A Rigid Wall Air Bearing Eccentric Compression Rod

A technology of eccentric compression and rods, which is applied in the direction of long-strip structural components, building components, girders, etc. for load-bearing, can solve the problems of restricting the application of high-strength materials and not being able to transmit pressure well, and achieve a good market Application prospect, improvement of overall and local stability, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

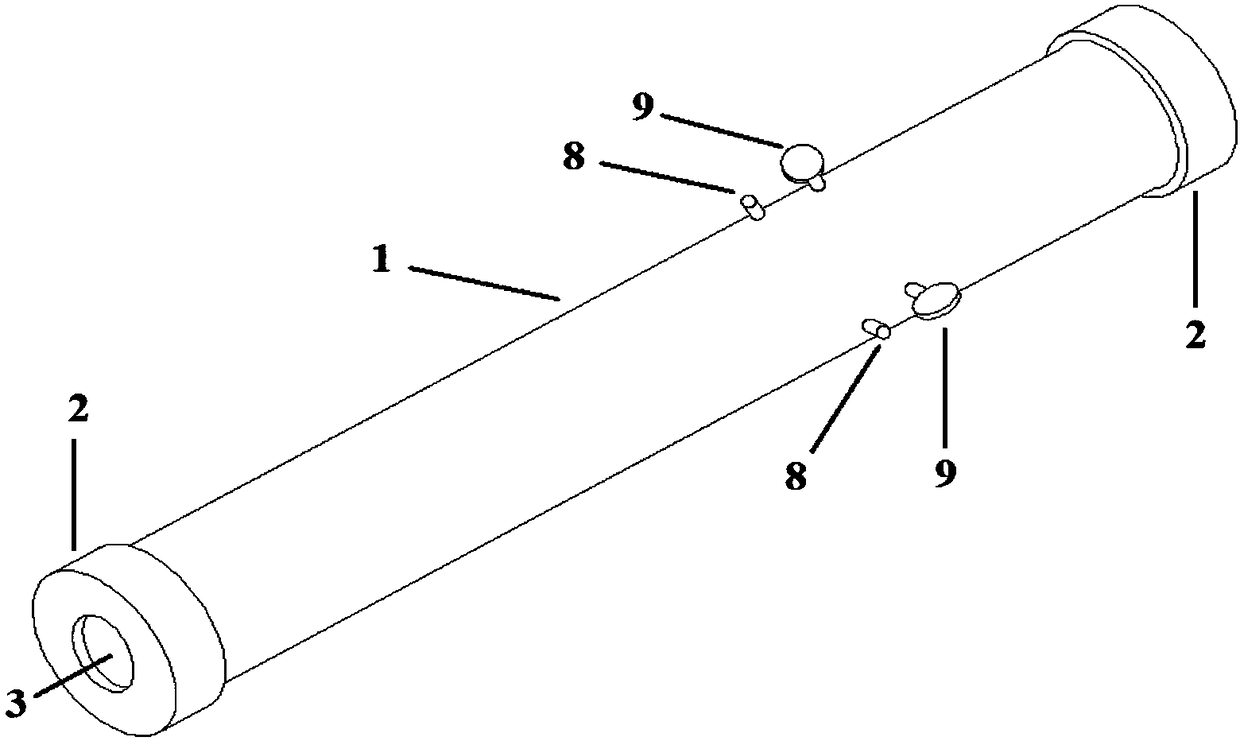

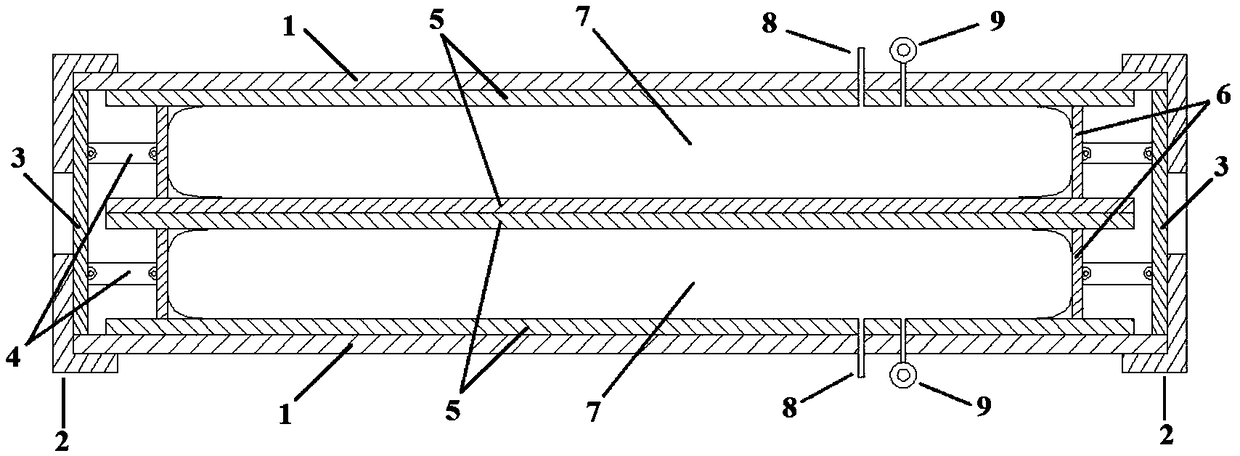

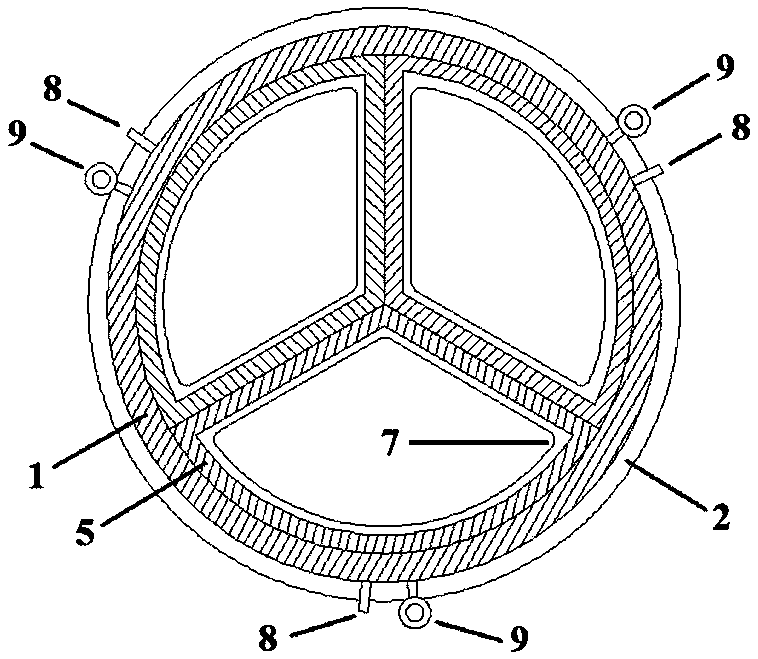

[0029] The present invention adopts the following technical implementation schemes: see Figure 1-3 , consisting of circular rigid tube 1 (see Figure 4 ), screw cap 2 (see Figure 7 ), circular support plate 3 (see Figure 8 ), dowel bar 4, fan-shaped rigid tube 5 (see Figure 5 ), fan-shaped support plate 6 (see Image 6 ), airbag 7 (see Figure 9 ), inflation valve 8, barometer 9, barometer communicating hole 10.

[0030] The circular rigid tube is a hollow tube with high material strength, and the outer walls at both ends are threaded, and 3 airbag inflation holes and 3 barometer communication holes are reserved on the rigid wall, and 3 airbag inflation holes The communication holes of the airbag and the three barometers are evenly distributed on two circumferences respectively. The air bag inflation holes and the communication holes of the barometer co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com