Unsaturated bentonite corrosion test system and method in multi-field coupling environment

A test system and bentonite technology, applied in the field of geotechnical test equipment, can solve the problems of lack of proof of corrosion test and high requirements, and achieve the effect of widening the scope of application, stabilizing water flow, and reducing the influence of human operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

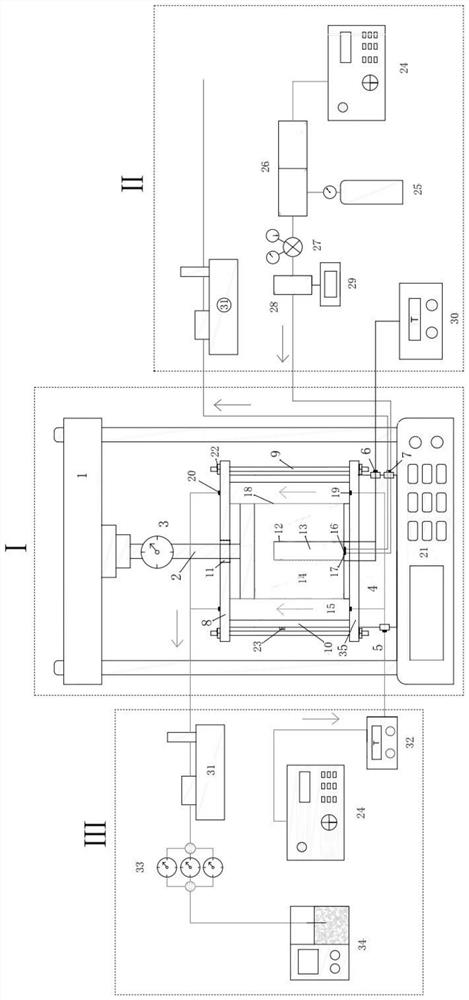

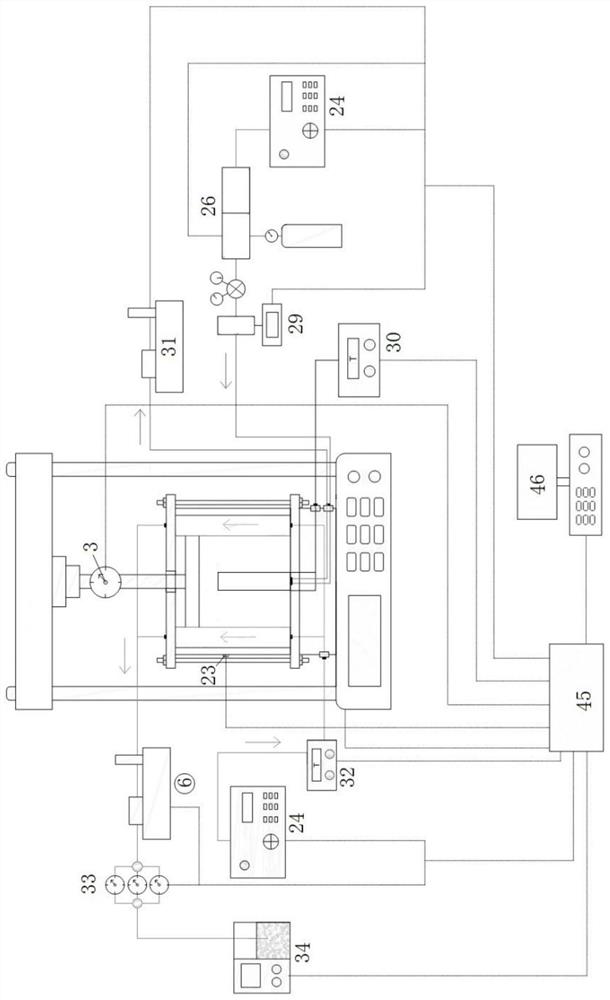

[0056] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

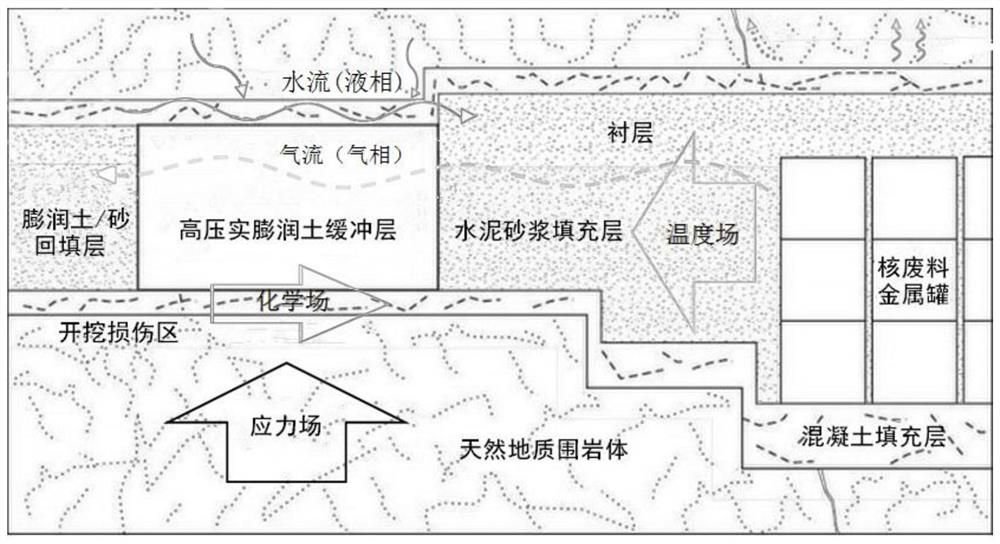

[0057] In the deep geological repository of high-level radioactive waste, the bentonite buffer / backfill layer is subject to the coupling effects of temperature field, humidity field, chemical field and stress field, such as figure 1 shown. The surface of the bentonite is in contact with groundwater, and the groundwater slowly soaks into the bentonite cushion; the interior of the bentonite is in an unsaturated state, and under the action of the groundwater solution, a saturation gradient is formed from the surface of the bentonite to the interior of the bentonite. During the tens of thousands of years of operation of the repository, the gases (methane, hydrogen, carbon dioxide, etc.) The constant climb endangers the safety of the repository. Real-time testing of the microscopic evolution and macroscopic response of unsaturated bentonite diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com