Sample preparation method suitable for hard alloy cobalt phase structure X-ray diffraction method test

A cemented carbide and X-ray technology, which is applied in the field of cemented carbide material detection, can solve the problems affecting the measurement accuracy and achieve the effect of quantitative testing, eliminating the need for instrument condition selection tests, and simple configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

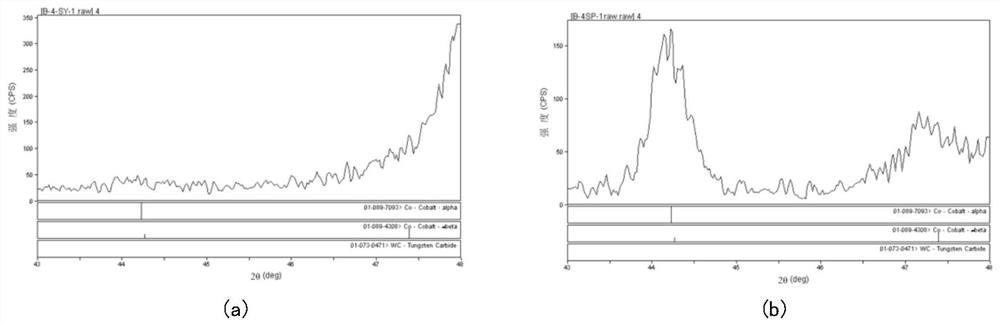

[0030] In this embodiment, the cobalt phase structure analysis is performed on the large product cemented carbide, so the large product cemented carbide needs to be cut first. The sample preparation method suitable for the X-ray diffraction test of the cobalt phase structure of the cemented carbide provided in this embodiment includes the following steps:

[0031]S1. Cutting: Use a diamond cutting machine or wire cutting to cut the cemented carbide samples of large products to obtain cemented carbide samples. The size of the prepared samples is 20mm × 20mm × 10mm.

[0032] S2. Select the test surface: use any plane of the cemented carbide sample as the test surface;

[0033] S3. Corrosion

[0034] S31. Preparation of corrosion solution

[0035] (1) preparation of potassium ferricyanide solution: take by weighing 200g potassium ferricyanide and dissolve it in 1000mL distilled water, mix well, and load it into a 1000mL brown reagent bottle for subsequent use;

[0036] (2) Pre...

Embodiment 2

[0042] In this embodiment, the cobalt phase structure analysis is performed on the large product cemented carbide, so the large product cemented carbide needs to be cut first. The sample preparation method suitable for the X-ray diffraction test of the cobalt phase structure of the cemented carbide provided in this embodiment includes the following steps:

[0043] S1. Cutting: Use a diamond cutting machine or wire cutting to cut the cemented carbide samples of large products to obtain cemented carbide samples. The size of the prepared samples is 20mm × 20mm × 10mm.

[0044] S2. Select the test surface: use any plane of the cemented carbide sample as the test surface;

[0045] S3. Corrosion

[0046] S31. Preparation of corrosion solution

[0047] (1) preparation of potassium ferricyanide solution: take by weighing 100g potassium ferricyanide and dissolve it in 1000mL distilled water, mix, and load it into a 1000mL brown reagent bottle for subsequent use;

[0048] (2) Prepara...

Embodiment 3

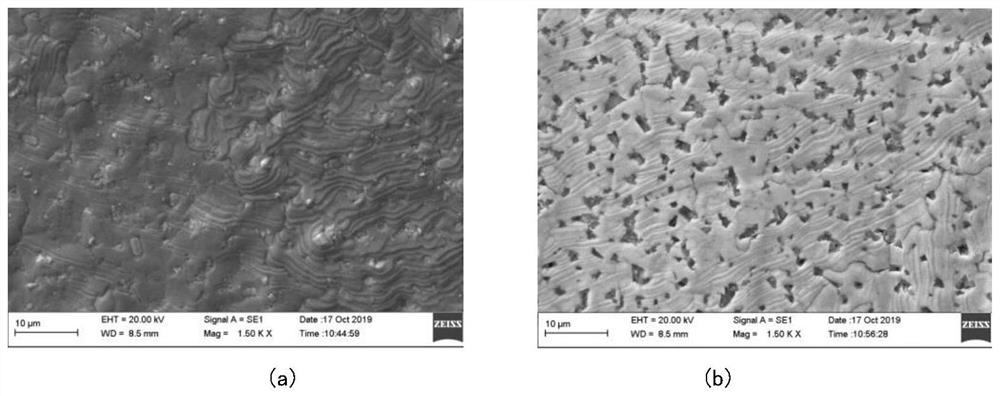

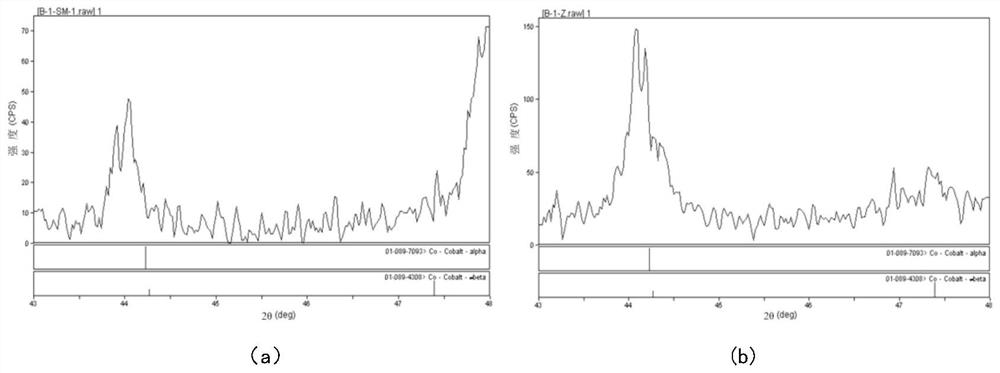

[0068] In this embodiment, the surface grinding of a surface cobalt-rich alloy product is carried out, and the samples before and after grinding are subjected to X-ray diffraction qualitative scanning and X-ray fluorescence spectrum quantitative test to test the cemented carbide sample test. before and after face grinding.

[0069] Qualitative scanning of X-ray diffraction shows that the cobalt phase structure of the alloy surface before grinding contains two phases of α-Co and β-Co, and the surface of the alloy after grinding has only α-Co single phase, and the cobalt phase structure changes from two phases to single phase Mutually.

[0070] The test results of X-ray fluorescence spectroscopy are shown in Table 1.

[0071] Table 1 X-ray fluorescence spectrum test results

[0072]

[0073] It can be seen from Table 1 that the content of cobalt on the surface of the alloy product rich in cobalt is significantly reduced after grinding, which affects the accurate qualitative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com