Silicon-based quartz MEMS resonant torque sensor for micro-nano-scale material

A torque sensor and micro-nano-scale technology, applied in the direction of measurement, instruments, and measuring devices that measure the frequency change force of stressed vibration elements, can solve problems such as noise interference, limited precision integration, and no piezoelectric characteristics. Achieve the effects of high precision, improved sensitivity, and high quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

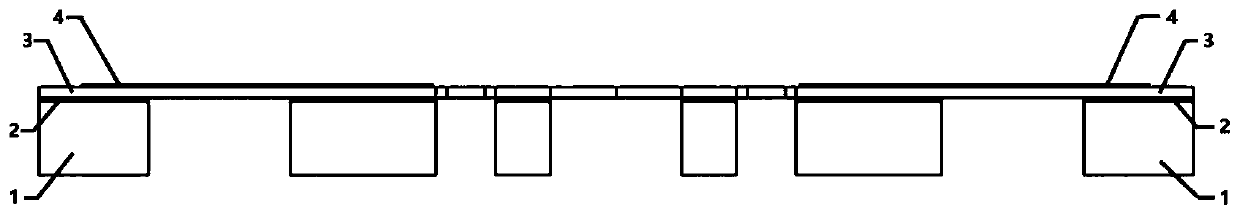

[0026] see figure 1 , a silicon-based quartz MEMS resonant torque sensor for micro-nano-scale materials, comprising a single crystal silicon base layer 1, a silicon dioxide insulating layer 2 grown on the single crystal silicon base layer 1, and a silicon dioxide insulating layer 2 A monocrystalline silicon structural layer 3 is provided, and a quartz double-ended fixed tuning fork 4 is glued on the monocrystalline silicon structural layer 3;

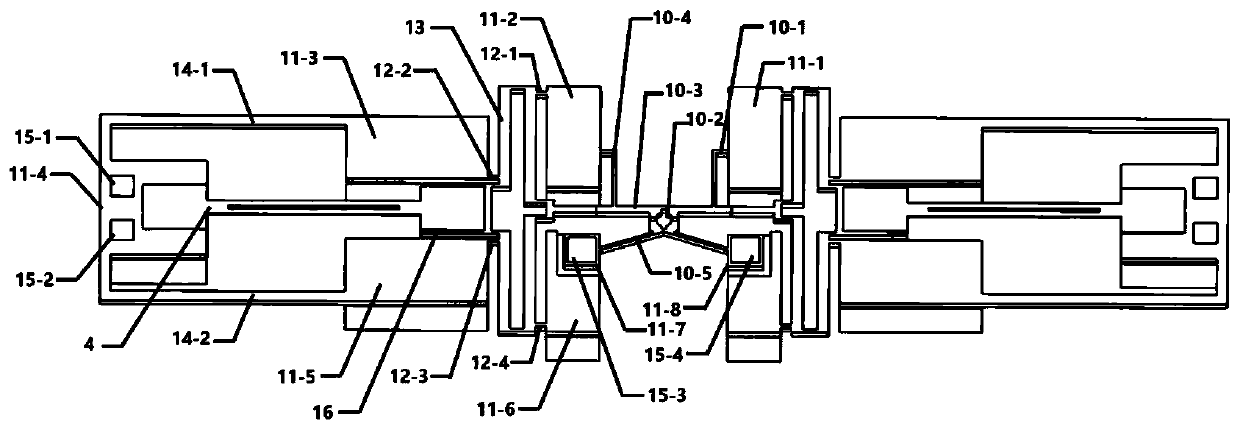

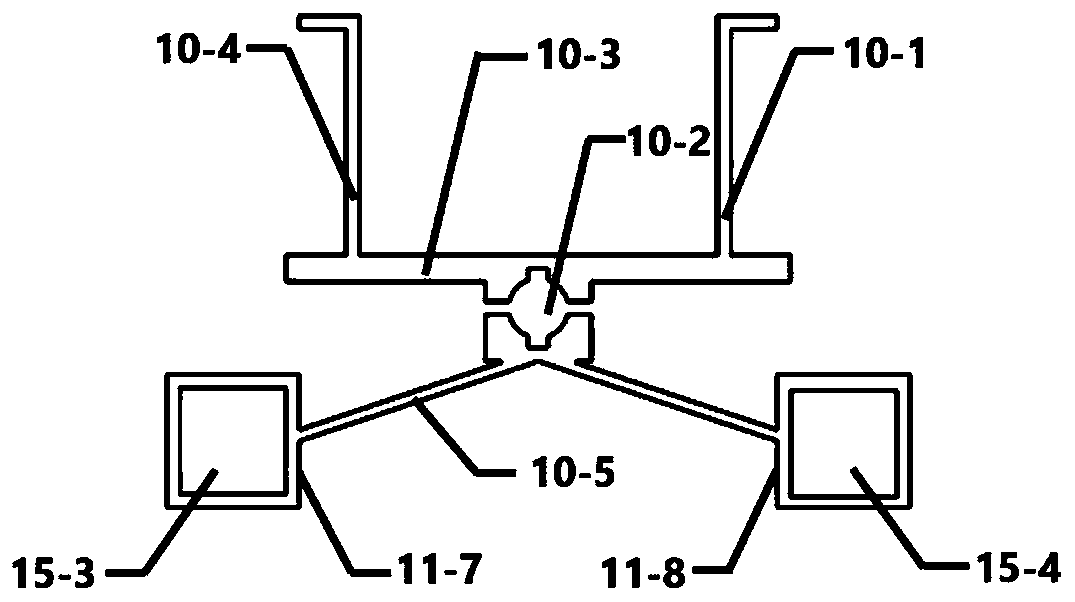

[0027] see figure 2 , image 3 and Figure 4 , the monocrystalline silicon structure layer 3 includes a linear micro-nano material clamping mechanism, and the linear micro-nano material clamping mechanism includes a keyway 10-2, and the keyway 10-2 is used to install a spline 17- at one end of the linear micro-nano material 17- 1. One side of the keyway 10-2 is connected to the middle of the output beam 10-3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com