Compacting mechanism for packaging bags

A packaging bag and solid board technology, applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve problems such as affecting the environment, potential safety hazards for operators, and troublesome operation of packaging bags, achieving good results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

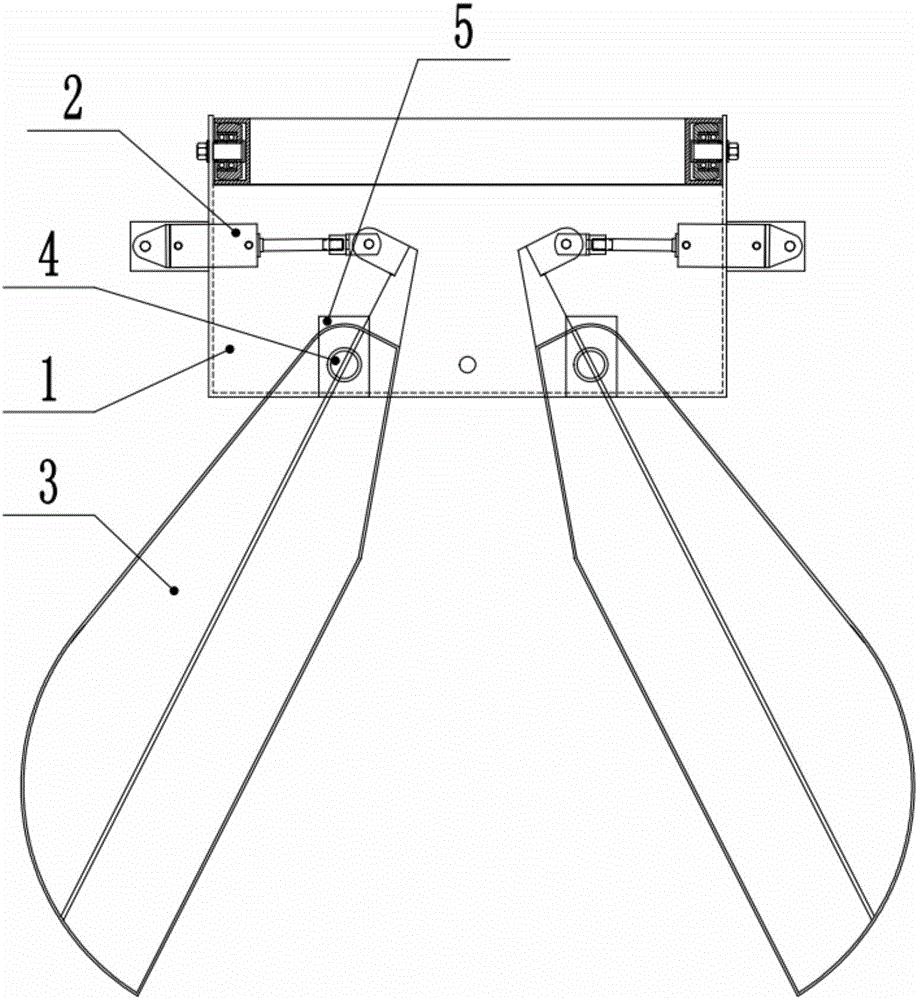

[0011] like figure 1 As shown, the clapping mechanism of the packaging bag in this embodiment includes a frame plate 1, a horizontally arranged push cylinder 2 symmetrically installed on the frame plate 1, and the inner end of the push cylinder 2 is hinged to the upper end of the clap plate 3 , the top of the clapping plate 3 is slidably installed in the chute 5 on the frame plate 1 through the hinge shaft 4 . During use, push the cylinder 2 to push the clapping plate 3 to rotate around the hinge shaft 4, and slide in the chute 5, so as to realize clapping the up and down positions of the packaging bag.

[0012] The above examples are preferred implementations of the present invention, and are only used to illustrate the present invention conveniently, and are not intended to limit the present invention in any form. Anyone with ordinary kno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com