Automatic Laying and Forming Method of Composite Connecting Skirt

A technology of composite materials and molding methods, which is applied in household appliances, other household appliances, household components, etc., can solve problems such as difficulty in guaranteeing the quality of end surface wire laying, difficulty in connecting skirts, and difficulty in completing the transition of connecting skirts in laying heads, etc., to achieve shortening The effect of production cycle, precise skirt size, and smooth product surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

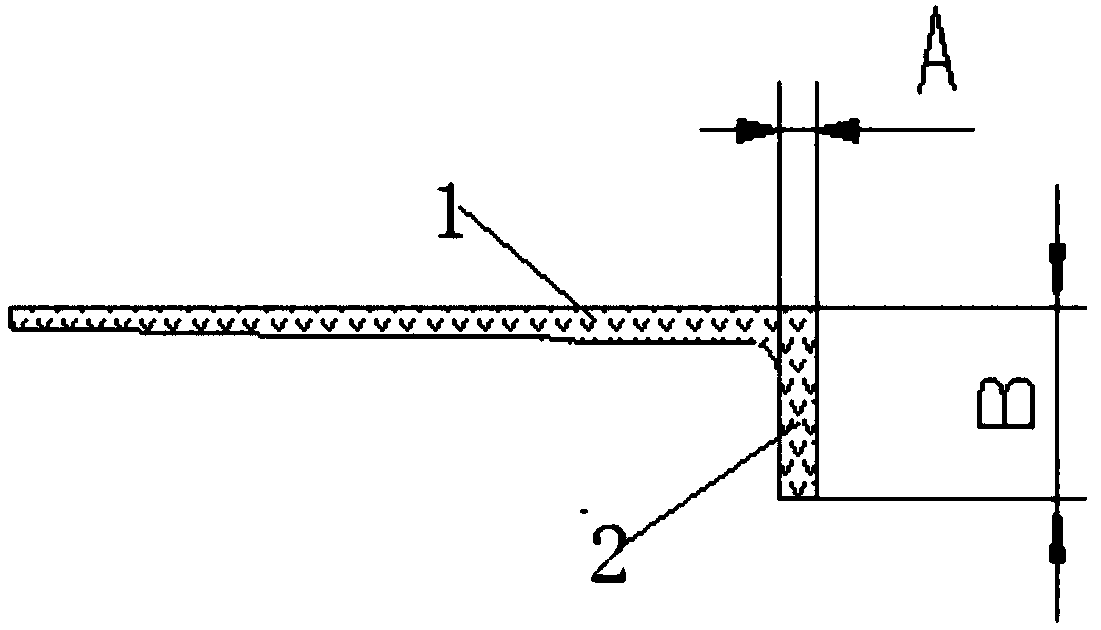

[0035] Such as figure 1 As shown, the composite material connecting skirt includes annulus 1 and end surface 2, A is the thickness of the end surface, and B is the height of the end surface. The specific size requirements are shown in Table 1 below:

[0036] Table 1

[0037] End face diameter / end face height

Φ1200±0.5mm

End Wall Thickness / End Thickness

6.0±0.3mm

Skirt height

250±0.5mm

quality

15kg

Axial load

≥60 tons

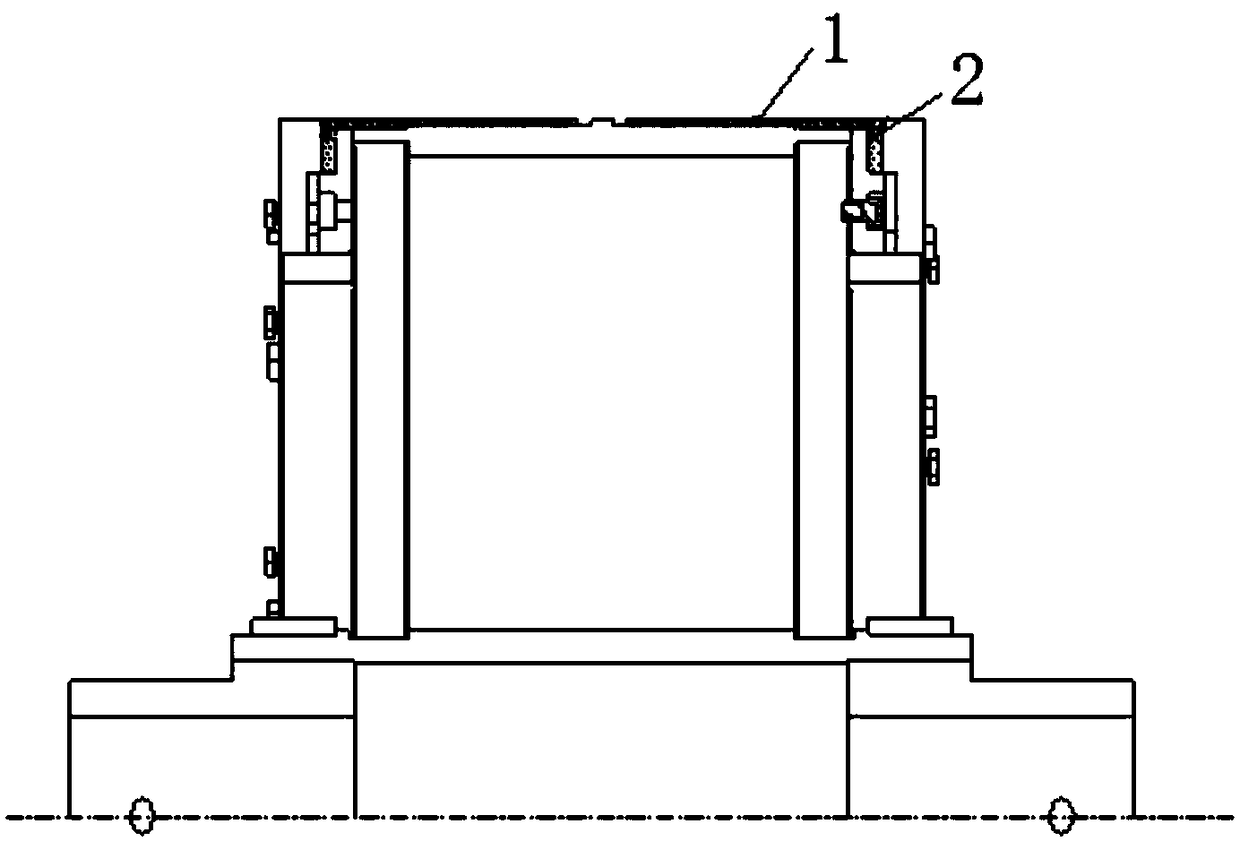

[0038] 1) Forming mold preparation: such as figure 2 As shown, the molds corresponding to the ring surface 1 and the end surface 2 are combined and installed, the surface of the mold is cleaned, and a thin layer of polytetrafluoroethylene tape is wound on the surface (the molding mold is an existing conventional mold).

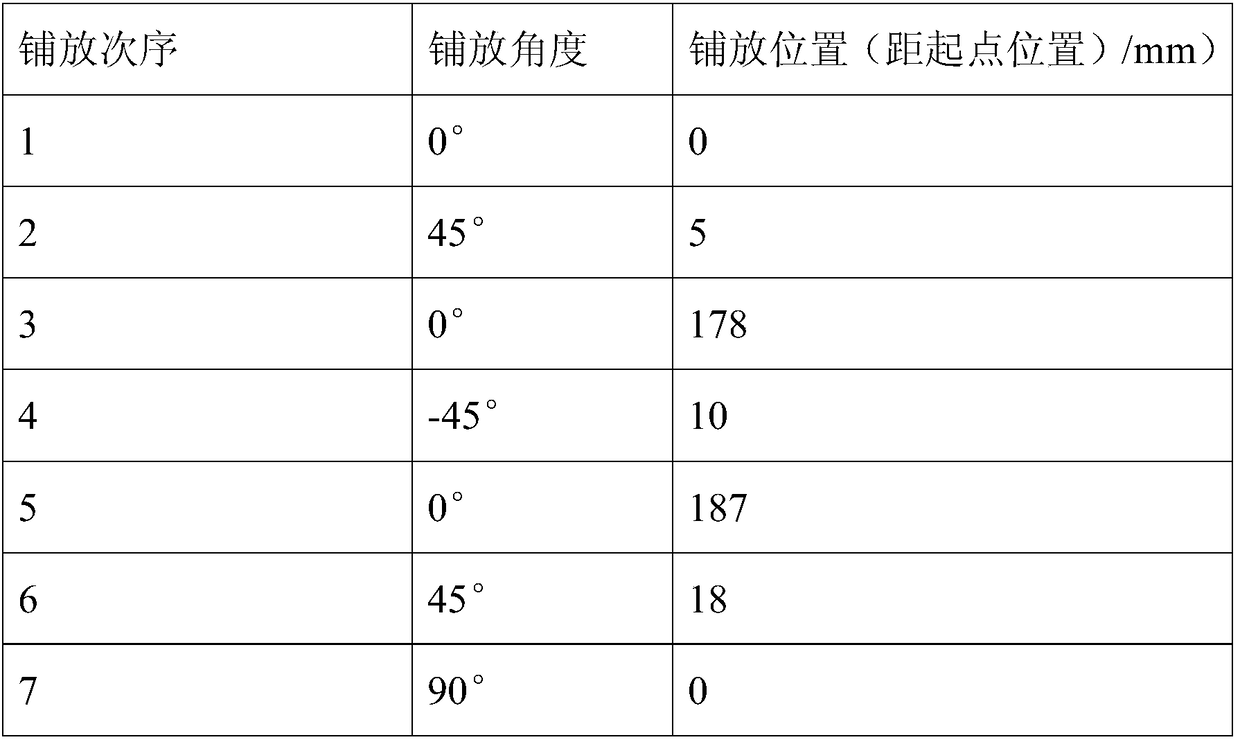

[0039] 2) According to the aforementioned load, quality and size requirements, design 20 layers of layup, the layup angle, order and position are shown in Table 2 below, and use th...

Embodiment 2

[0053] The structure and size requirements of the composite connecting skirt are shown in Table 3 below:

[0054] table 3

[0055] End diameter

Φ1100±0.5mm

End wall thickness

7.2±0.3mm

Skirt height

300±0.5mm

quality

≤20kg

Axial load

≥50 tons

[0056] 1) Forming mold preparation: install the mold assembly, clean the surface of the mold, and wind a thin layer of polytetrafluoroethylene tape on the surface.

[0057] 2) According to the aforementioned load, quality and size requirements, design 24 layers of layup, the layup angle, order and position are shown in Table 4 below, and use the hot-melt method to make carbon fiber prepreg, and the prepreg is T700 carbon fiber + epoxy resin system:

[0058] Table 4

[0059]

[0060]

[0061] 3) Carry out automatic wire laying according to the laying angle, position and sequence in Table 1, and all laying layers of the composite material connecting skirt are divided in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com