Vacuum booster detector at the push rod position

A vacuum booster and detection device technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of reduced sealing performance and easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

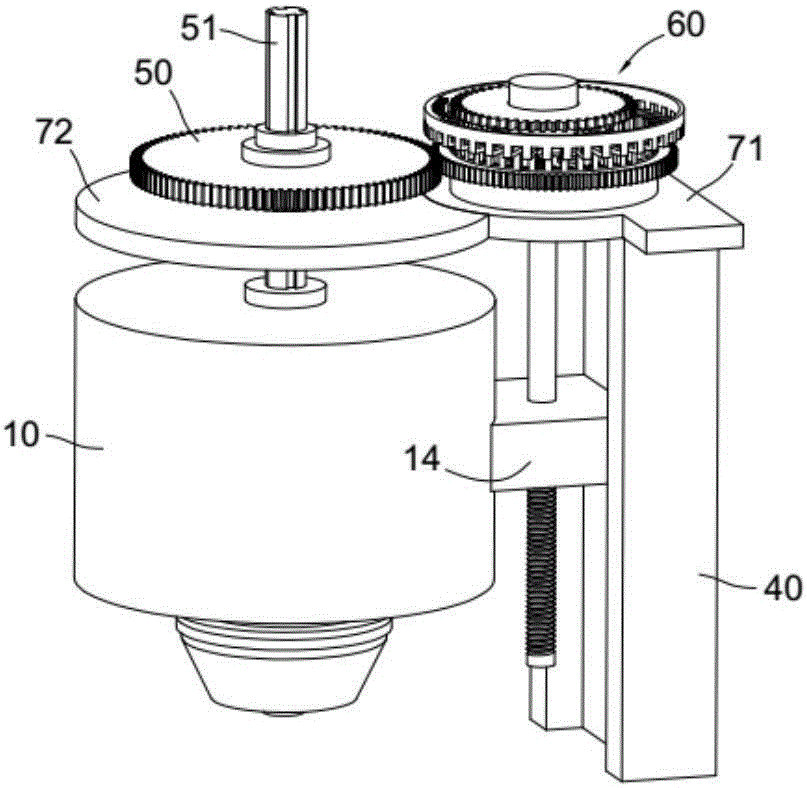

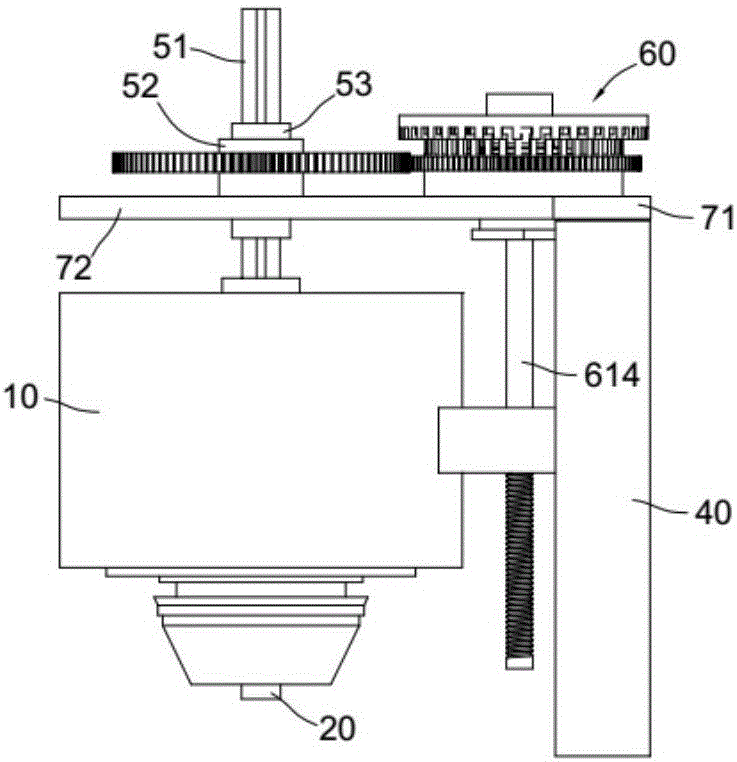

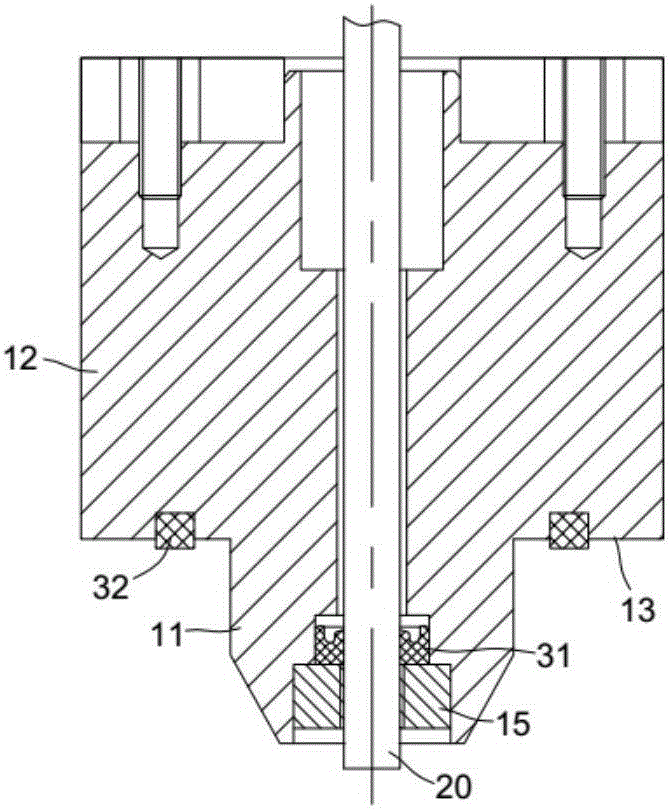

[0046] The following specific implementation refers to Figure 1 to Figure 8 .

[0047] A device for detecting the position of a push rod of a vacuum booster includes an indenter 10, the indenter includes an indenter convex portion 11 inserted into the vacuum booster, and an indenter shoulder 13 is provided between the indenter convex portion and the indenter body 12; An ejector rod 20 is inserted into the indenter, the ejector rod penetrates the indenter, and a first sealing ring 31 is provided between the contact surface of the ejector and the indenter; a second sealing ring 32 is provided on the shoulder of the indenter; The indenter is slidably fitted on the linear slide rail 40, and the linear slide rail is provided with a driving mechanism 60 that drives the indenter to move along the linear slide rail for a fixed displacement.

[0048] The driving mechanism 60 includes a rotating assembly 61, a locking assembly 62 and a driving assembly 63.

[0049] In the driving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com