Damping connection structure for fire wheel

A vibrating connection, hot wheel technology, applied in the direction of roller skates, skateboards, skating, etc., can solve the problems of lack of firmness, no protective structure, discomfort in the user's legs, etc., to achieve the effect of improving sports experience, simple structure, Ease of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

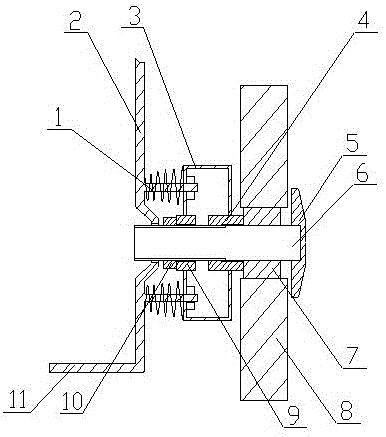

[0014] A vibration-damping connection structure for hot wheels of the present invention is realized in this way. When in use, both feet step on the pedal (11), and the legs are attached to the supporting part (2). When sliding, the pedals facing the ground, there will be a side pressure on the supporting part (2), and the supporting part (2) will press the two damping parts (1) sideways, and the two fixed shafts will slide along the frame part (3) respectively, The compression springs on the two fixed shafts are compressed to consume a certain amount of vibration force for vibration reduction. The bearing (7) is designed between the moving wheel (8) and the rotating shaft (6), which can prevent the moving wheel ( 8) When rotating, it drives the shaft (6) to rotate, and the design of one end of the support sleeve (4) in contact with the bearing (7) can fix the bearing (7), and the inner wall of the other end of the support sleeve (4) is set The threaded design enables the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com