Integrated engineering anchor pole strain gauge measuring and reading device

A technology of anchor rod stress gauge and strain gauge, which is applied in the direction of measuring devices, measuring force, instruments, etc., can solve the problems of troublesome data measurement and reading, a lot of time wasted, and waste of manpower and material resources, so as to save manpower and material resources and facilitate single-person operation , time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The integrated engineering bolt stress gauge measuring and reading device of the present invention will be described in further detail below with reference to the accompanying drawings.

[0019] see Attachment.

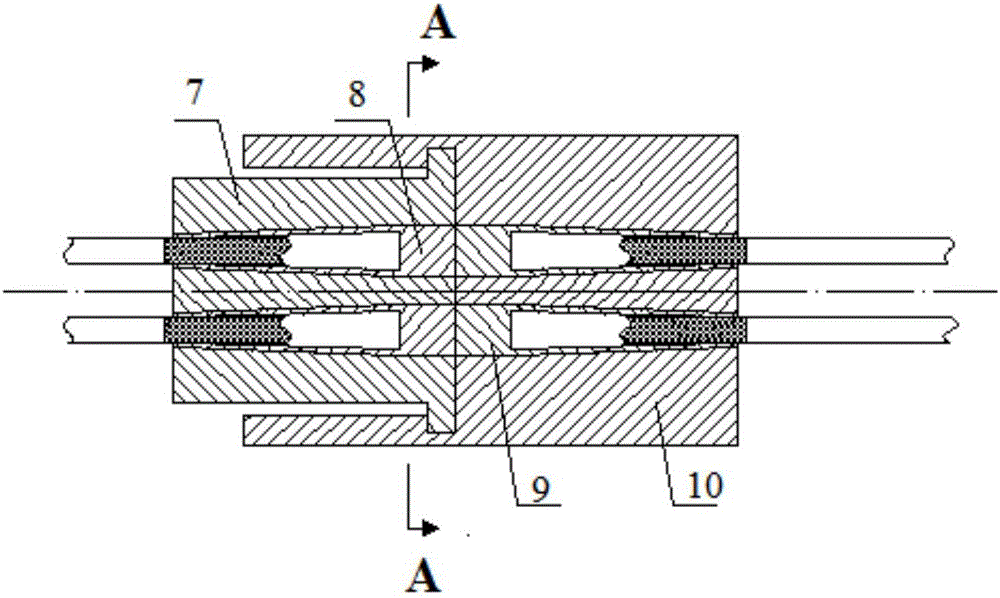

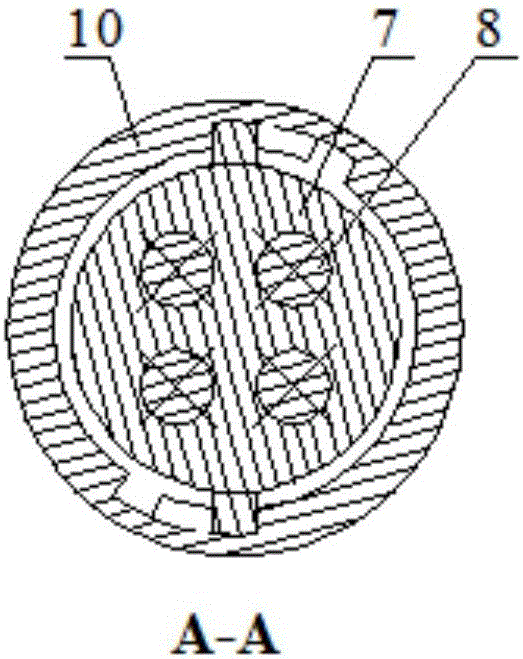

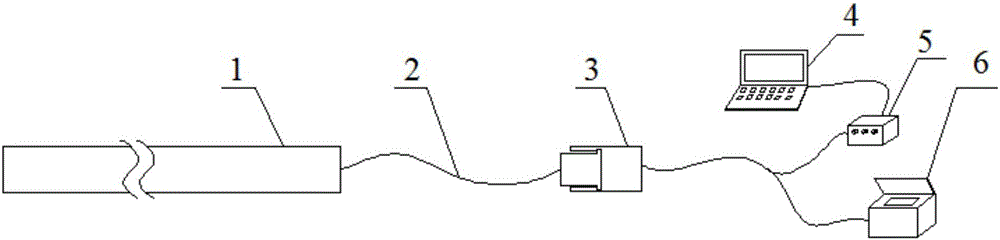

[0020] The integrated engineering bolt stress gauge measuring and reading device is composed of bolt stress gauge 1, stress gauge manual measuring and reading box 6, stress gauge automatic data acquisition box 5 and measuring and reading conversion device 3. A measurement and reading conversion device 3 is arranged between the manual measurement and reading box 6 of the gauge and the automatic data acquisition box 5 of the stress gauge. The ferrule 9 is composed of a measuring and reading line installation head 10. The connection head 7 is provided with four through holes which are parallel to each other along the direction of the central axis. The bottom of the connection head 7 is provided with a boss, and the connection signal line ferrule 8 It is located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com