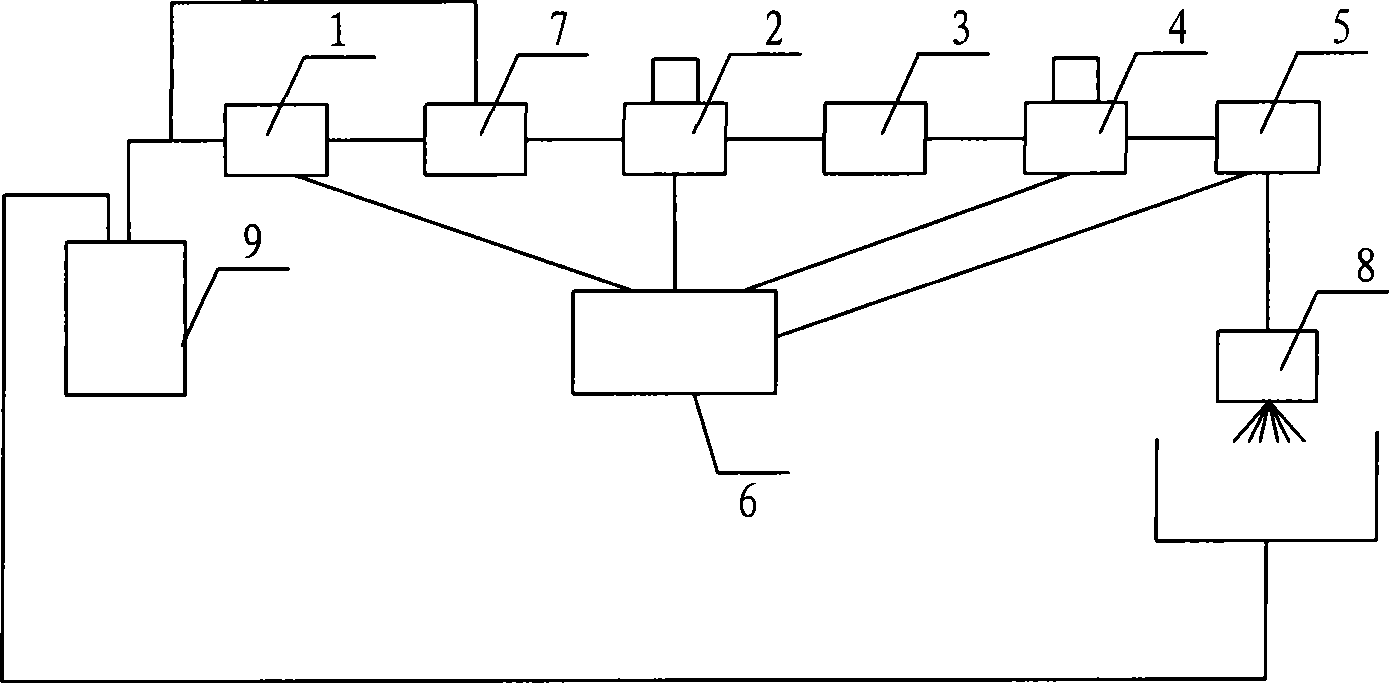

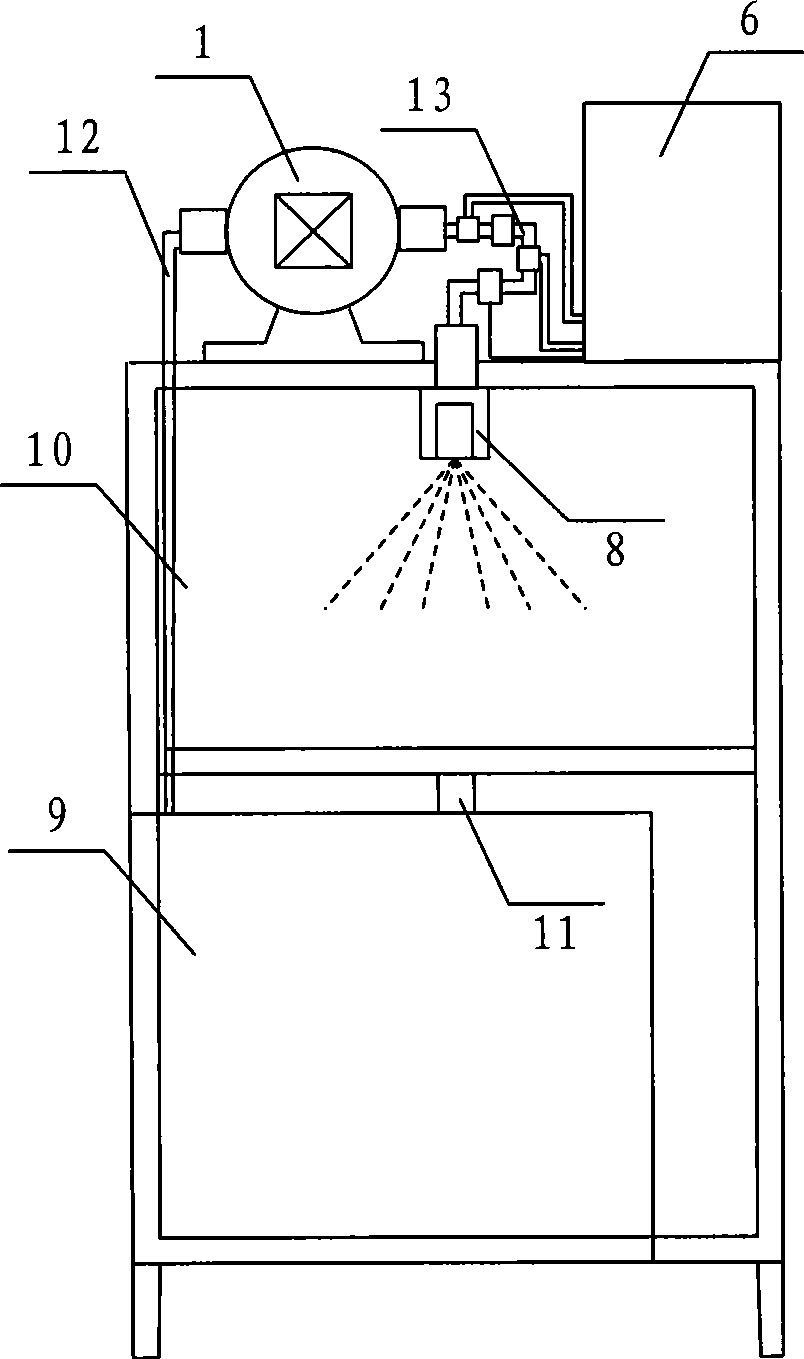

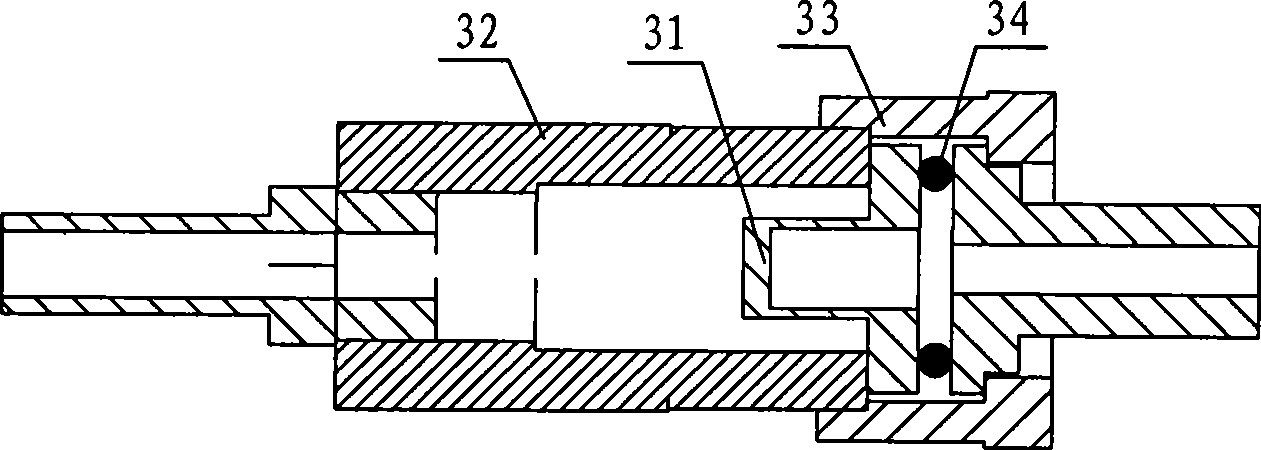

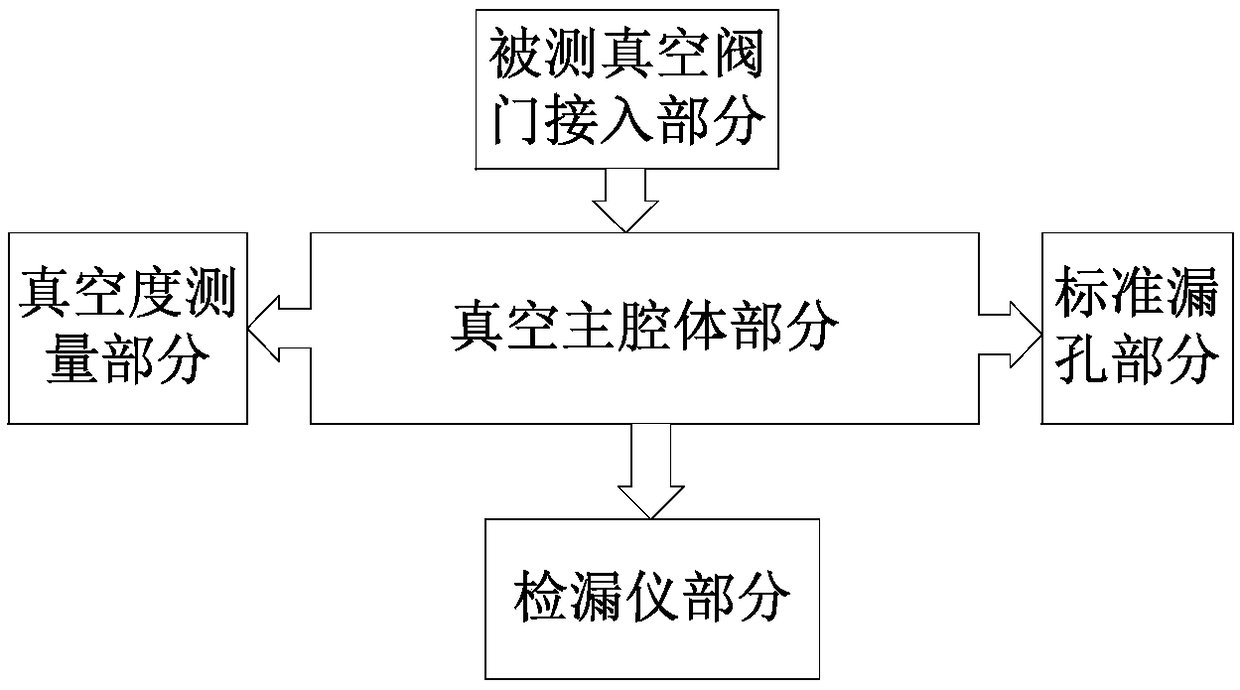

InactiveCN109269742AImprove measurement uncertaintyRealize Quantitative TestingMeasurement of fluid loss/gain rateEngineeringVacuum pump

The invention provides a vacuum sealed valve leakage rate test system and method. The system consists of a first vacuum pump set and a second vacuum pump set, a leak detector, a vacuum chamber, a vacuum valve test cover, a pressure gauge, a standard leak hole, vacuum gauges, a gas source, and a first vacuum valve, a second vacuum valve, a third vacuum valve, a fourth vacuum valve, a fifth vacuum valve, a sixth vacuum valve, and a seventh vacuum valve, wherein the first vacuum pump set is connected to the vacuum chamber through the first vacuum valve, and the leak detector is connected to the vacuum chamber through the second vacuum valve. The vacuum chamber is connected to one ends of the vacuum gauges, the third vacuum valve and the fifth vacuum valve respectively. The other end of the fifth vacuum valve is connected to the standard leak hole. A tested vacuum valve is installed in the vacuum valve test cover, one end of the tested vacuum valve is connected to the other end of the third vacuum valve, and the other end is respectively connected to the fourth vacuum valve and the pressure gauge. The gas source is in connection with the vacuum valve test cover through the sixth vacuumvalve, and the second vacuum pump set is in connection with the vacuum valve test cover through the seventh vacuum valve respectively. The system and method provided by the invention realize quantitative test of the vacuum valve local leakage rate and total leakage rate, and greatly improves the measurement uncertainty of vacuum sealed valve leakage rate.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

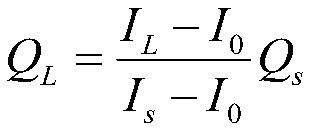

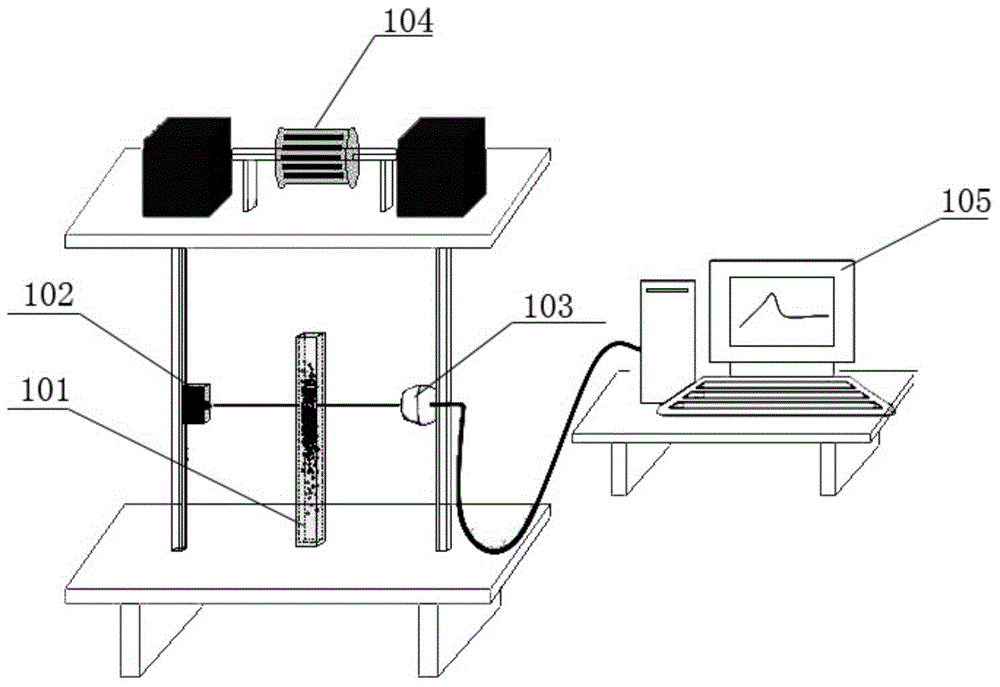

Method for testing continuous distribution of crystal density based on density gradient light transmittance method

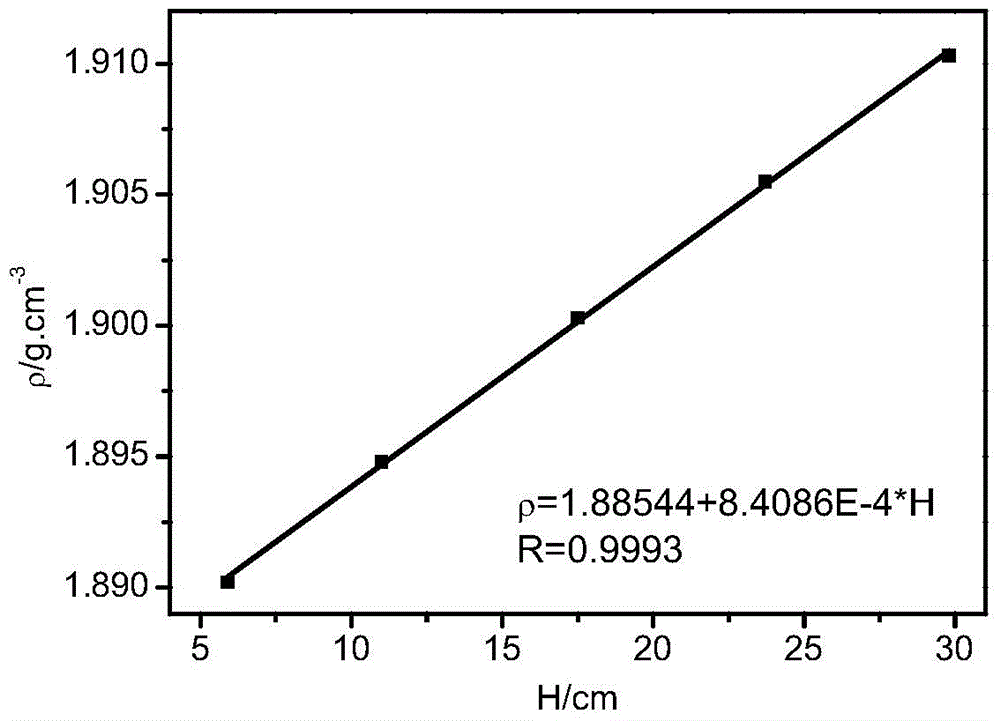

ActiveCN104089851ARealize Quantitative TestingEasy to operateSpecific gravity measurementData acquisitionDensity based

The invention discloses a method for quickly measuring the continuous distribution of crystal density of an energetic material. Crystal samples are naturally settled down and stabilized at different positions of a density gradient tube according to a density difference by using the density gradient tube, and the liquid densities of the crystal samples at different heights are calibrated and corrected through standard density floaters; then a light source generator and a light source detector which are mounted on two sides of the density gradient tube perform synchronous up-and-down scanning and data acquisition; a relation curve between the light transmittance and the height is calculated according to the light intensity differences of different heights and different regions, so that a continuous density distribution curve of the crystal samples is accurately calculated. Therefore, the density distribution situations of different crystal samples are judged. The method disclosed by the invention is used for quickly measuring the continuous distribution of the crystal density of the similar energetic materials, and the quantity of the samples under all density gradients is quantitatively expressed; the quantitative test on the density distribution of crystal particles is realized.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

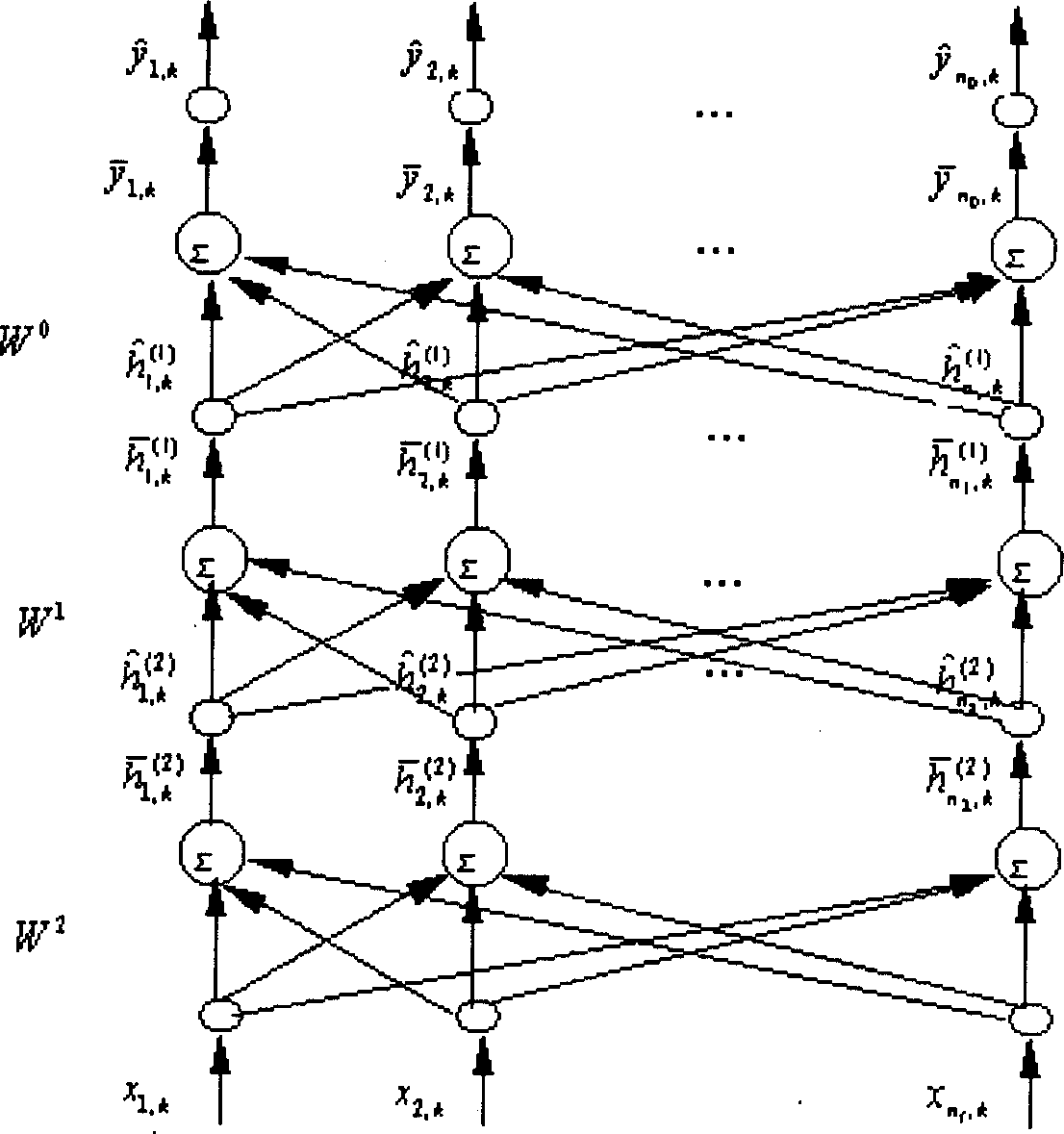

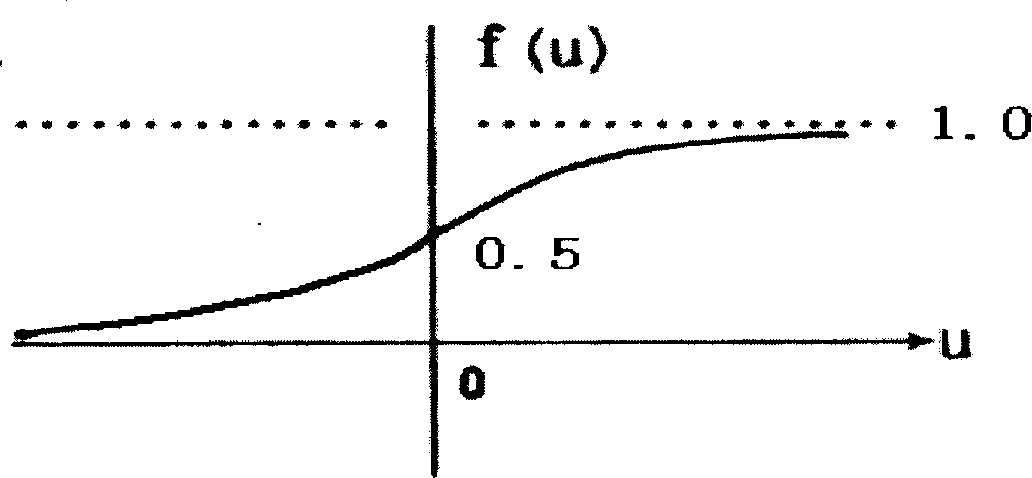

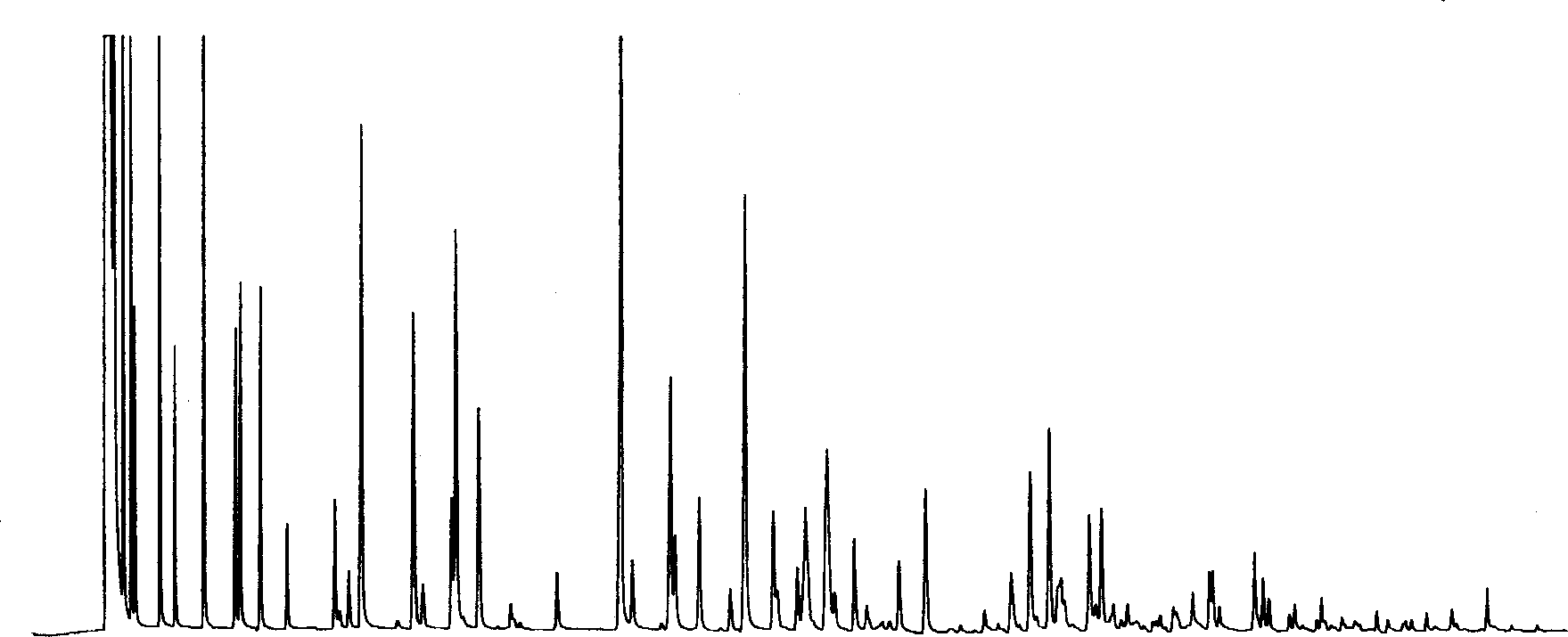

Geochemical method for testing and dynamically monitoring gas storage separate layer production capability of natural gas well

InactiveCN1804613ATest results are accurate and reliableDoes not affect productionComponent separationGeological measurementsWellheadFingerprint

The invention relates to a collecting natural gas reserve air layered yield-power determination and dynamically monitoring geochemistry method. It comprises the following steps: 1) extracting each layer natural gas of the gas recovery well, choosing and computing to obtain each reserve air layered natural gas characteristic hydrocarbon finger mark parameter; 2) extracting each layer natural gas of the gas recovery well, forming analog mixed gas sample by different mixing model and separately doing chromatographic finger mark analysis to obtain different mixing ratio of each reserve air layered natural gas and the chemistry model parameter of the characteristic hydrocarbon finger mark parameters; 3) adopting non-linear artificial nerve network intelligence learning algorithm to establish mathematical model and measuring model plate; 4) collecting the gas recovery sample to do chromatographic finger mark analysis to obtain the corresponding characteristic hydrocarbon finger mark data; 5) computing to obtain the yield-power contribution of the gas recovery each reserve air layered natural gas.

Owner:DAQING OILFIELD CO LTD

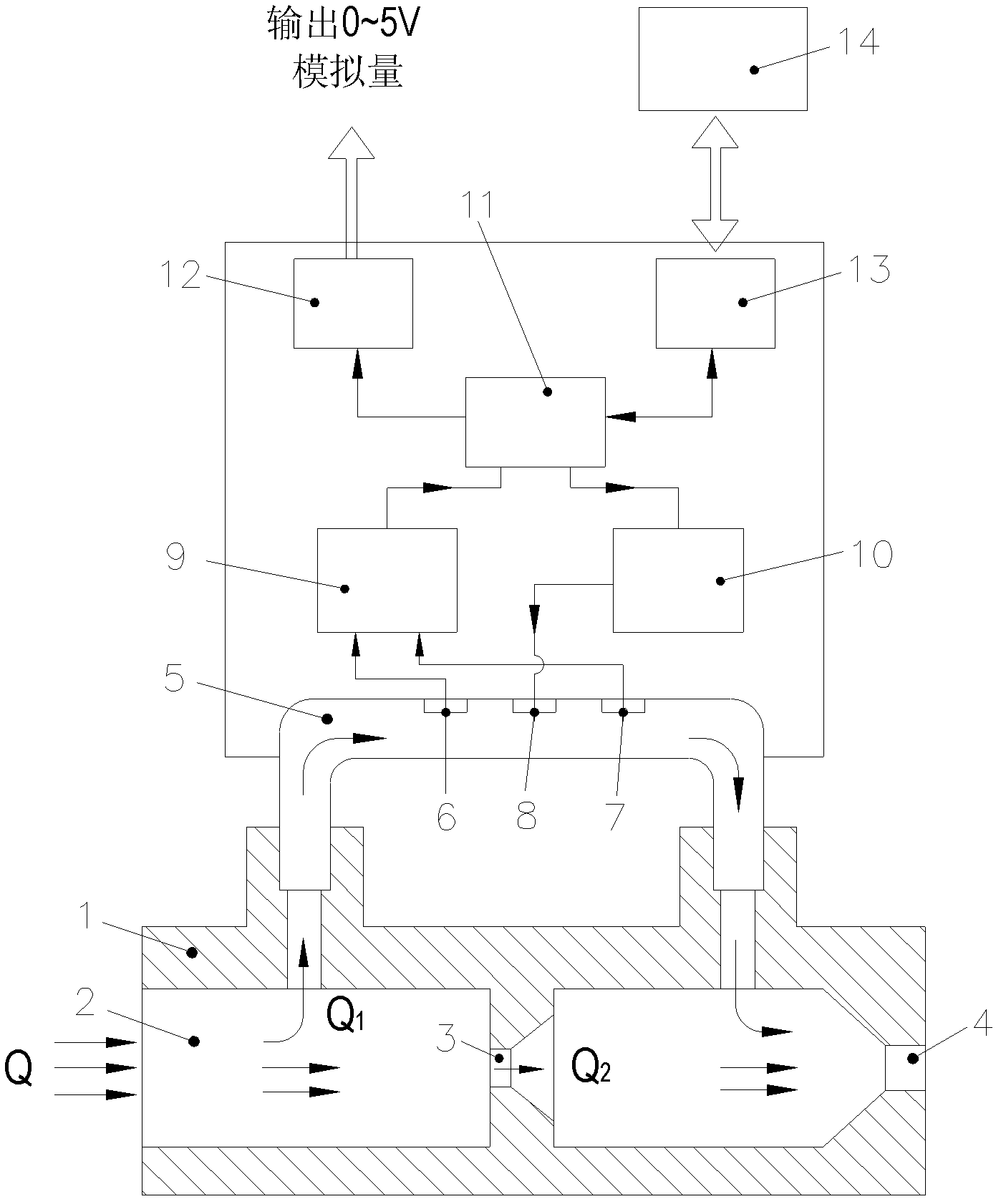

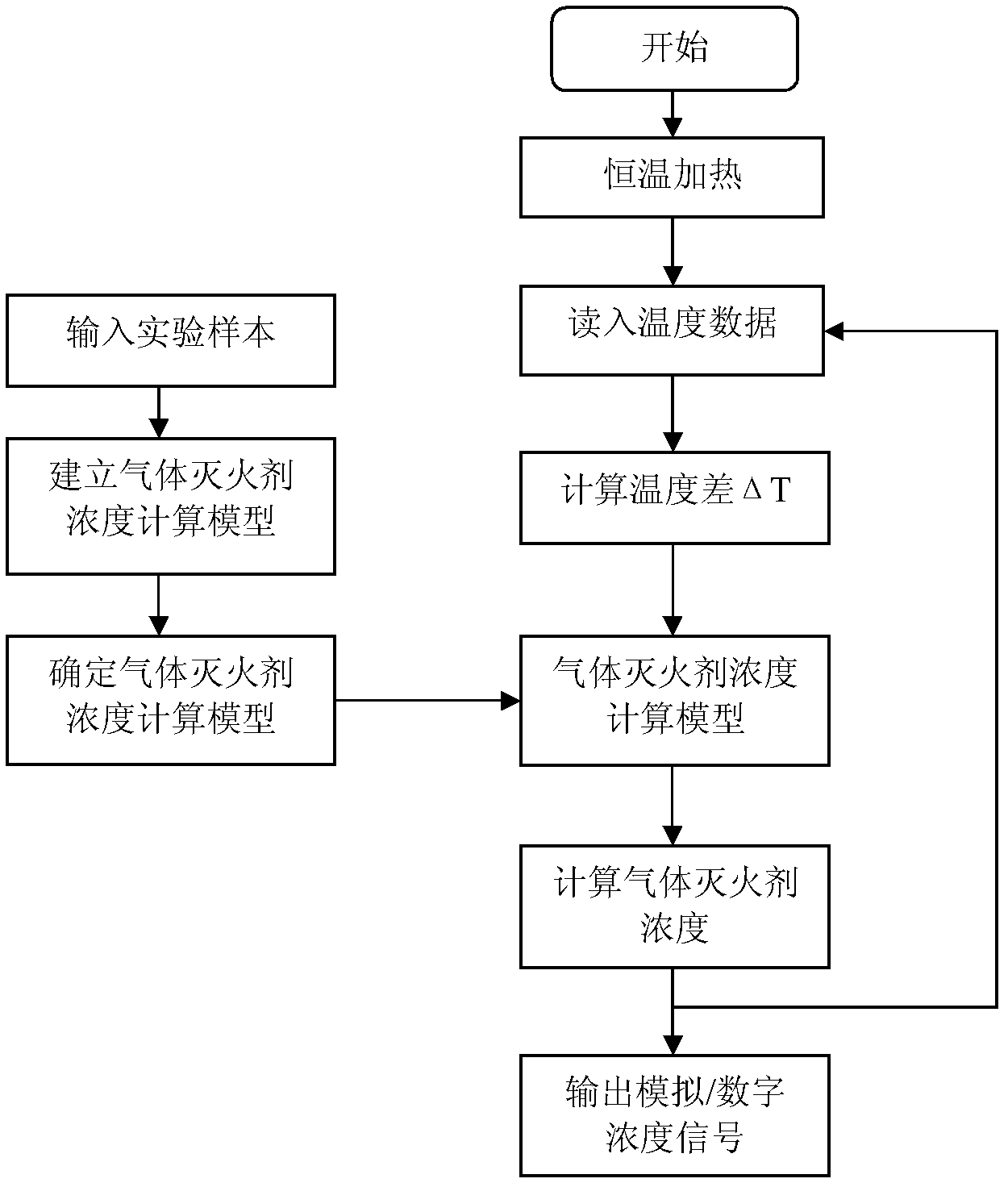

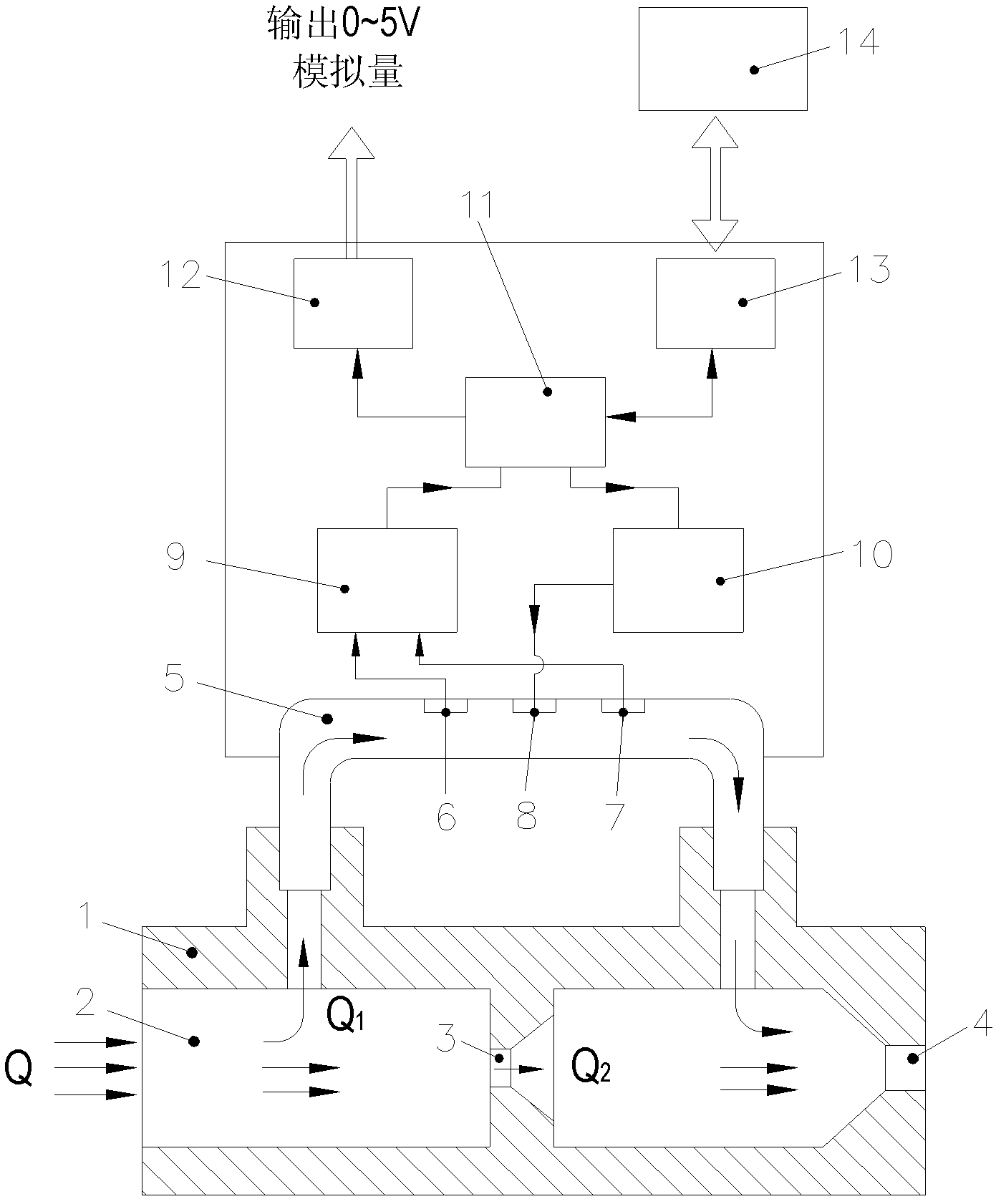

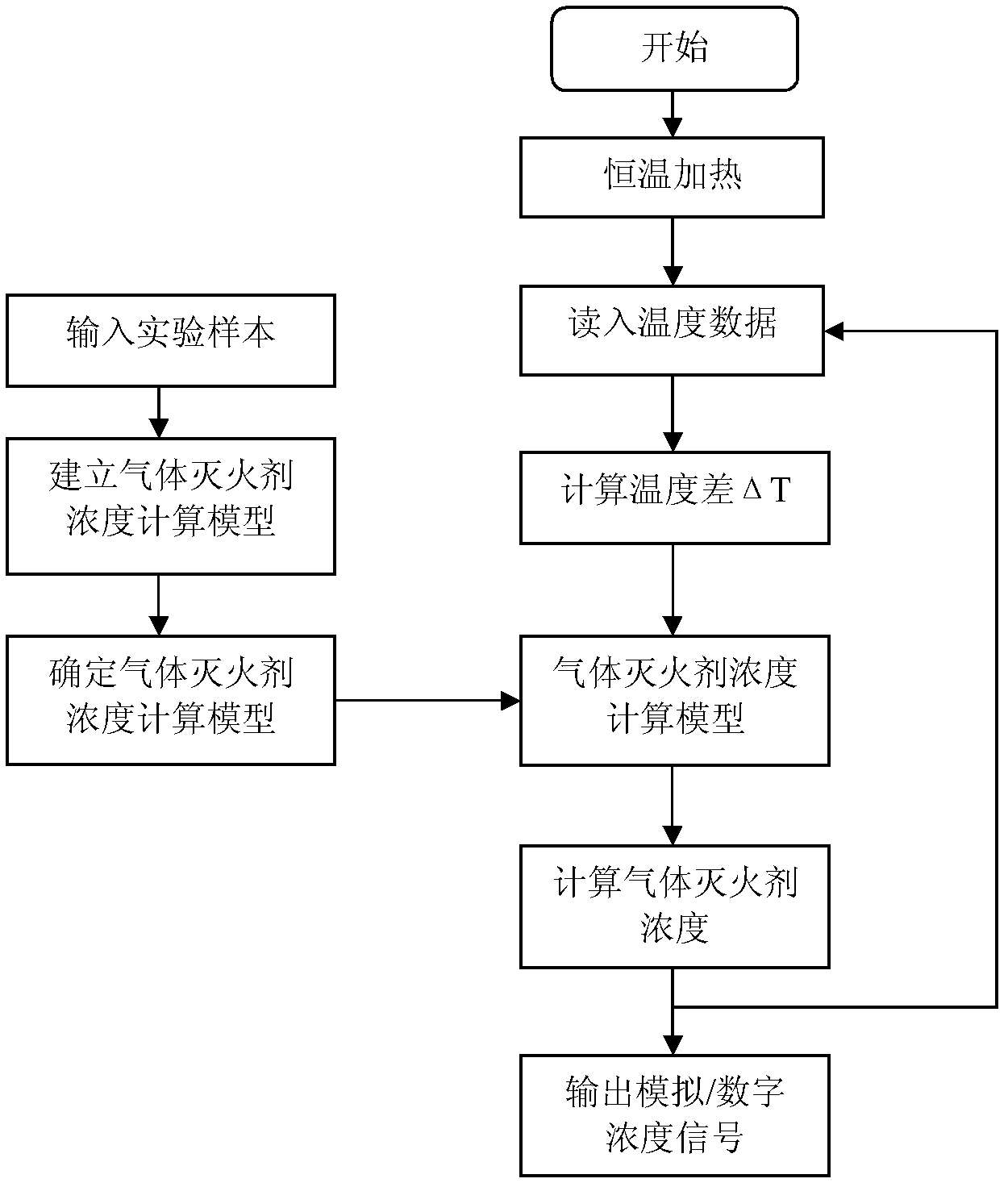

Hot-film gas extinguishing chemical concentration sensing module

The invention discloses a hot-film gas extinguishing chemical concentration sensing module. By the adoption of a diffluence test method, microscale airflow passes through a bypass pipeline, inside which a temperature-sensitive film and a heating film are arranged; the microscale air and a gaseous mixture of the gas extinguishing chemical are heated by the heating film; as the gaseous mixture passes through the temperature-sensitive film, the temperature of the temperature-sensitive film changes and then the resistance value of the temperature-sensitive film changes; voltage value generated from the circuit is outputted, and through signal treatment, a digital signal and an analog signal are outputted. By controlling the flow of gases flowing through the temperature-sensitive film, the temperature change of the temperature-sensitive film is determined by the concentration of the gaseous mixture, and the electric signal generated is processed and outputted so as to obtain the concentration value of the gas extinguishing chemical. The invention can be widely applied in a gas extinguishing chemical concentration test system so as to establish a rapid high-precision gas extinguishing chemical concentration test system.

Owner:UNIV OF SCI & TECH OF CHINA

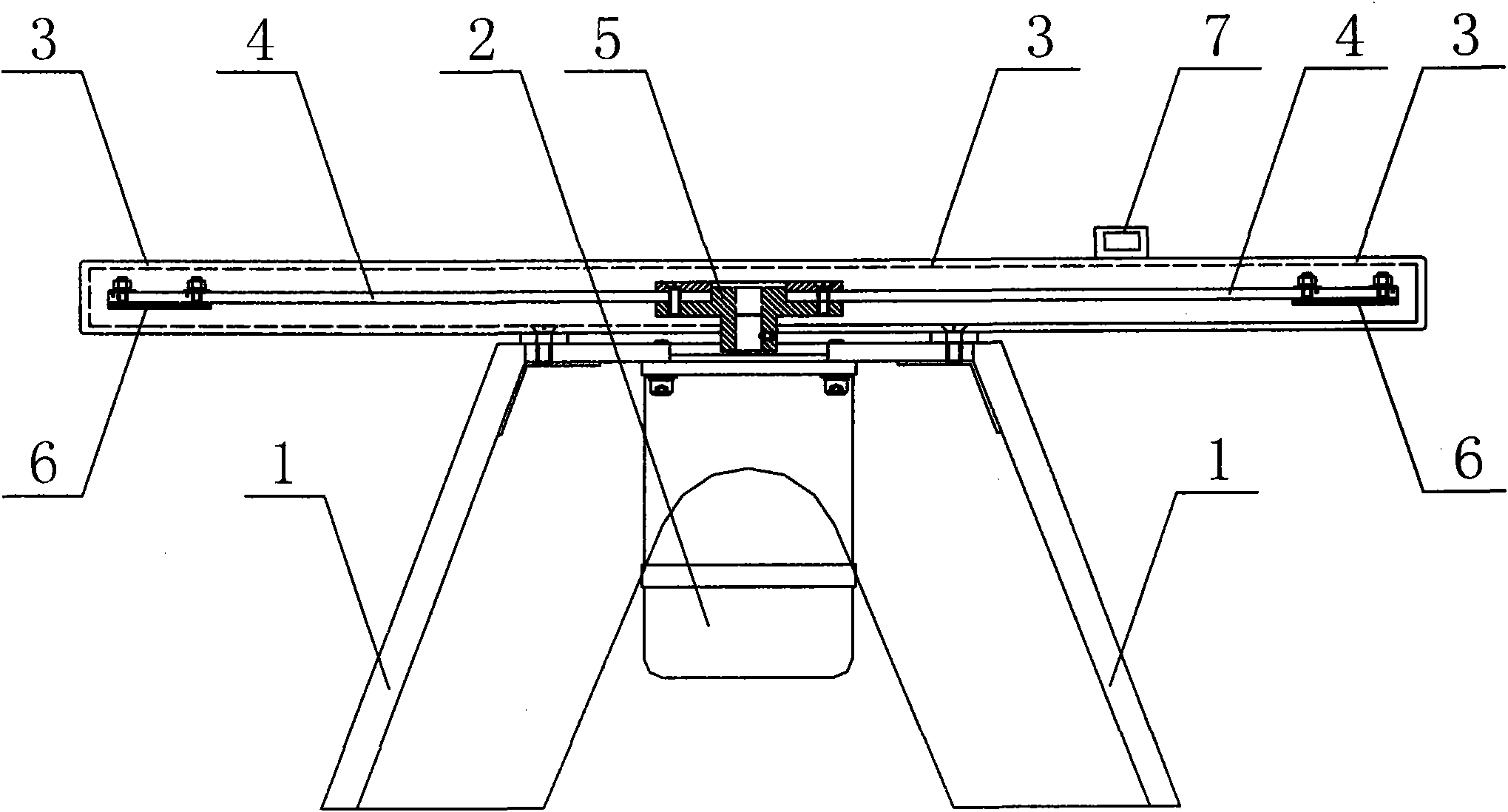

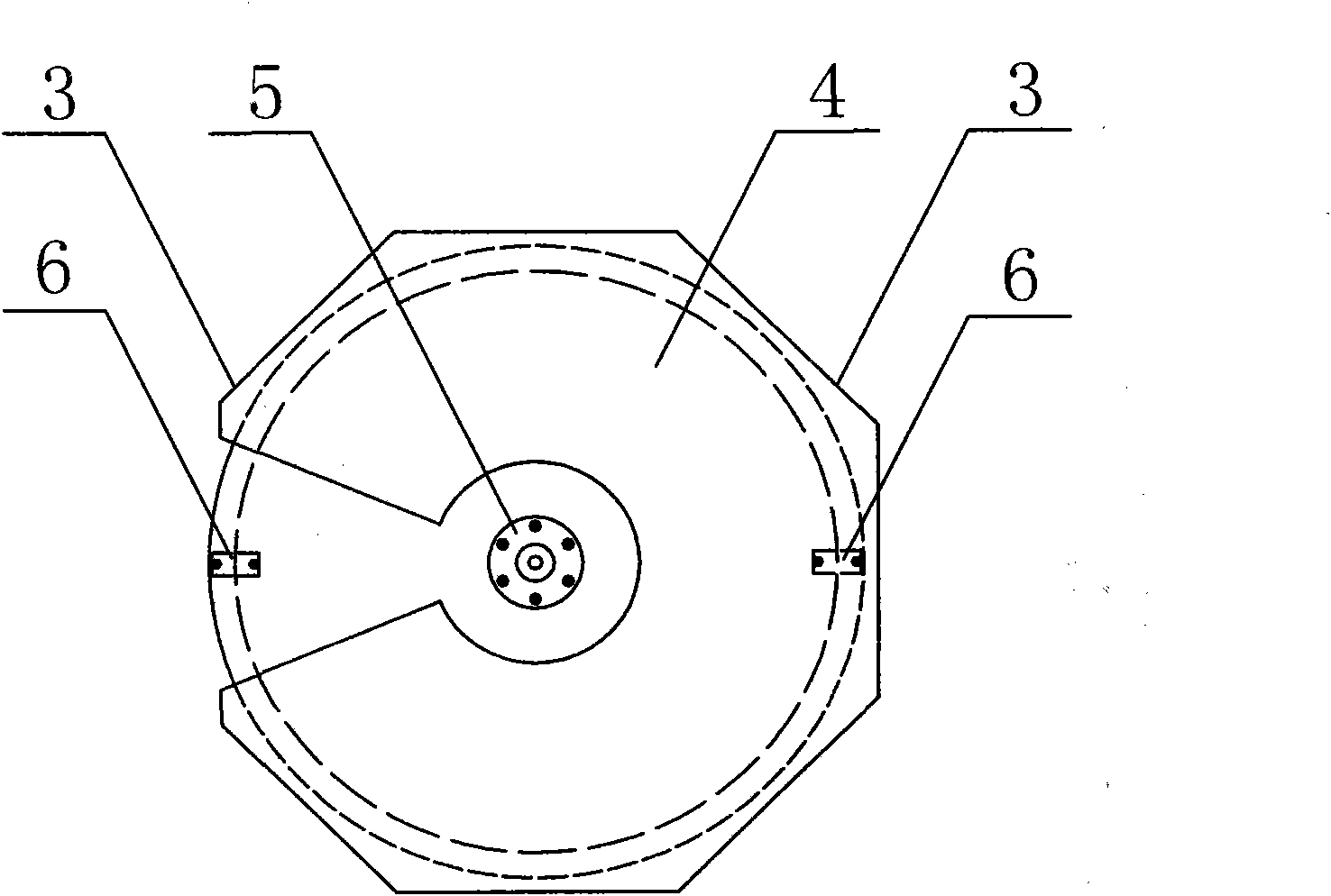

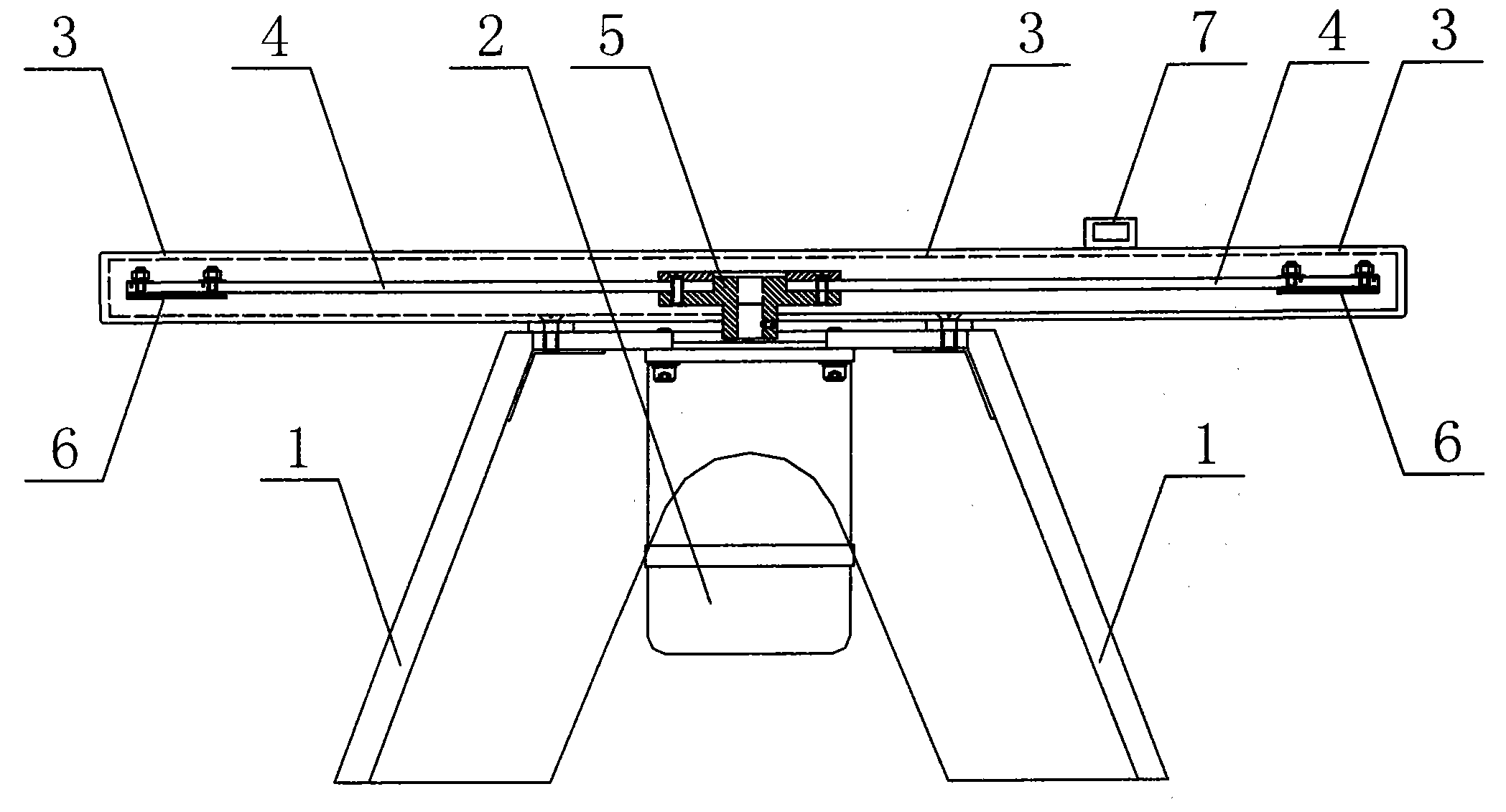

Speed simulator of train

ActiveCN101966852AContinuously adjustable speedGuaranteed uptimeVehicle route interaction devicesElectric machineSpeed test

The invention provides a speed simulator of a train, which comprises a bracket, a motor, a protective cover, a rotating disk, a flange, a speedometer and two shielding sheets, wherein the protective cover is horizontally arranged on the upper part of the bracket; the motor is arranged on the lower part of the bracket; an output shaft of the motor is vertically connected with the middle part of the rotating disk through the flange; the rotating disk is horizontally arranged in the protective cover; the two shielding sheets are symmetrically arranged on the lower side of the rotating disk; and the speedometer is arranged on the rotating disk and the protective cover. The invention provides a device for simulating the train to pass through a magnetic head in a speed of 0 to 350 km / h, which ensures that a quantitative test of the speed of the magnetic head in axle counter equipment is realized; the train speed simulated by the device is continuous and adjustable; the device can safely and stably simulate the constant speed running of the train at any speed point in 0 to 350 km / h; and the difficulty that the speed test of the magnetic head in the axle counter equipment in railway cannot be carried out is solved.

Owner:HENAN SPLENDOR SCI & TECH

An electric bicycle performance testing platform

ActiveCN106053096BWith friction resistance compensation functionFriction resistance compensationVehicle testingDevice WheelElectric vehicle

The invention discloses an electric bicycle performance test platform comprising a rear wheel driving device and a vehicle seat compressing device. The wheel driving device comprises a first rear axle roller and a second rear axle roller. The first rear axle roller and the second rear axle roller are fixed in a mutually parallel way through bearing pedestals. The first rear axle roller is connected with a first motor. The second rear axle roller is connected with a second motor. The rear wheel of a tested vehicle body is arranged in the two rear axle rollers of the rear wheel driving device. The vehicle seat compressing device is used for loading compressing force for the tested vehicle body so as to simulate vehicle-mounted weight. The second motor and the second rear axle roller load positive torque to the rear wheel of the vehicle body to apply push force and the vehicle wheel is enabled to be in the critical operation state so as to compensate frictional force of the test platform and frictional resistance between the vehicle wheel of the electric vehicle and the rollers of the test platform. The first motor and the first rear axle roller load opposite torque to the rear wheel to apply resistance so as to quantitatively simulate the resistance in driving of the electric vehicle.

Owner:天津铭志成科技有限责任公司

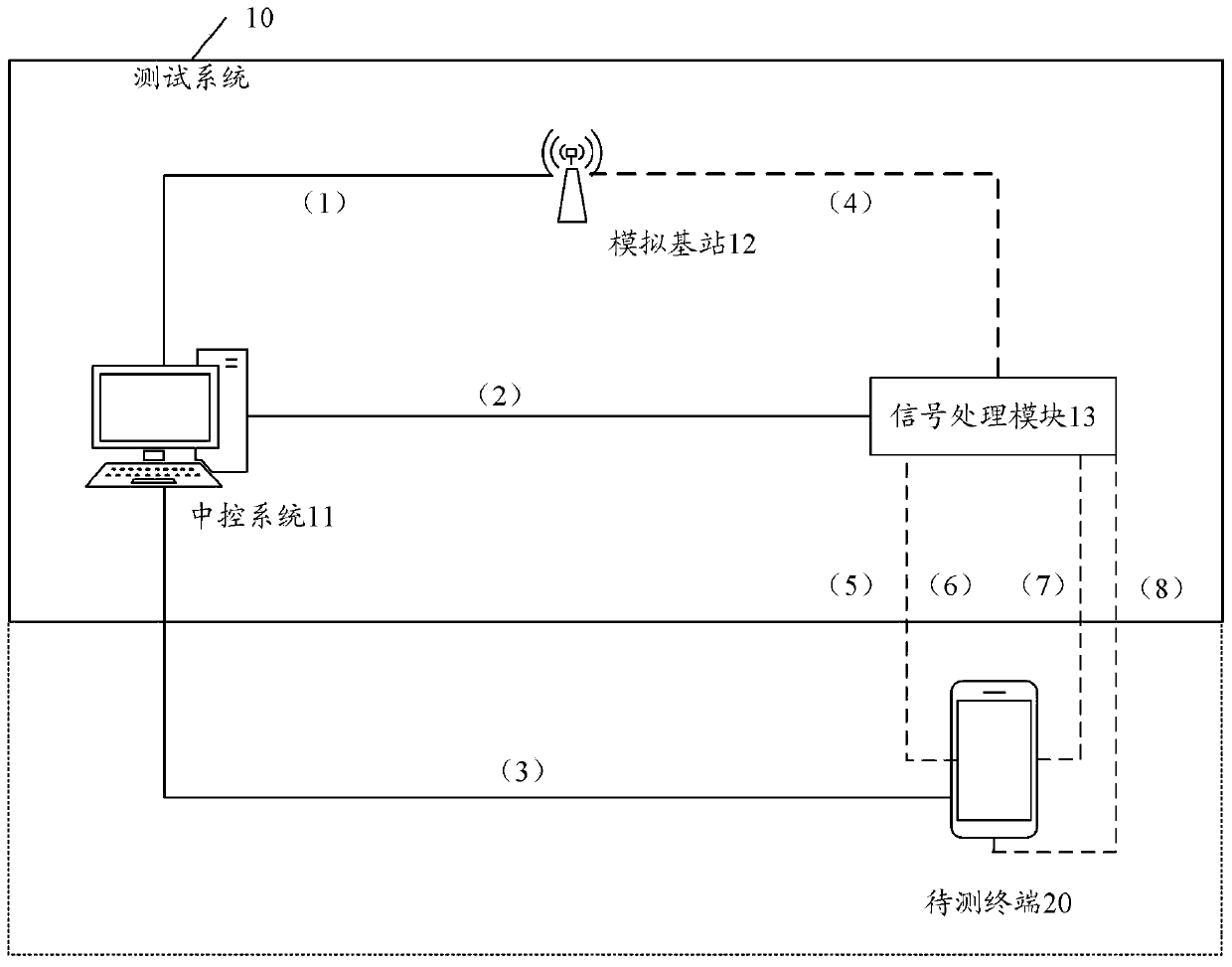

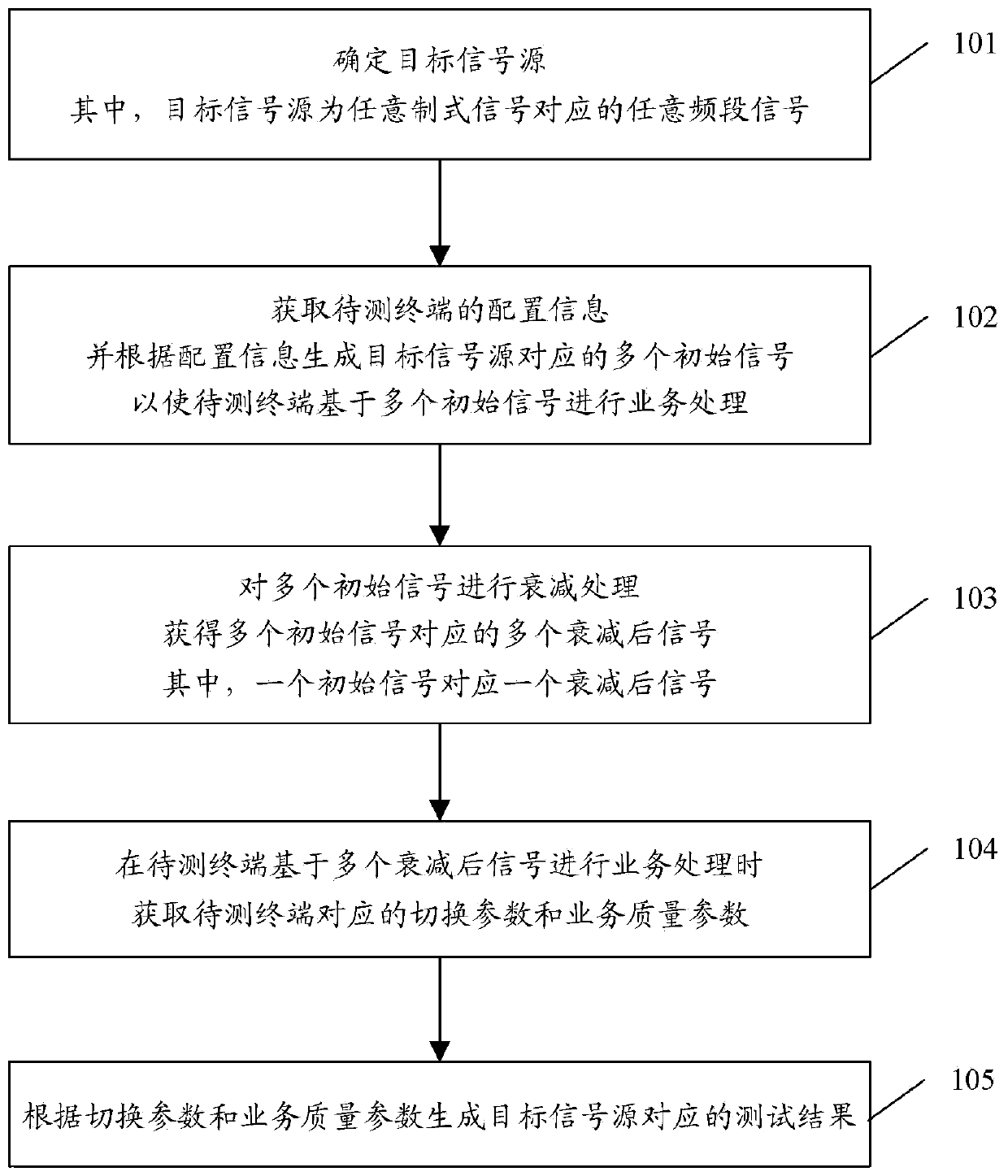

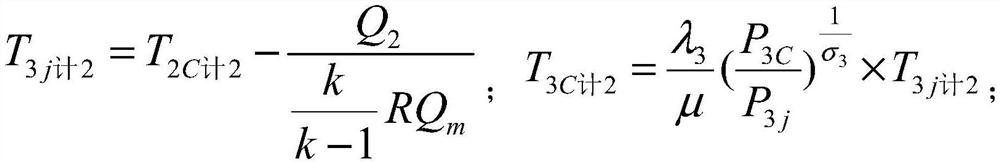

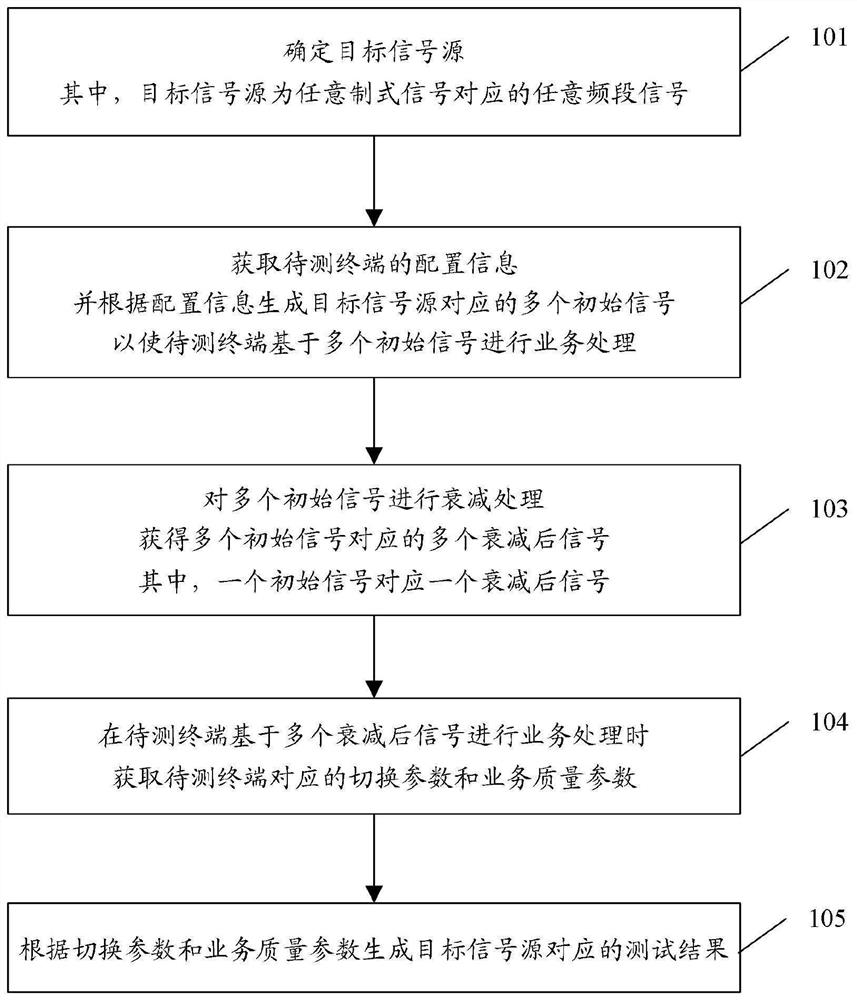

Test method and system and storage medium

ActiveCN111431633AAchieve full coverage testingRealize Quantitative TestingTransmission monitoringWireless communicationTarget signalSignal source

The embodiment of the invention discloses a test method and system and a storage medium. The test method comprises the steps of determining a target signal source; wherein the target signal source isan arbitrary frequency band signal corresponding to an arbitrary standard signal; acquiring configuration information of the to-be-tested terminal, and generating a plurality of initial signals corresponding to the target signal source according to the configuration information, so that the to-be-tested terminal performs service processing based on the plurality of initial signals; performing attenuation processing on the plurality of initial signals to obtain a plurality of attenuated signals corresponding to the plurality of initial signals; wherein one initial signal corresponds to one attenuated signal; when the to-be-tested terminal carries out service processing based on the plurality of attenuated signals, obtaining a switching parameter and a service quality parameter correspondingto the to-be-tested terminal; and generating a test result corresponding to the target signal source according to the switching parameter and the service quality parameter.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

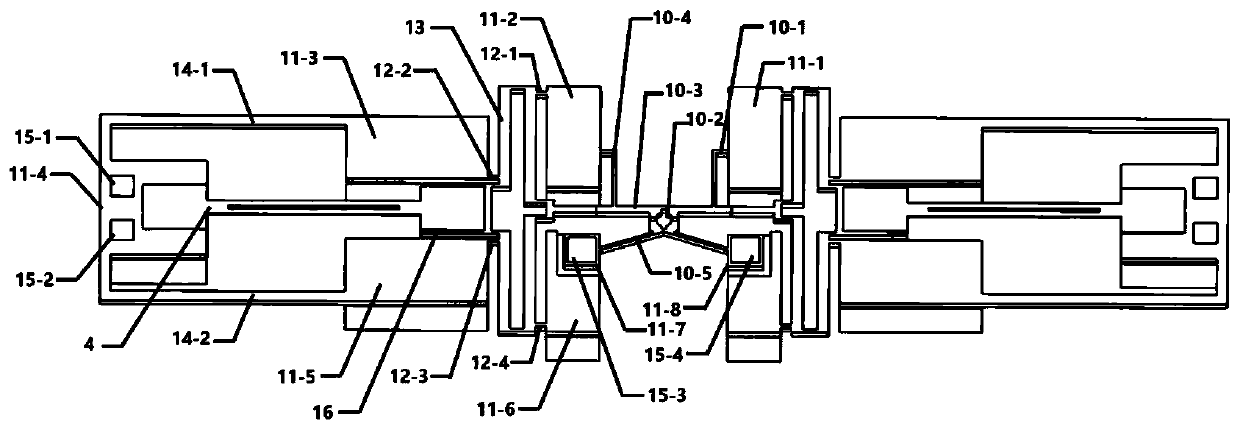

Silicon-based quartz MEMS resonant torque sensor for micro-nano-scale material

ActiveCN110095210AHigh precisionMass-producedForce measurement by measuring frquency variationsMicro nanoTuning fork

The invention relates to a silicon-based quartz MEMS resonant torque sensor for a micro-nano-scale material. The sensor comprises a monocrystalline silicon substrate layer; a silicon dioxide insulating layer is grown on the monocrystalline silicon substrate layer; the silicon dioxide insulating layer is provided with a monocrystalline silicon structural layer; the monocrystalline silicon structural layer comprises a key slot of a linear micro-nano material clamping mechanism; two sides of the key slot are connected with an output beam and the top end of a V-shaped actuating beam; the V-shapedactuating beam is fixed on an anchoring point; the output beam is fixed on the anchoring point through a limiting beam; the two ends of the output beam are connected with the input end of a second-order amplification beam; the second-order amplification beam is fixed on the anchoring point through a fulcrum beam; the output end of the second-order amplification beam is connected with a suspensionplatform; the suspension platform is connected with one end of a quartz double-end fixed tuning fork; the other end of the quartz double-end fixed tuning fork is fixed on the anchoring point; all structures except the anchoring point are in suspended states; a control voltage is applied to the V-shaped actuating beam; and the V-shaped actuating beam moves due to thermal stress, so as to clamp a spline at one end of a linear micro-nano material. The method has the advantages of high precision, low cost and the like.

Owner:XI AN JIAOTONG UNIV

Aircraft front undercarriage steering pressure relief valve moment tester

ActiveCN109159918AImprove securityExtended flight timeAircraft components testingTest efficiencyControl system

An aircraft front landing gear steering pressure relief valve moment tester includes a test aircraft body equipped with movable universal wheels and brakes, pressure relief valve moment test mountingtable, hydraulic circuit control system for testing, Pressure Sensing Testing System, A leak t line for an oil inlet line, As that aircraft front lan gear steering pressure release valve moment testemachine provided by the invention is small in overall outline size, therefore, the aircraft front landing gear steering pressure release valve moment testing machine is very flexible and convenient tooperate and low in cost, and therefore is convenient for t operation of the aircraft front landing gear pressure release valve. At that same time, the t work of the pressure relief valve of various types is easy to be realize, Thus, the test efficiency of the pressure relief valve of the aircraft is improved, the quantitative test is realized, and the safety of the performance test operation of the pressure relief valve of the aircraft landing gear is improved to the maximum extent, thereby reducing the maintenance time of the aircraft, increasing the flight time of the aircraft, and increasing the revenue for the airline.

Owner:HANGCHENG TIANJIN TECH

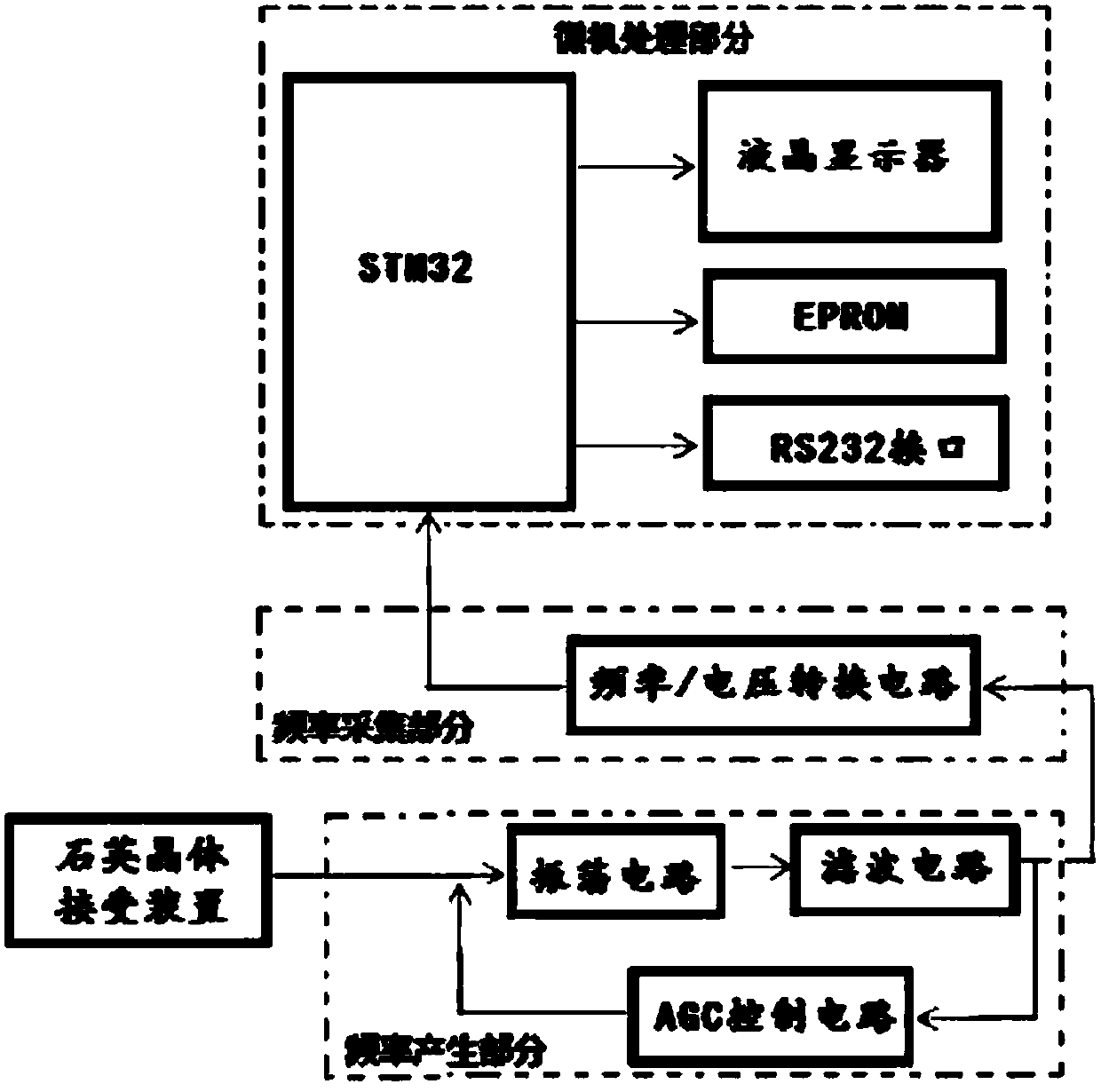

Cell mechanical property tester based on STM32

PendingCN107907588ATimely processingStrong targetingAnalysing fluids using sonic/ultrasonic/infrasonic wavesEngineeringMechanical property

The invention discloses a cell mechanical property tester based on STM32. The cell mechanical property tester based on STM32 comprises a quartz crystal receiving device, a frequency generation part, afrequency collecting part and a microcomputer processing part, wherein the quartz crystal receiving device comprises a quartz crystal and a film electrode; the frequency generation part consists of an oscillation circuit, a filtering circuit and an AGC (automatic gain control) circuit which are sequentially connected; the quartz crystal receiving device is connected with the oscillation circuit through an electric conducting wire; the frequency collecting part comprises a frequency / voltage conversion circuit; the microcomputer processing part comprises an STM32 chip and an external interfacethereof; the frequency / voltage conversion circuit is connected with the STM32 chip through an electric conducting wire. The cell mechanical property tester based on STM32 has the advantages that by adopting the non-invasion and non-marking testing type, the real-time, continuous and long-time testing is realized; the cell mechanical property tester is suitable for the cell mass, and the study andquantitative testing on the cell function can be performed.

Owner:HUNAN AGRICULTURAL UNIV

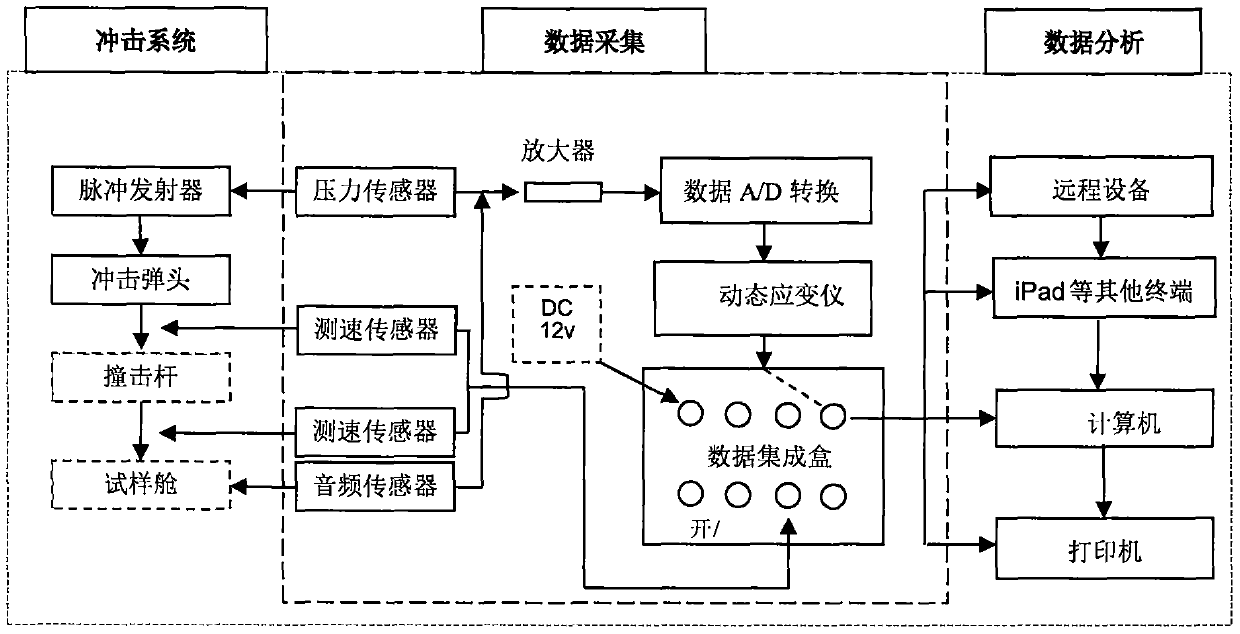

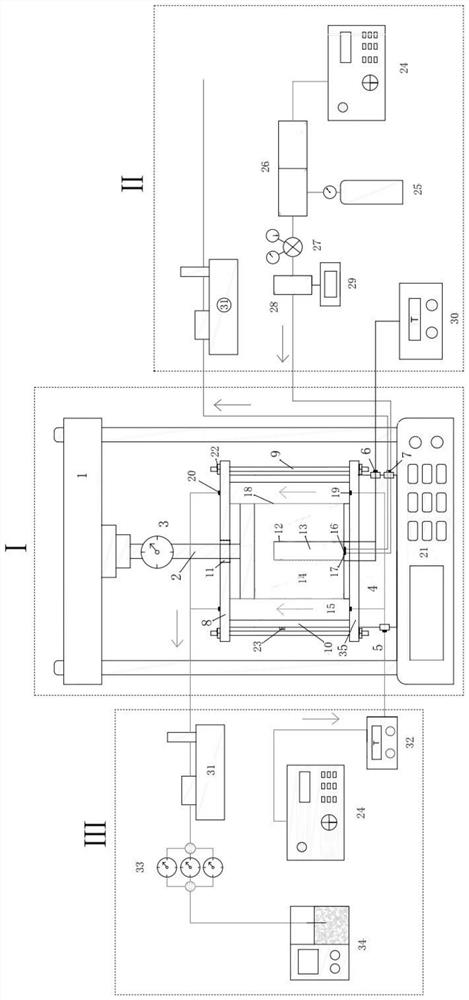

Material characteristic impact acoustic response test simulation system

PendingCN110146394AStrength determinationRealize Quantitative TestingSubsonic/sonic/ultrasonic wave measurementStrength propertiesPressure triggeringHardness

The invention discloses a material characteristic impact acoustic response test system. The system is composed of three parts, namely an impact system, a data collection system and a data analysis system, wherein the impact system is composed of a pressure trigger, an impact elastic head, a ramming rod and a sample bin and is used for impacting a material and generating an audio signal; the data collection system is composed of a pressure sensor, a speed sensor, an audio sensor and the like and is used for collecting sound information generated in the impacting process; and the data analysis system is composed of a computer, an oscilloscope and other terminals and is used for processing and analyzing data through software. The system is characterized in that an impact response test on thematerial is implemented, and the structure, damage, yield strength, damage strength, sound elasticity modulus, hardness, density and other parameters of the material are measured through an audio characteristic test on sound generated when the material is impacted. The system can be suitable for quantitative testing of the dynamic characteristics of the structure and strength of various hard materials.

Owner:谭乃根

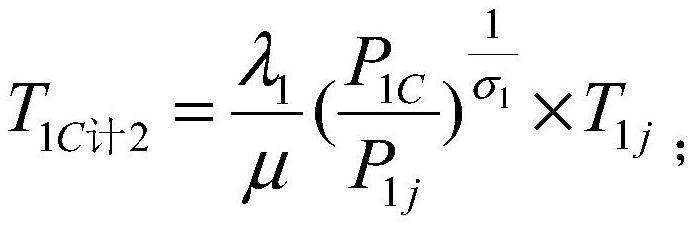

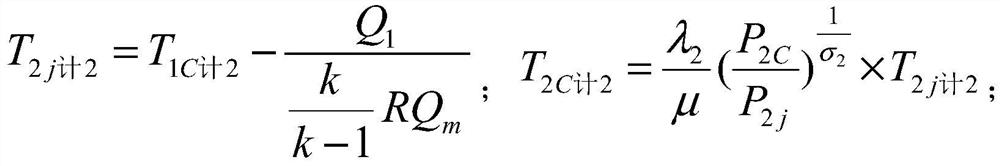

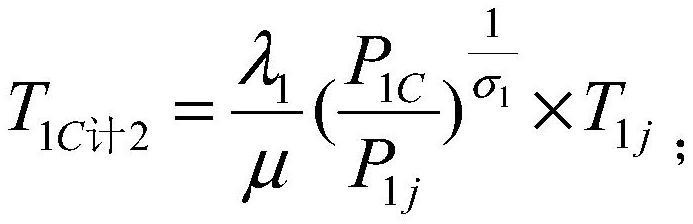

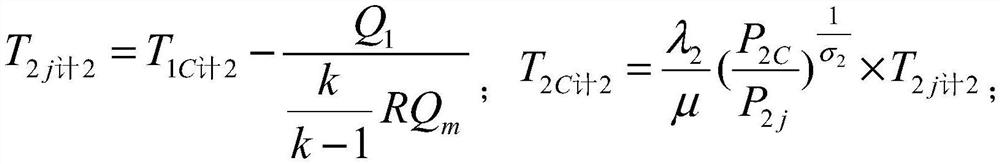

Isothermal compressor performance test calculation method

ActiveCN112459984ARealize Quantitative TestingHigh precisionPump testingPositive displacement pump componentsCorrelation coefficientComputation process

The invention provides an isothermal compressor performance test calculation method. The method comprises the steps that step 1, parameters of an isothermal compressor are collected; step 2, multivariable numbers in a calculation process are preliminarily determined, specifically, in step 201, inlet and outlet pressure and temperature parameters of all stages of the design modal are obtained, in step 202, the multivariable numbers of all stages of the design modal are calculated, in step 203, the multivariable numbers of all stages of the test modal are preliminarily determined, specifically,the multivariable numbers of all stages of the test modal are made to be equal to the multivariable numbers of all stages of the design modal; step 3, test data are preliminarily calculated; step 4, data comparison and correlation coefficient selection iterative calculation are performed, specifically, the complete machine power N calculated in the step 3 is compared with the actually measured power N, a correlation power adjustment coefficient is calculated, the multivariable numbers of all stages are recomputed, specifically, the multivariable numbers of all stages of the test modal are re-determined, the multivariable numbers of all stages of the test modal are made to be equal to the multivariable numbers of all stages obtained by re-calculation, and the calculations in the step 3 andthe step 4 are repeatedly iterated; and step 5, correlation property parameters are calculated.

Owner:XIAN SHAANGU POWER

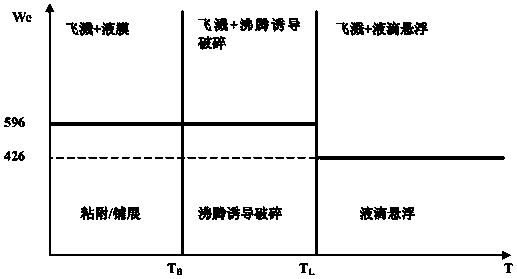

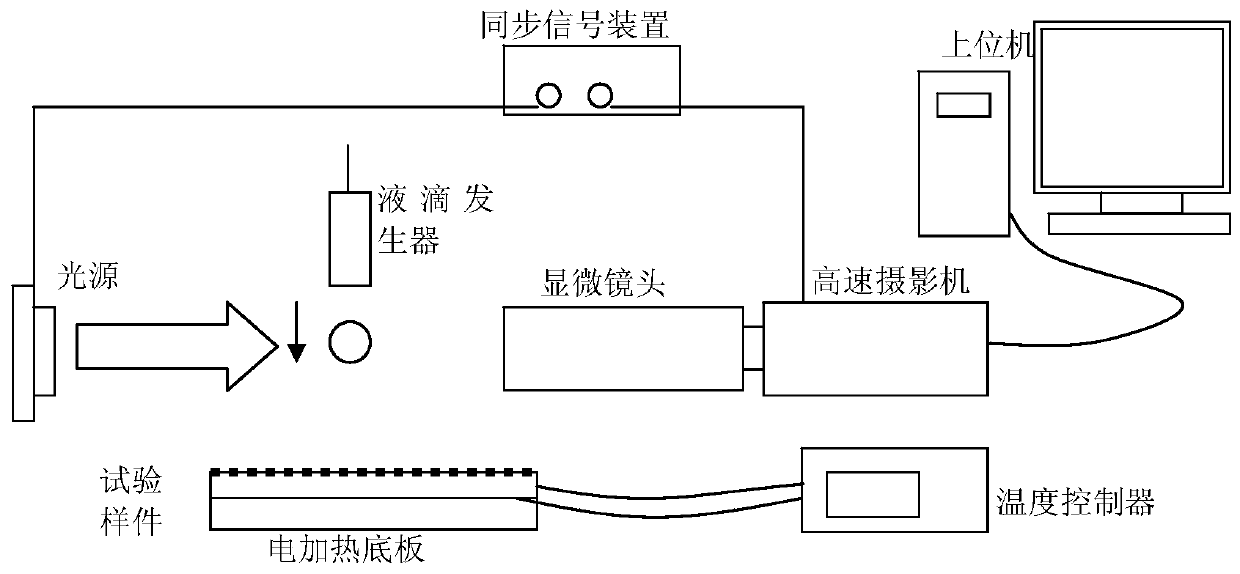

A test system and method for evaluating the effect of liquid film cooling on a coated combustion chamber wall surface

ActiveCN107966529BRealize Quantitative TestingInvestigating moving fluids/granular solidsCombustion chamberMathematical model

Owner:BEIJING INST OF CONTROL ENG

Double-channel second-order nonlinear optical test system

ActiveCN102192899BSimple structureEasy to operateAnalysis by material excitationResponse sensitivitySingle crystal

The invention discloses a double-channel second-order nonlinear optical test system which is used for testing the second-order nonlinear optical effects of materials. The system comprises a laser light source, a photic sheet, a sample rack, a focusing lens, a spectroscope, a first optical filter, a first photomultiplier, a second optical filter, a second photomultiplier, a signal receiving analyzer and a photophobic box. According to the intensities of frequency-doubled lasers and non-frequency-doubled lasers contained in optical signals generated by exciting samples by lasers and the relative intensity relationship thereof, the laser-induced optical signal lights after respectively passing through the first optical filter and the second optical filter are subjected to two-channel exploration by virtue of the first and second photomultipliers, then through carrying out comparison and analysis on signals generated through two-channel exploration, the qualitative and quantitative test on the second-order nonlinear optical effects of powder-monocrystal containing samples is realized. The double-channel second-order nonlinear optical test system is simple in structure, light, practical, and easy to operate, has the advantages of wide waveband application range, high response sensitivity, and the like; and by using the system, the qualitative and quantitative test on the second-order nonlinear optical effects of sample materials can be effectively realized, therefore, the system has the advantages of broad application prospect and high application value.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Detection method for internal atmosphere of vacuum packaging device, airtight container and detection equipment

PendingCN114324546AAdvanced technologyRealize Quantitative TestingMaterial analysis by electric/magnetic meansProcess engineeringAtmospheric sciences

The invention relates to a method for detecting the internal atmosphere of a vacuum packaging device, an airtight container and detection equipment. According to the method for detecting the internal atmosphere of the vacuum packaging device, the vacuum packaging device is placed in the airtight container, the airtightness of the vacuum packaging device is damaged, the internal atmosphere of the vacuum packaging device is mixed with the internal atmosphere of the airtight container, and extremely little atmosphere in the vacuum packaging device is mixed into enough atmosphere. The internal air pressure of the airtight container is higher than that of the vacuum packaging device, the mixed atmosphere can be detected through a conventional method, and due to the fact that the internal atmosphere of the airtight container is known, after the mixed atmosphere is detected, the components and the content of the components of the internal atmosphere of the vacuum packaging device can be calculated. According to the detection method, the limitation of existing detection equipment can be broken through, quantitative testing of the internal atmosphere of the vacuum packaging device is achieved, and improvement of the vacuum packaging device technology and work such as DPA, failure analysis and mechanism analysis reliability research can be effectively supported.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST THE FIFTH ELECTRONICS RES INST OF MIITCEPREI LAB

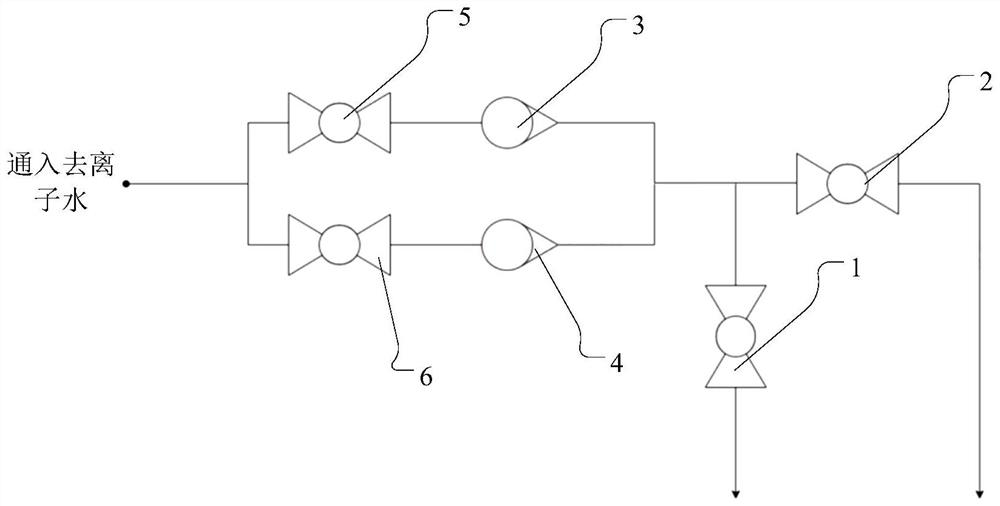

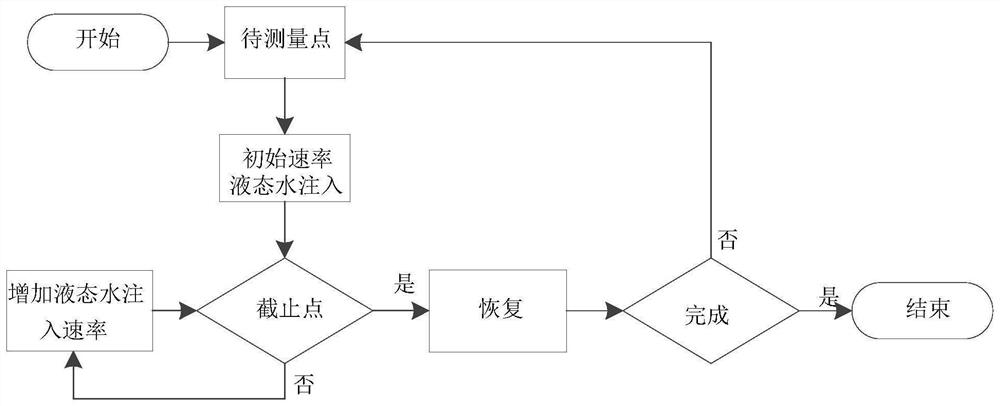

Method and device for testing liquid water tolerance of cathode and anode of fuel cell stack

PendingCN114335623ARealize Quantitative TestingWater management in fuel cellsThermodynamicsFuel cells

The invention discloses a fuel cell stack cathode and anode liquid water tolerance testing device and method. The fuel cell stack cathode and anode liquid water tolerance testing device comprises a rate adjusting assembly and a voltage measuring instrument, an outlet of the rate adjusting assembly is communicated with a target flow channel of the to-be-measured fuel cell stack and is used for outputting liquid water to the target flow channel; the voltage measuring instrument is electrically connected with each single cell in the fuel cell stack to be measured and is used for measuring the voltage of each single cell; and when the index measured by the voltage measuring instrument reaches a cut-off point, the rate of outputting the liquid water by the rate adjusting assembly is the maximum tolerance rate of the liquid water of the fuel cell stack to be measured. According to the method, the liquid water is directly injected into the target flow channel, and the maximum tolerance rate of the liquid water of the fuel cell stack is obtained, so that the liquid water tolerance test result of the fuel cell stack is quantified, and guidance is provided for the design and structure optimization of the fuel cell stack.

Owner:WEICHAI POWER CO LTD

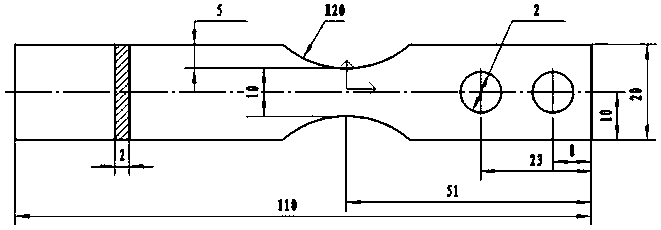

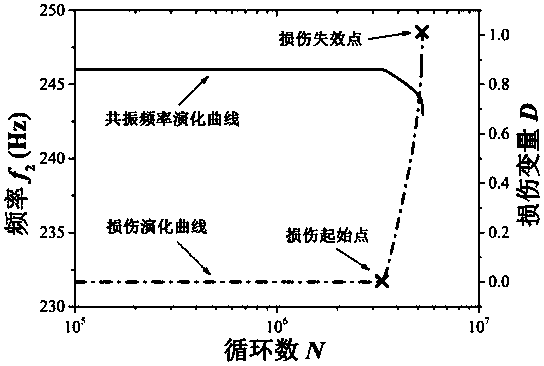

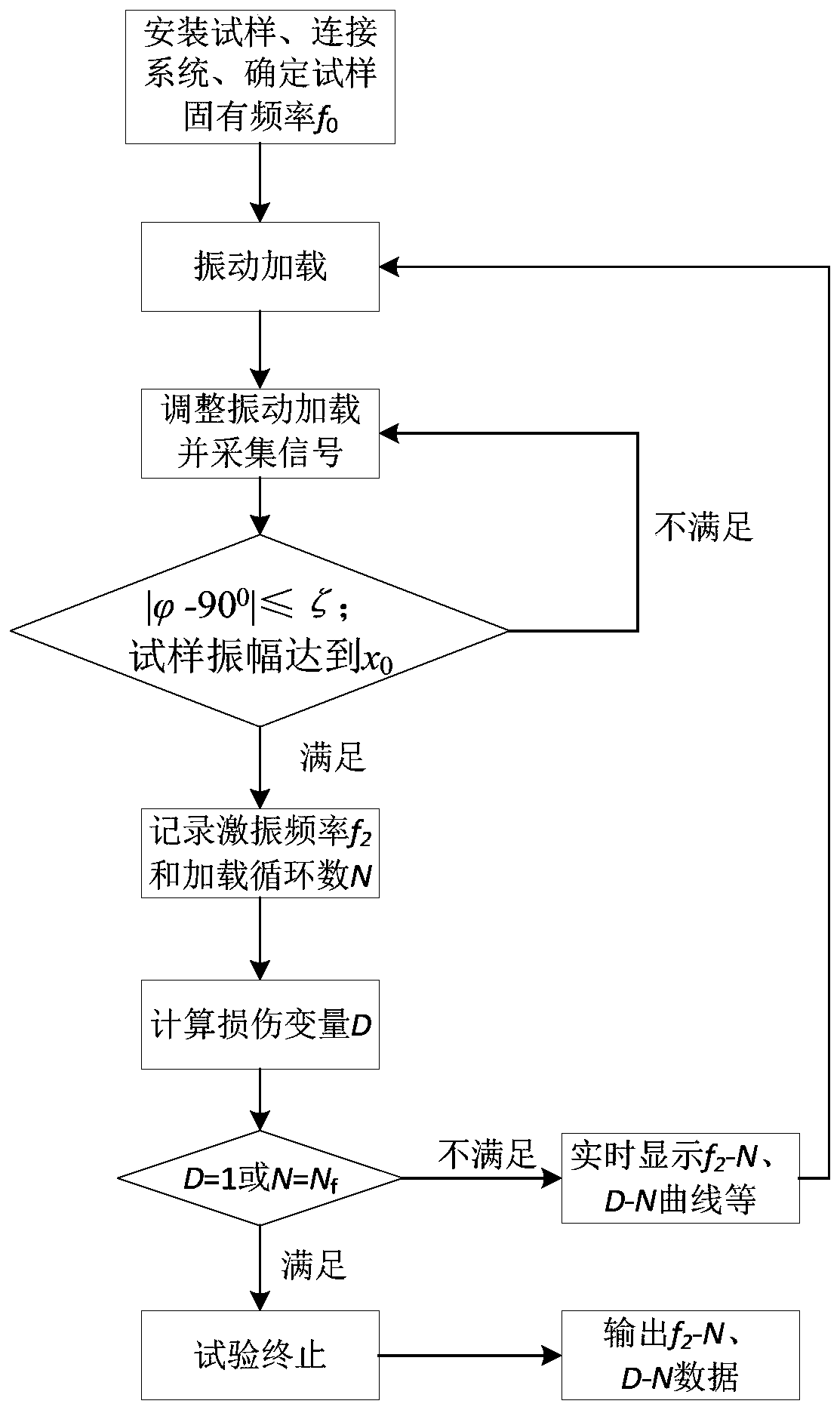

A Quantitative Test Method for the Whole Process of Damage Evolution in Vibration Fatigue Test

ActiveCN108548646BRealize Quantitative TestingImprove accuracyMaterial strength using repeated/pulsating forcesVibration testingFatigue damageAccelerometer

The invention relates to a damage evolution overall process quantitative test method in a vibration fatigue test; the method comprises the following steps: using a laser displacement sensor to synchronically record a displacement sinusoidal signal of a sample; using an accelerometer to synchronically record an exciting acceleration signal of a vibration test equipment table; using a phase difference discrimination method to accurately capture an inherent frequency of the sample in the vibration fatigue process, real time tracking and recording an inherent frequency changing process, thus realizing the damage evolution overall process quantitative test in the vibration fatigue test. The test method can online obtain the overall process of the sample from the damage start to the damage evolution in the whole vibration fatigue test full life period, is low on test equipment requirements, high in data accuracy, and large in data result reference meanings. The method can provide important application values for studying fatigue damage characteristics and fatigue life rules of materials and structures.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

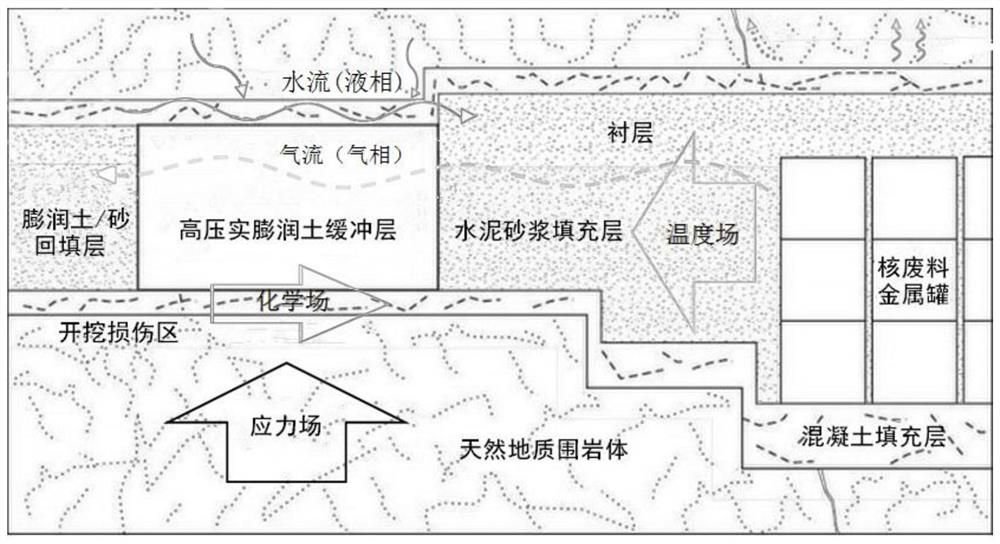

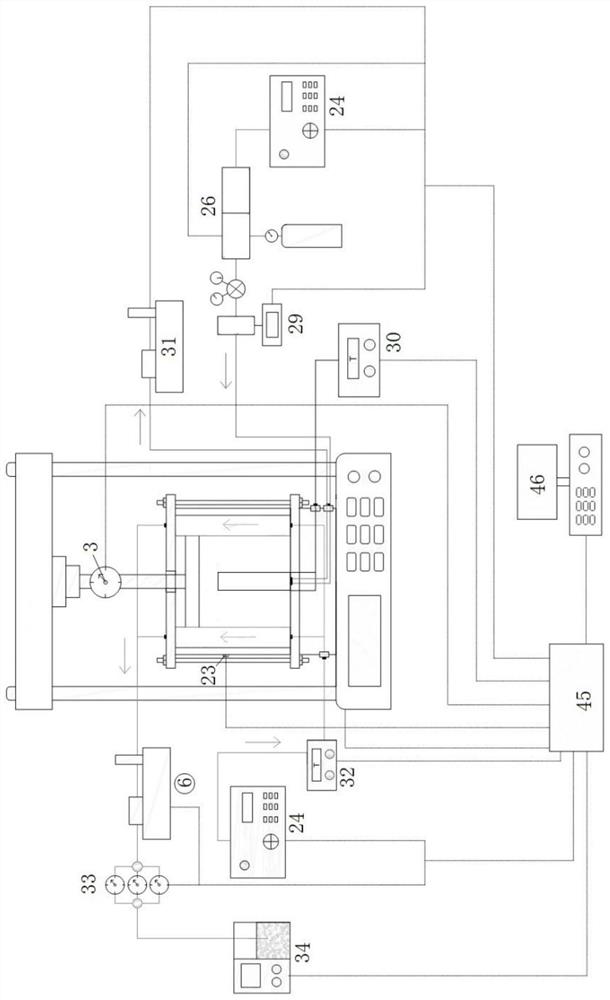

Unsaturated bentonite corrosion test system and method in multi-field coupling environment

ActiveCN113702272AReduce connection transitionsFix articulation issuesWeather/light/corrosion resistancePreparing sample for investigationTemperature controlDeep geological repository

The invention relates to an unsaturated bentonite corrosion test system and method in a multi-field coupling environment. The system comprises a multi-field sensing control triaxial corrosion device, a strain servo shaft stress loading unit, a temperature control gas phase control unit, a temperature control speed control liquid phase seepage control unit and a corrosion whole process real-time monitoring unit. Compared with the prior art, the corrosion behavior and development process of the unsaturated bentonite can be intuitively monitored and measured in real time, and the corrosion rule of the unsaturated bentonite in complex chemical, stress and temperature fields can be accurately obtained; an aqueous solution pressure and a gas pressure are respectively applied and controlled from the outside and the inside of a compacted bentonite sample in a triaxial corrosion chamber, and a temperature field similar to a high-level radioactive waste deep geological repository environment is applied in the sample, so that the influence of a multi-field coupling effect of the high-level radioactive waste deep geological repository environment on unsaturated bentonite corrosion is simulated; and the corrosion behavior and rule of unsaturated bentonite in a high-level radioactive waste deep geological repository environment are truly simulated.

Owner:SHANGHAI JIAO TONG UNIV

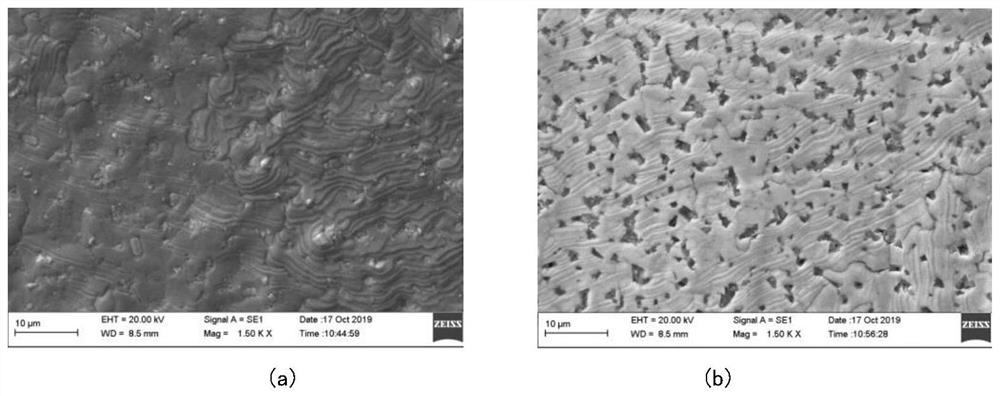

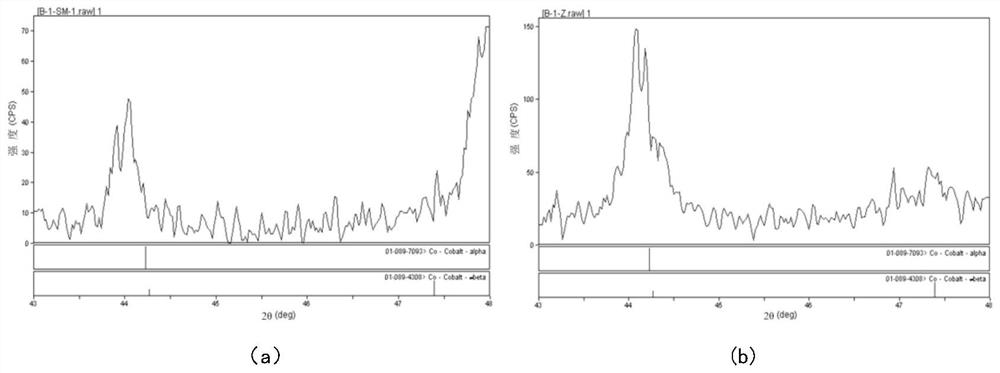

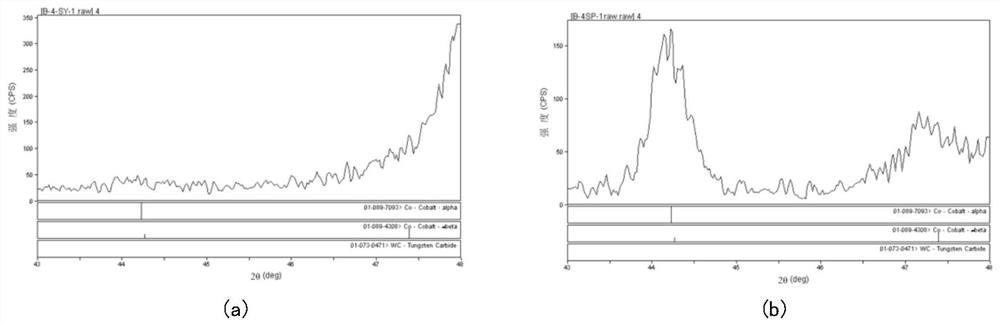

Sample preparation method suitable for hard alloy cobalt phase structure X-ray diffraction method test

PendingCN114878606AEliminate distractionsRealize Quantitative TestingMaterial analysis using wave/particle radiationNuclear energy generationCemented carbideCorrosion

The invention discloses a sample preparation method suitable for X-ray diffraction method test of a hard alloy cobalt phase structure, which comprises the following steps: by taking any plane of a hard alloy sample as a test surface, placing the sample in a container filled with an etchant solution with the test surface upward; the etchant solution is an isovolumetric mixed solution of a potassium ferricyanide solution and a sodium hydroxide solution with the mass concentration of 10%-20%, the etchant solution submerges the test surface of the sample, the corrosion time is not shorter than 16 h, and after corrosion is finished, the sample is taken out, cleaned and wiped dry to be measured. According to the sample preparation method, electrolytic polishing or electrolytic extraction equipment is not used, WC grains on the surface layer of the WC-Co hard alloy sample are directly corroded and removed by adopting a chemical reagent solution, so that the interference of a WC phase diffraction peak is eliminated, and the method is simple and convenient and is suitable for research, development, production, analysis and sample preparation.

Owner:ZIGONG CEMENTED CARBIDE CORP

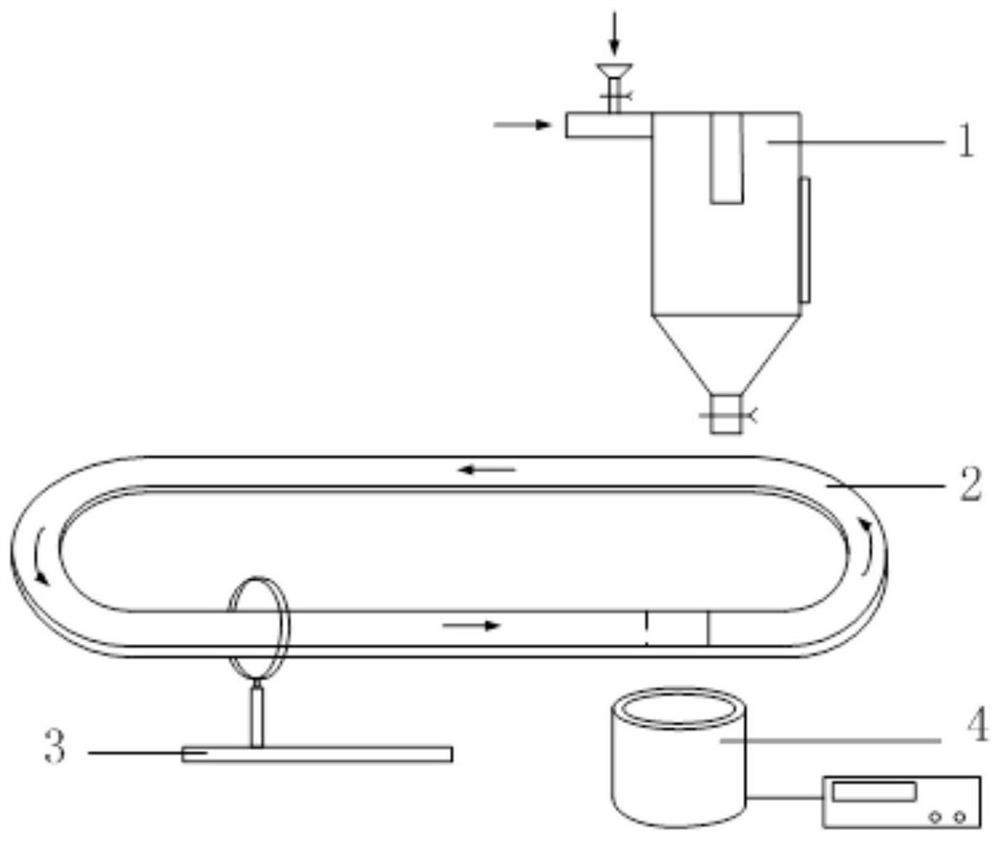

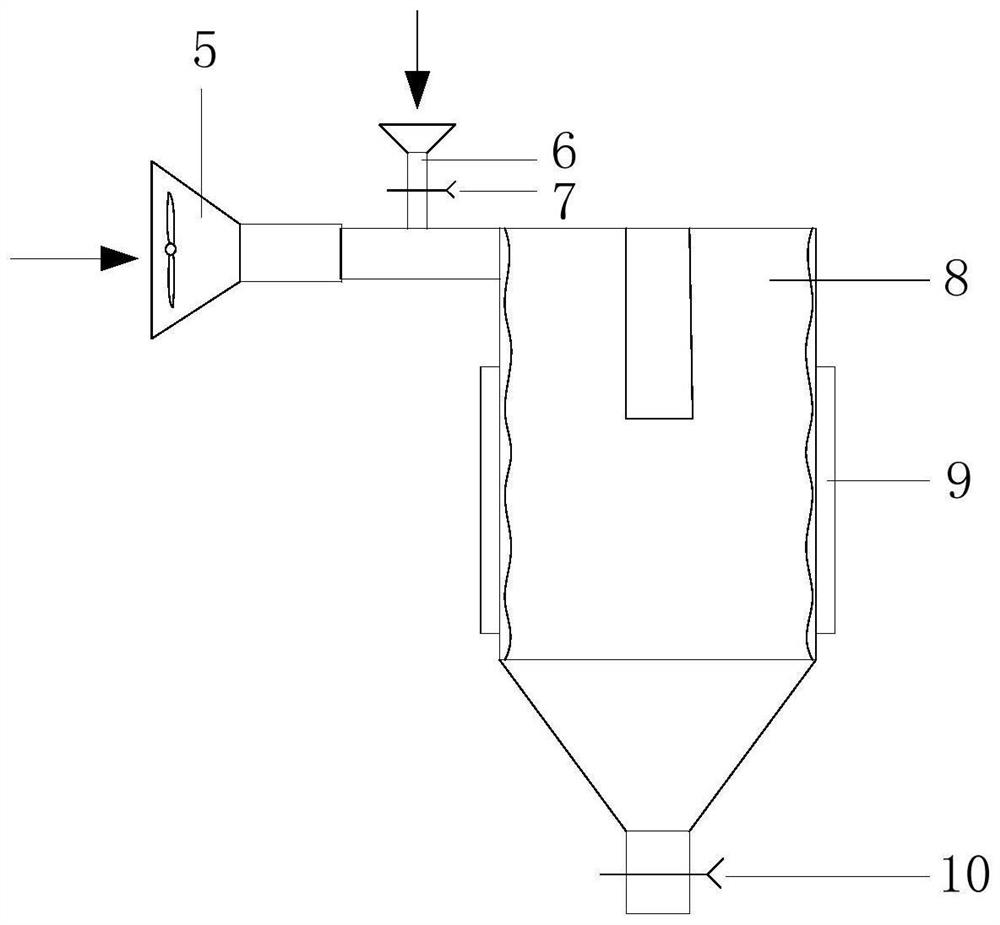

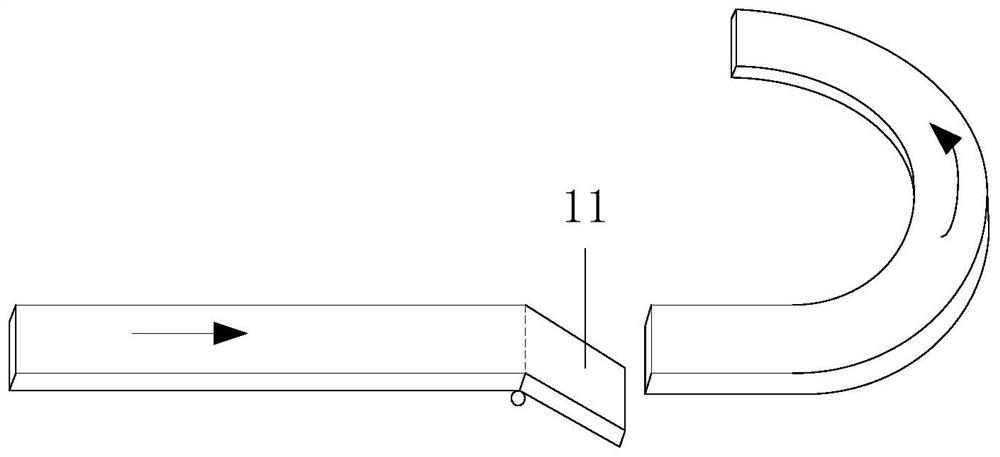

An electrostatic sensor cycle test device

ActiveCN111947690BRealize Quantitative TestingFully chargedElectrical measurementsConverting sensor output electrically/magneticallyCyclic testControl engineering

The invention discloses an electrostatic sensor cycle test device, which belongs to the electrostatic induction sensor technology; it includes an object charging device, an object transmission device, an electrostatic sensor support positioning device, and an object charge measurement device; compared with the prior art, it can realize the Quantitative testing of electrostatic induction sensors, cyclic testing of the same charged object, testing of inductive characteristics at different positions of electrostatic sensors, comparative testing of different types of electrostatic sensors, etc. The technical effects of quantitative characterization, material saving, stability and reliability, and many test items can provide a basis for the optimization design of the electrostatic sensor structure, the performance improvement of the monitoring system, and the analysis and processing of monitoring signals.

Owner:AVIC BEIJING CHANGCHENG AVIATION MEASUREMENT & CONTROL TECH INST +2

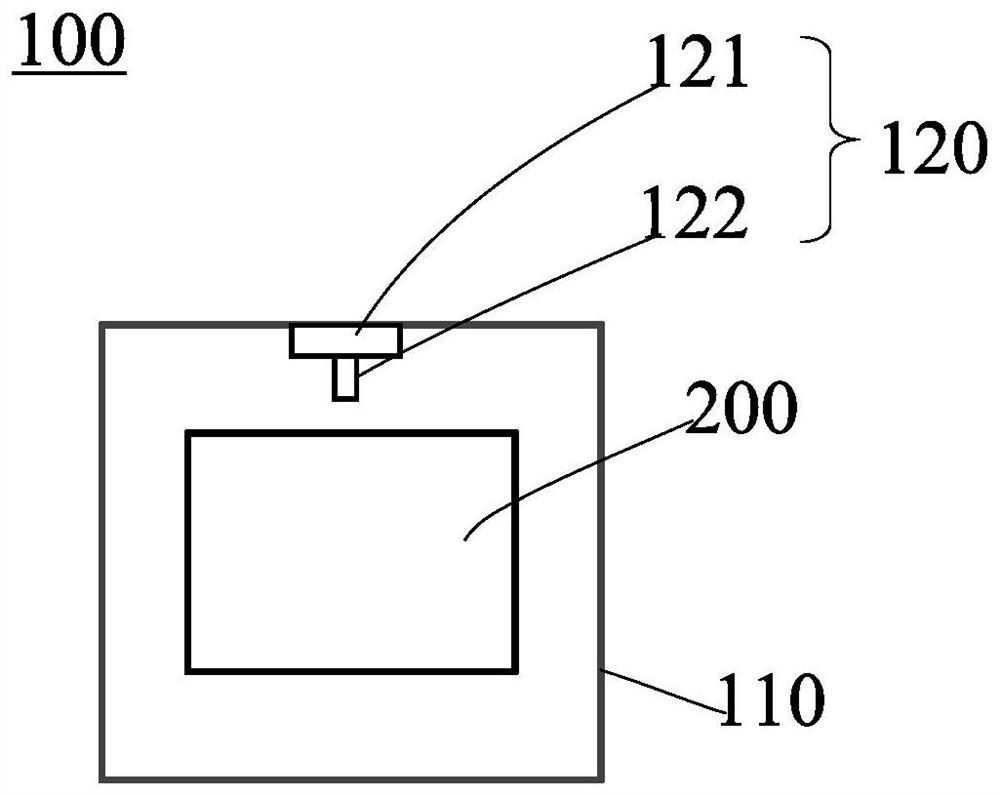

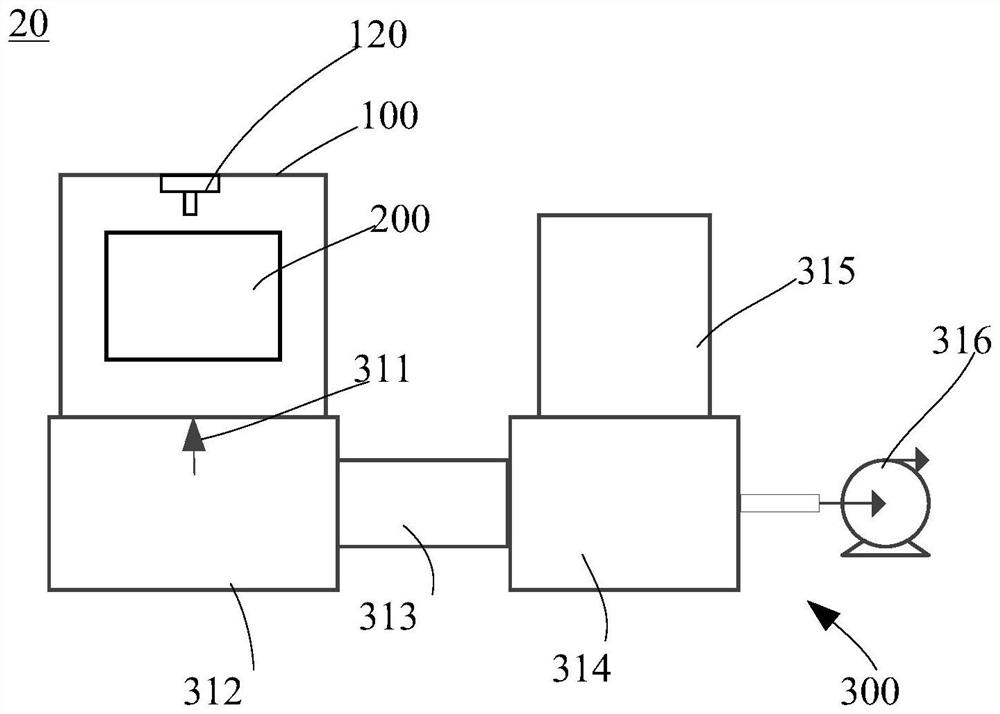

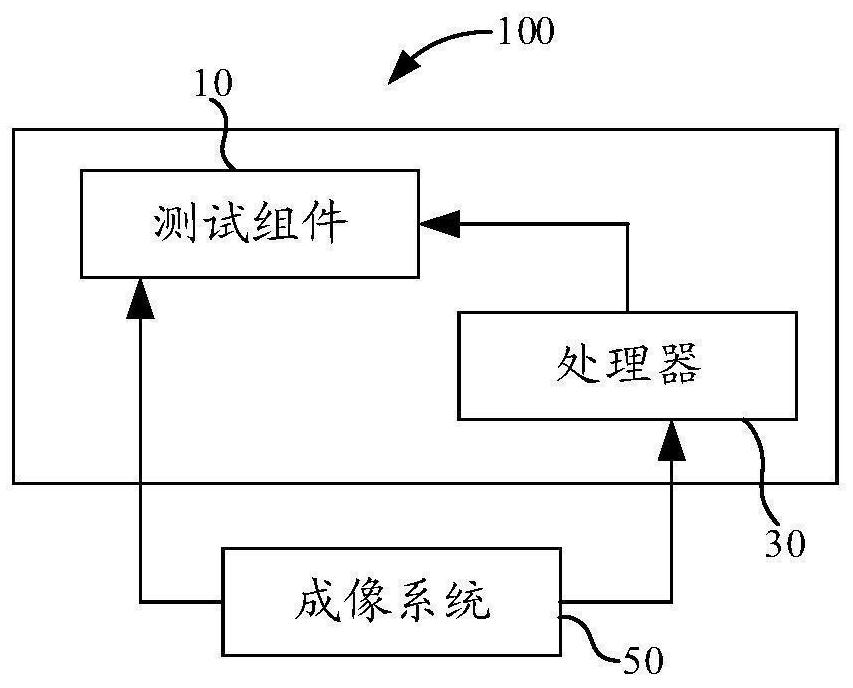

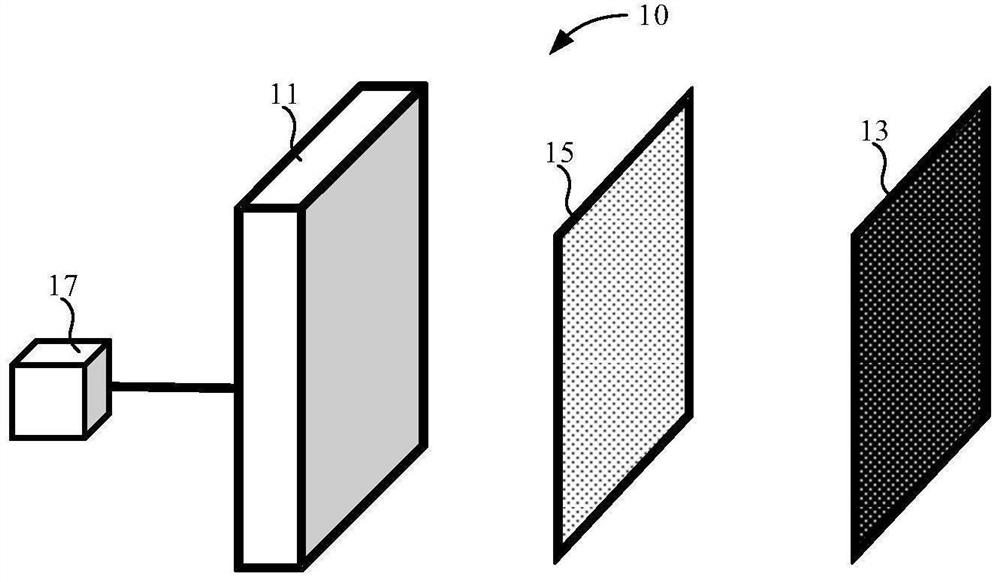

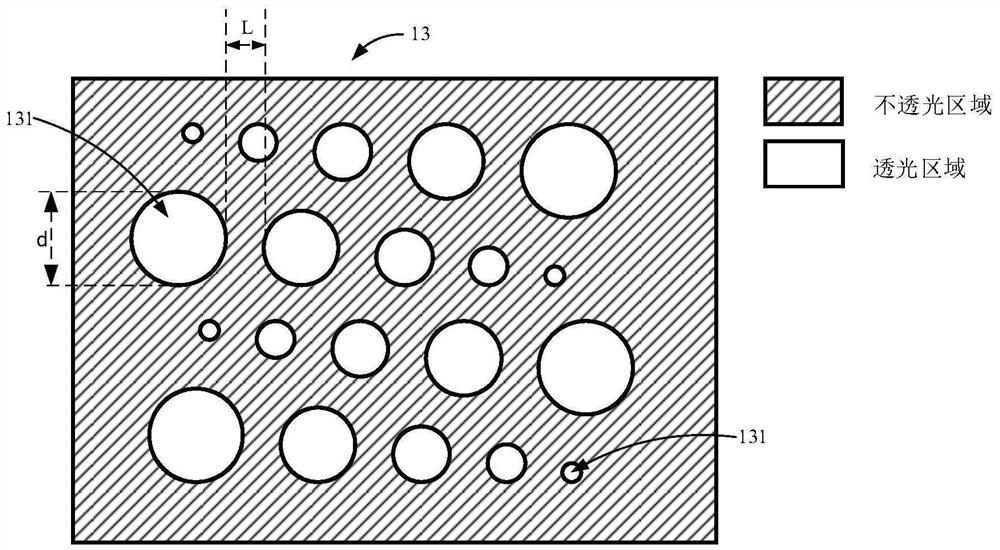

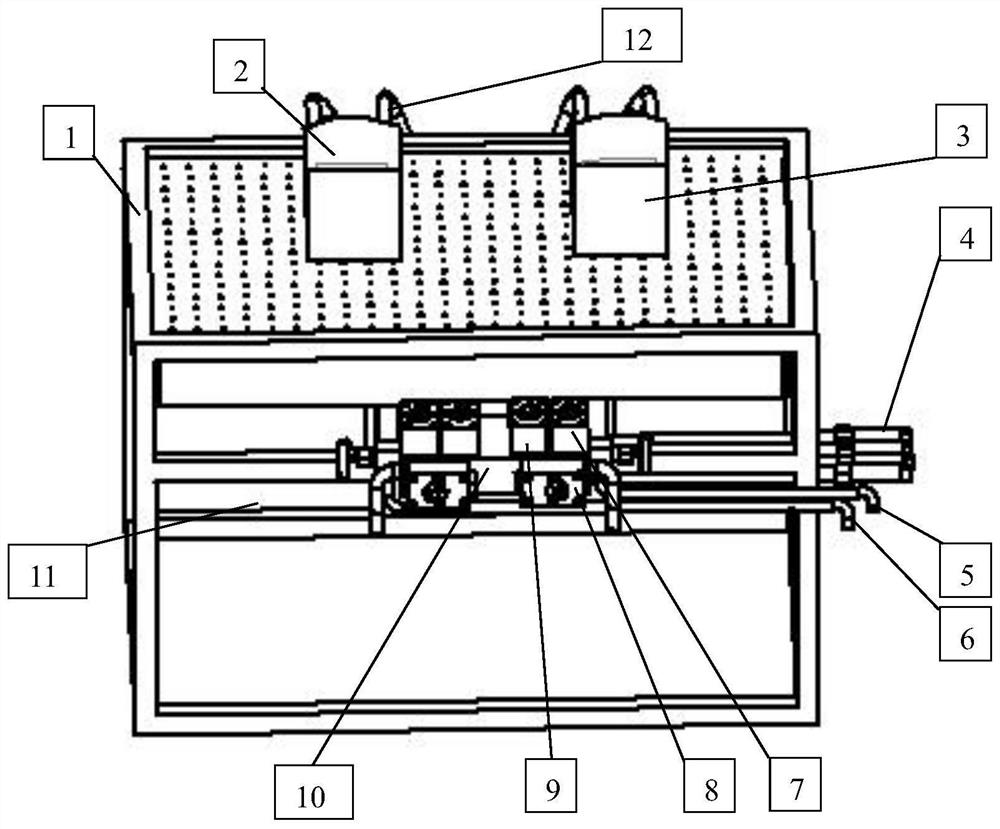

Testing equipment, testing method and testing device based on imaging system

The invention provides testing equipment, a testing method and a testing device based on an imaging system. The testing equipment comprises a light source and a testing card; the light source and the imaging system are arranged at an interval; the test card is arranged on the light emitting side of the light source, and the test card is provided with a light hole; the light emitted by the light source can penetrate through the light-transmitting hole to be collected by the imaging system, and the light-transmitting hole can form a light spot image in the imaging system; and the light spot image can be used for interpreting the blurring degree of the imaging system. According to the testing equipment based on the imaging system, the testing card with the light hole is arranged, and the light emitted by the light source can be collected by the imaging system through the light hole, so that the light hole can form the light spot image on the imaging system, and the light spot image can be used for quantitatively measuring the blurring degree of the imaging system.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Aircraft nose landing gear steering release valve moment test machine

ActiveCN109159918BImprove securityExtended flight timeAircraft components testingControl systemAircraft landing

Aircraft nose landing gear steering release valve torque test machine includes the main body of the test machine equipped with movable universal wheels and brakes, a pressure release valve torque test installation platform, a hydraulic oil circuit control system for testing, a pressure sensing test system, Main parts such as the oil leakage test pipeline of the oil inlet oil circuit, the oil leakage test pipeline for the oil return oil circuit, and the leakage oil liquid collection plate, the overall shape of the aircraft nose landing gear steering release valve moment test machine provided by the present invention The small size makes it very flexible and easy to operate, and the low cost makes it easy to test the nose gear relief valve of the aircraft. At the same time, it is easy to realize the test work of various types of pressure relief valves, thereby improving the efficiency of the aircraft pressure relief valve test operation, realizing quantitative testing, and maximizing the safety of the performance test operation of the aircraft landing gear pressure relief valve. Reduce maintenance time to increase aircraft flight time and increase revenue for airlines.

Owner:HANGCHENG TIANJIN TECH

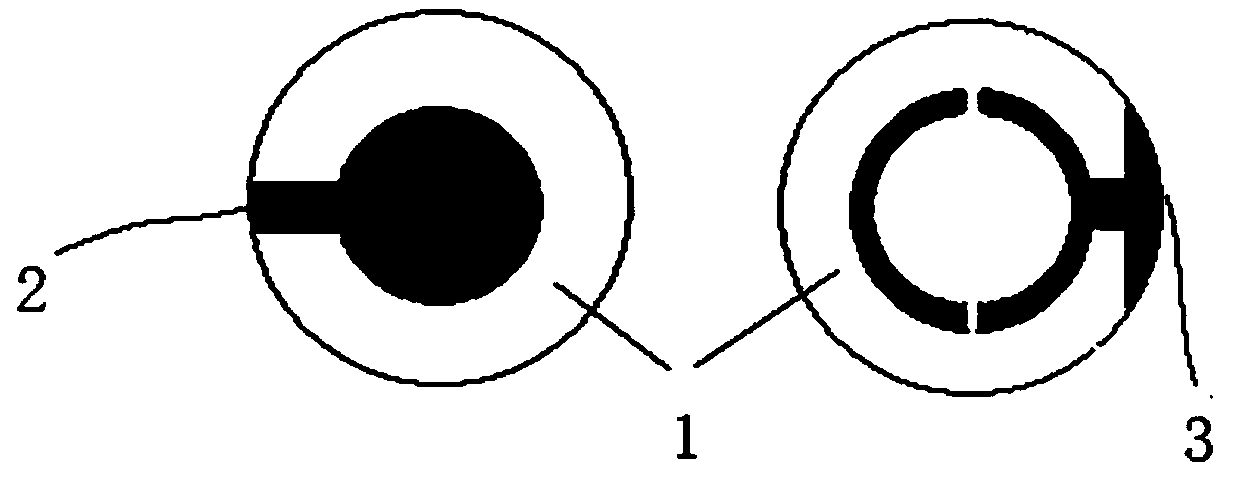

Device and method for testing dynamic friction coefficient of annular surface under dynamic impact

ActiveCN113092362BRealize Quantitative TestingThe method is simple and accurateUsing mechanical meansMaterial analysisFrictional coefficientEngineering

The invention discloses a test device and method for dynamic friction coefficient of an annular surface under dynamic impact, aiming at obtaining accurate friction coefficient. The device of the present invention is composed of a striking rod, a first friction pair, an upper second friction pair, a lower second friction pair, a left support plate, a right support plate, and a dynamic force sensor. The three friction pairs left support plate, right support plate, dynamic The force sensor is mounted coaxially. The test method is to hit the left end face of the first friction pair with the impact rod, and the first friction pair, the upper second friction pair, and the lower second friction pair generate relative motion to generate friction force; the friction force is transmitted to the left support plate, and then the dynamic force The sensor converts it into a voltage signal and measures it, and combines the pressure on the upper second friction pair and the lower second friction pair to calculate the friction coefficient. The device of the invention has the advantages of simple structure, convenient layout, reusability, simple test method and high accuracy, and solves the technical problem that it is difficult to quantitatively test the friction coefficient of the annular surface under dynamic impact.

Owner:NAT UNIV OF DEFENSE TECH

A Calculation Method for Isothermal Compressor Performance Test

ActiveCN112459984BRealize Quantitative TestingHigh precisionPump testingPositive displacement pump componentsCorrelation coefficientComputation process

The invention provides a method for testing and calculating the performance of an isothermal compressor, including: step 1, collecting parameters of the isothermal compressor; step 2, preliminary determination of multiple variables in the calculation process: step 201, obtaining pressure and temperature parameters of the inlet and outlet of each level in the design state ; Step 202, calculate the multi-variables at all levels of the design state: Step 203, initially determine the multi-variables at all levels of the experimental state: make the multi-variables at all levels of the experimental state equal to the multi-variables at all levels of the design state; Step 3, preliminary calculation of test data: Step 4, Data comparison and correlation coefficient selection iterative calculation: compare the whole machine power N meter calculated in step 3 with the measured power N, calculate the relevant power adjustment coefficient, and recalculate the multi-variables at all levels: re-determine the multi-variables at all levels in the test state : Make the multi-variables at all levels of the test state equal to the multi-variables at all levels obtained by recalculation; iterate the calculations of steps 3 and 4; step 5, calculate the relevant characteristic parameters.

Owner:XIAN SHAANGU POWER

Test method and system, and storage medium

ActiveCN111431633BAchieve full coverage testingRealize Quantitative TestingTransmission monitoringWireless communicationTarget signalSignal source

The embodiment of the present application discloses a test method and system, and a storage medium. The test method includes: determining the target signal source; wherein, the target signal source is any frequency band signal corresponding to any standard signal; obtaining configuration information of the terminal to be tested , and generate multiple initial signals corresponding to the target signal source according to the configuration information, so that the terminal under test performs service processing based on multiple initial signals; perform attenuation processing on multiple initial signals, and obtain multiple attenuated signals corresponding to multiple initial signals signal; wherein, an initial signal corresponds to an attenuated signal; when the terminal to be tested performs service processing based on multiple attenuated signals, obtain the switching parameters and service quality parameters corresponding to the terminal to be tested; generate the target according to the switching parameters and the service quality parameters The test result corresponding to the signal source.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

Hot-film gas extinguishing chemical concentration sensing module

The invention discloses a hot-film gas extinguishing chemical concentration sensing module. By the adoption of a diffluence test method, microscale airflow passes through a bypass pipeline, inside which a temperature-sensitive film and a heating film are arranged; the microscale air and a gaseous mixture of the gas extinguishing chemical are heated by the heating film; as the gaseous mixture passes through the temperature-sensitive film, the temperature of the temperature-sensitive film changes and then the resistance value of the temperature-sensitive film changes; voltage value generated from the circuit is outputted, and through signal treatment, a digital signal and an analog signal are outputted. By controlling the flow of gases flowing through the temperature-sensitive film, the temperature change of the temperature-sensitive film is determined by the concentration of the gaseous mixture, and the electric signal generated is processed and outputted so as to obtain the concentration value of the gas extinguishing chemical. The invention can be widely applied in a gas extinguishing chemical concentration test system so as to establish a rapid high-precision gas extinguishing chemical concentration test system.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com