Method for removing a blind rivet element from a riveting machine

A technology for blind rivets and connecting components, applied in the field of removing blind rivet components from riveting equipment, which can solve the problems of time-consuming, blind rivet component riveting equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

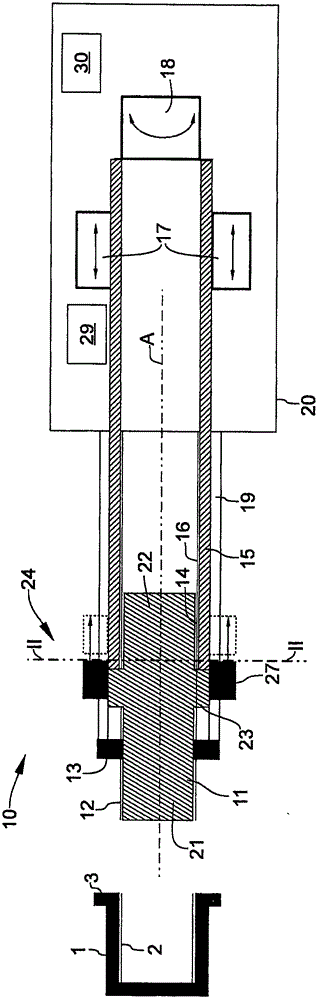

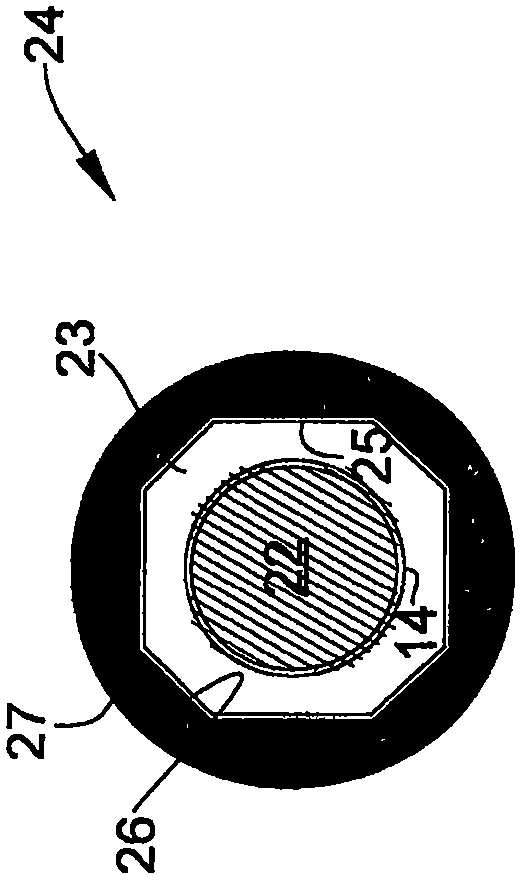

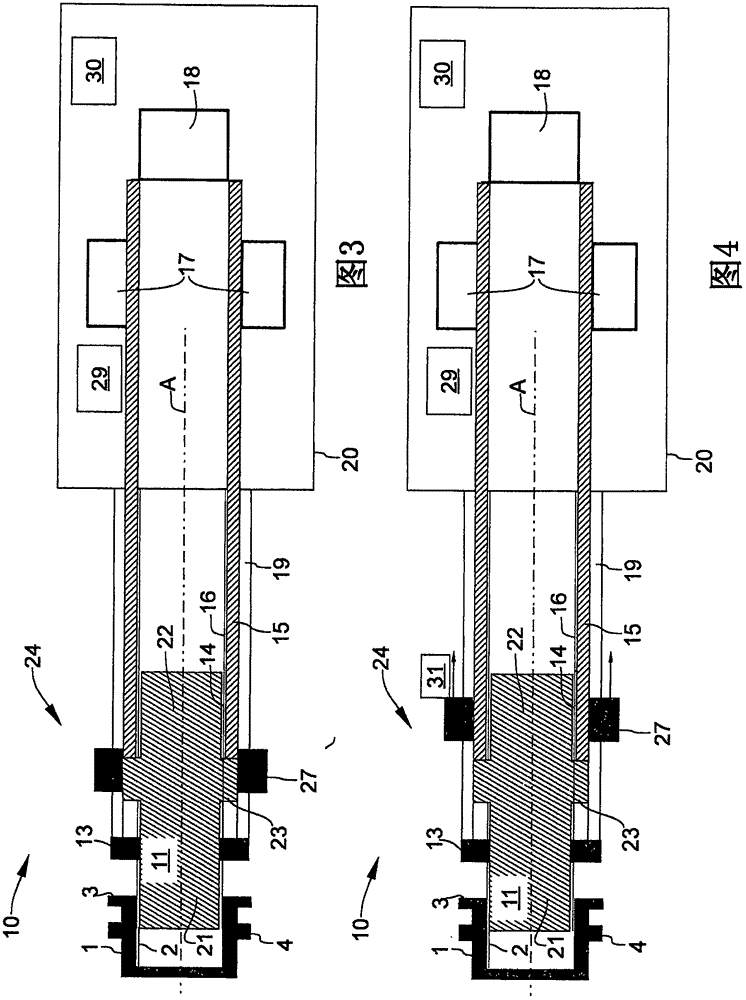

[0023] figure 1 A riveting device 10 designed to implement the method of the invention is shown. The riveting device 10 comprises a housing 20 in which a schematically indicated longitudinal drive 17 and a schematically indicated rotary drive 18 are arranged. The two drives 17 and 18 can be implemented as described in DE 10 2013 105 703 A1. In this case, the longitudinal drive 17 serves to drive the connecting element 15 along its axis of rotation A relative to the housing 20 . The rotary drive 18 serves to rotate the connecting element 15 about its axis of rotation A relative to the housing 20 .

[0024] The connecting element 15 is realized in the form of a sleeve and is mounted in the housing 20 in an axially displaceable and rotatable manner. One end of the connecting element 15 protrudes from the housing and is characterized by a second internal thread 16 in the form of a left-hand thread on its inner circumferential surface. The mandrel 11 is screwed into the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com