Hot-film gas extinguishing chemical concentration sensing module

A gas fire extinguishing agent and concentration sensing technology, applied in the field of aircraft fire prevention, can solve the problems of inconvenient operation, easy blockage of porous restrictor plugs, lack of computer data processing means, etc., to improve test accuracy, reduce response lag, improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

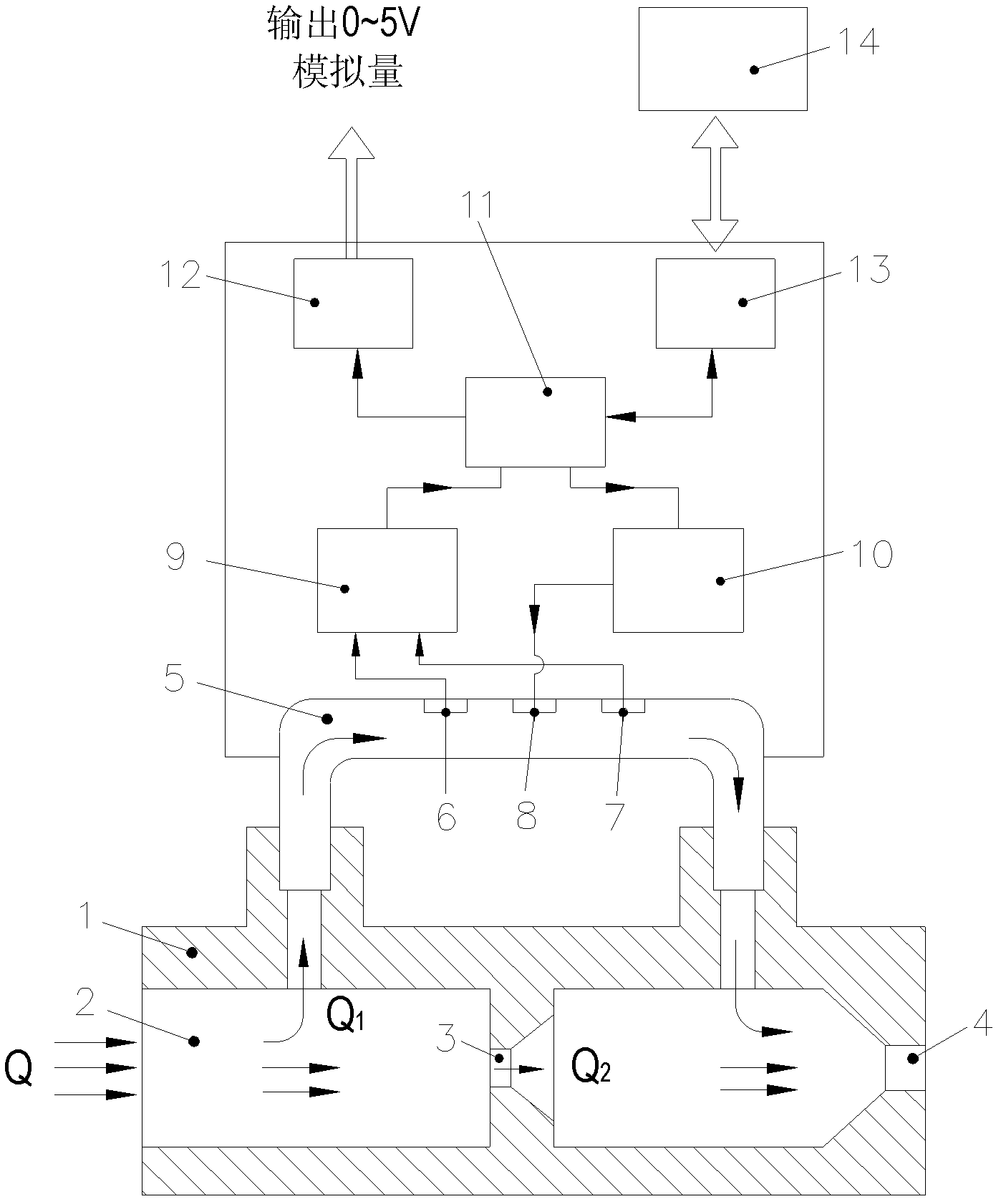

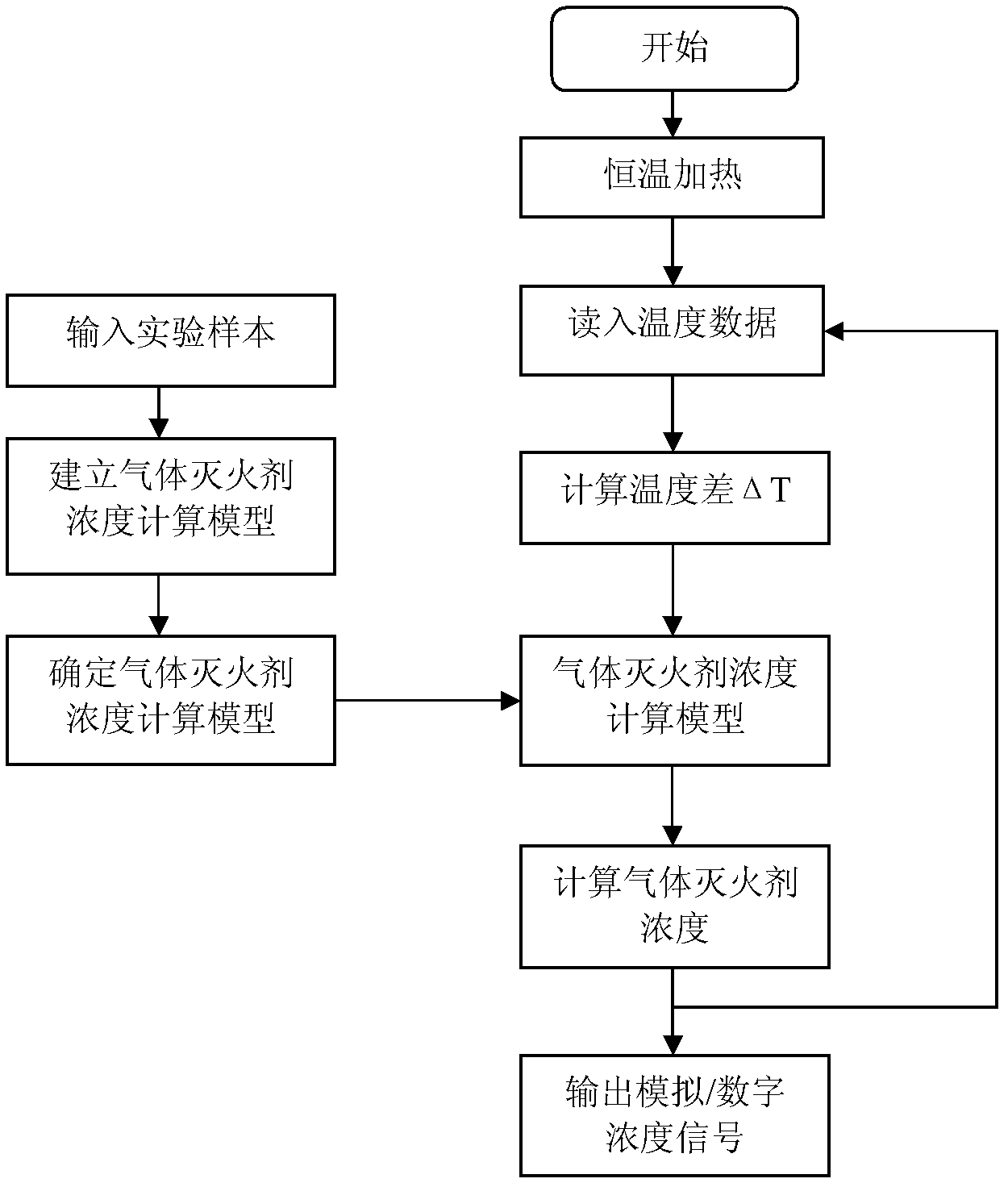

[0025] The hot-film type gas fire extinguishing agent concentration sensing module of this embodiment has a structure such as figure 1 As shown, the gas fire extinguishing agent concentration information sensing component is placed above the main pipeline 2, and the mixed gas of air and gas fire extinguishing agent after corresponding treatment enters the main pipeline 2 of the module at a constant temperature and flow rate, An orifice 3 is added to the path 2, so that a certain pressure difference is formed before and after the orifice 3, so that a small amount of mixed gas to be measured enters the bypass line 5, and two temperature-sensitive films 6, 7 are placed in the bypass line 5 and a heating film 8, the heating film 8 heats the mixed gas to be measured flowing through the bypass pipeline 5, and the temperature-sensitive films 6 and 7 detect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com