An electrostatic sensor cycle test device

An electrostatic sensor and cyclic testing technology, which is applied to measurement devices, uses electromagnetic/magnetic devices to transmit sensing components, instruments, etc., can solve the quantitative characterization of electrostatic sensor performance, electrostatic sensor induction signals are easily affected by the environment, and hinder the optimization of electrostatic sensors. Design static monitoring system performance and other issues to achieve the effect of saving materials, testing more items, and fully charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Real-time examples of the present invention will be further explained below with the help of related figures. In the drawings, for simplification and convenient labeling, the proportions of shapes may be exaggerated. The implementation methods described below by referring to the figures are exemplary, and are only used to explain the present invention, and should not be construed as limiting the present invention.

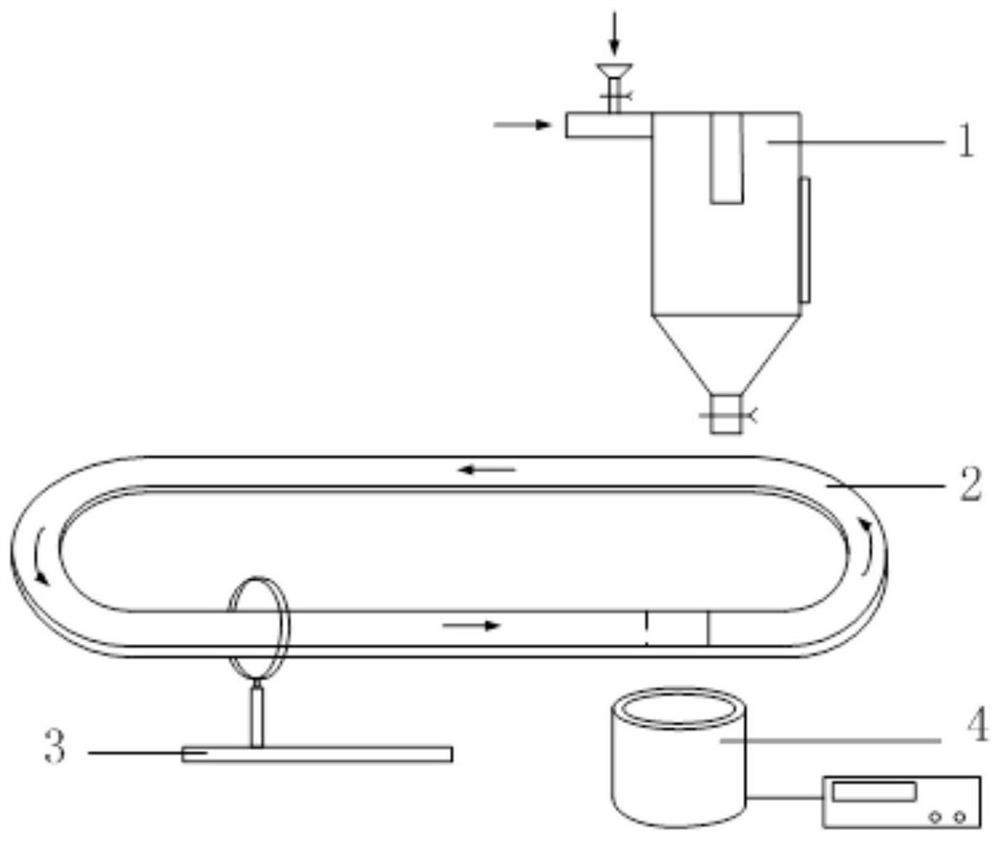

[0026] The present invention proposes an electrostatic sensor cycle testing device, which is used to test the inductive characteristics of electrostatic induction type sensors, such as figure 1 As shown, the device includes an object charging device 1 , an object conveying device 2 , a sensor support positioning device 3 , and an object charge measuring device 4 .

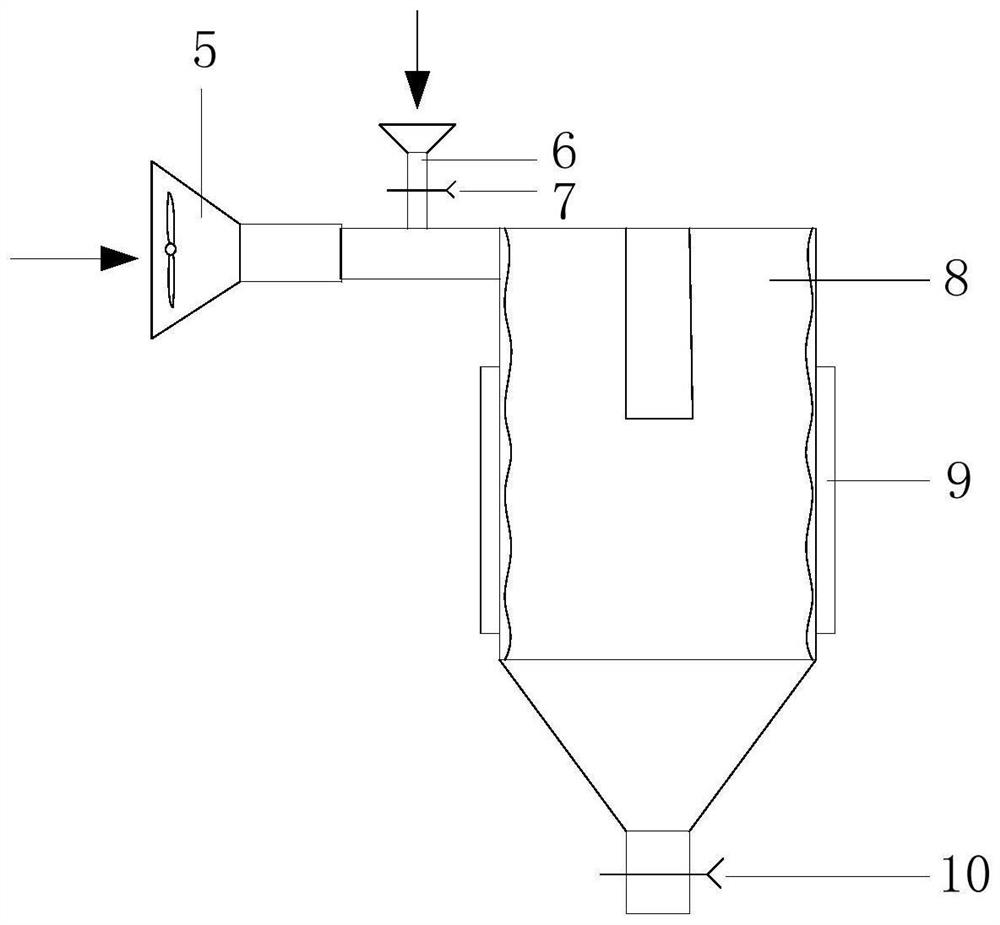

[0027] In this embodiment, the object charging device 1 is arranged above the object conveying device 2 and includes an air blowing device 5 , a delivery device 6 , and an air duct 8 . The air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com