A Quantitative Test Method for the Whole Process of Damage Evolution in Vibration Fatigue Test

A technology of vibration fatigue and damage evolution, which is applied in vibration testing, testing of machine/structural components, testing material strength by applying repetitive force/pulsation force, etc. , large image scale and other issues, to achieve the effect of low test equipment requirements, great reference significance, and high data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

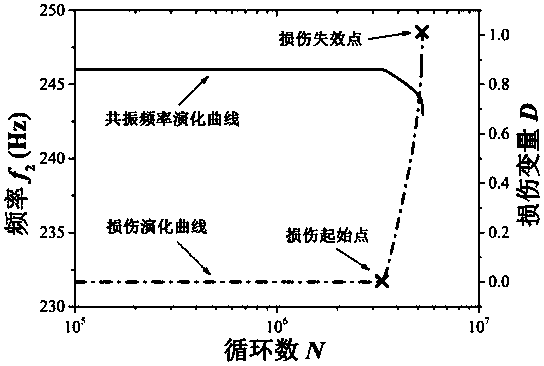

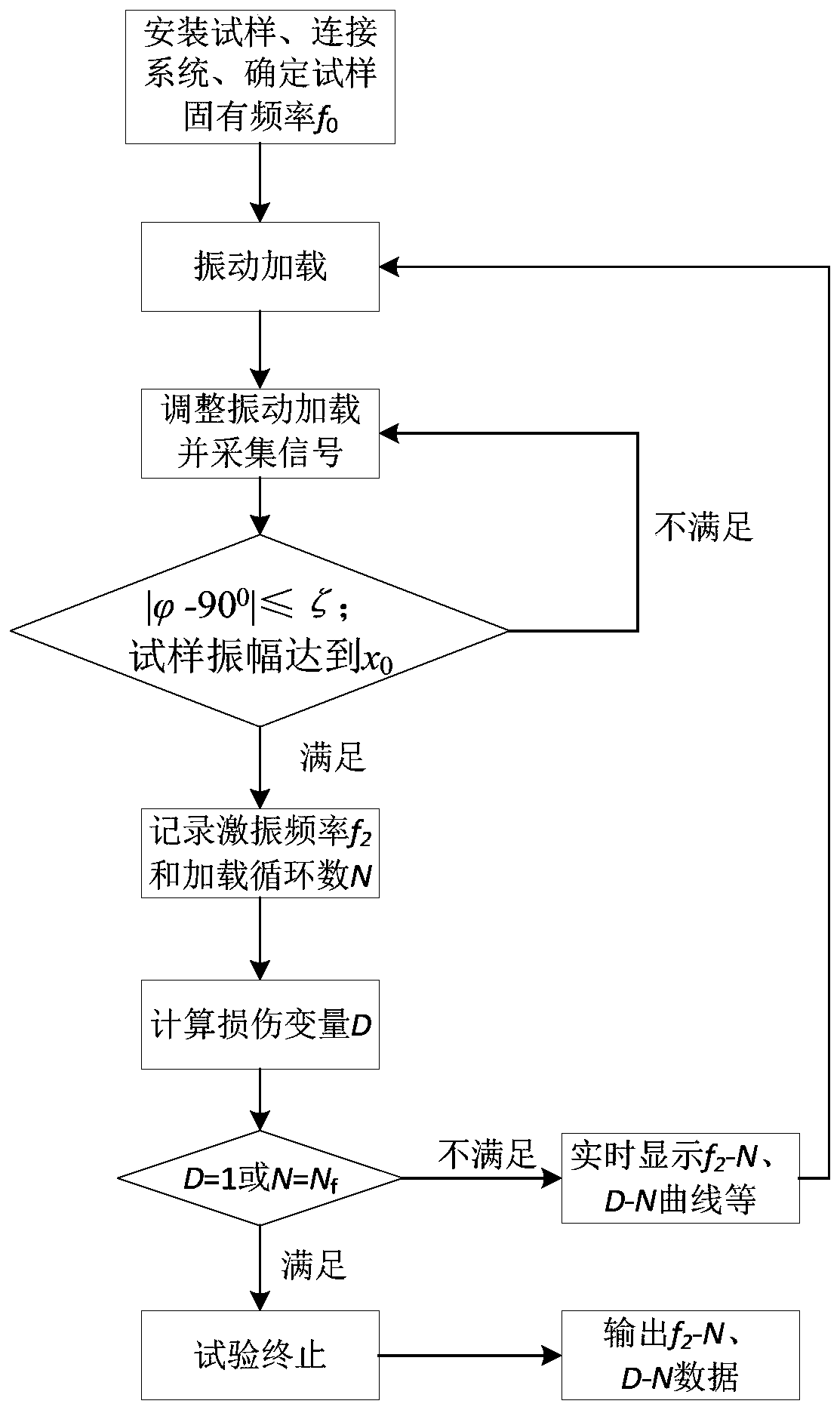

[0045] See attached figure 1 As shown, the steps of the quantitative test method for the whole process of damage evolution in this kind of vibration fatigue test are as follows:

[0046] Step 1. Prepare samples according to the aviation standard "Engine Blade and Material Vibration Fatigue Test Method" (HB5277-1984);

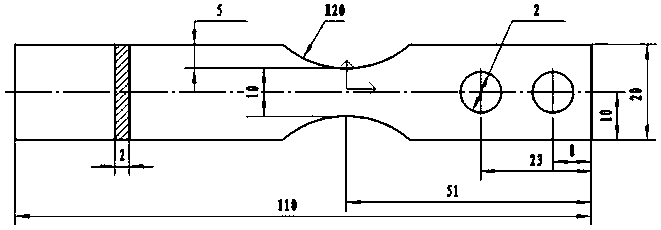

[0047] The sample is made of TA11 titanium alloy plate with a thickness of 2mm. The length of the sample is 120mm and the width is 20mm. The minimum width of the dangerous section is 10mm. For the shape and size of the sample, see figure 2 . After actual measurement, the initial natural frequency f of the sample is determined 0 246Hz, the maximum number of cycles N f for 10 7 Weekly, the specified maximum test stress value is 440MPa, after stress calibration, the specified value of the sample amplitude is determined to be 2.505mm;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com