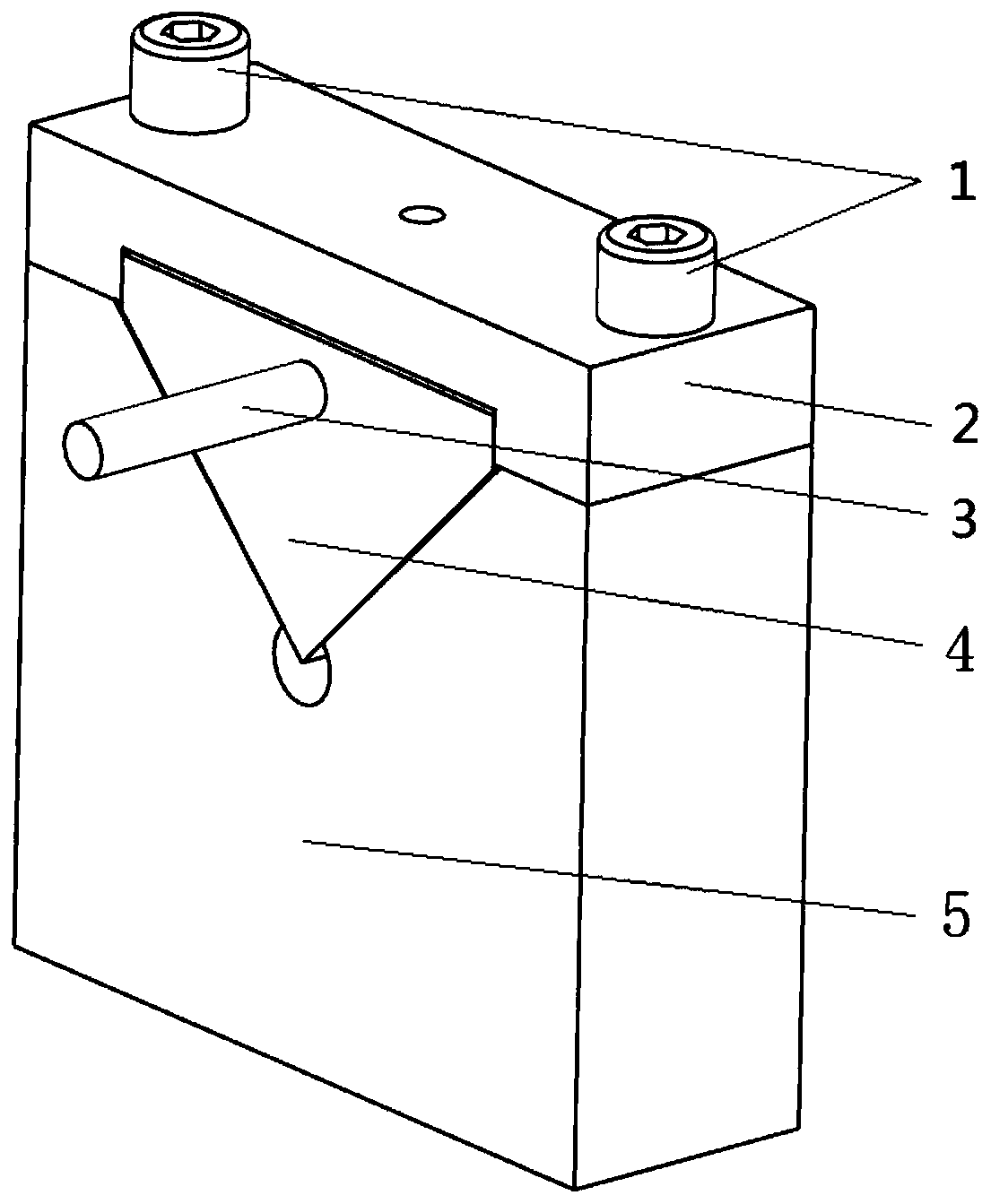

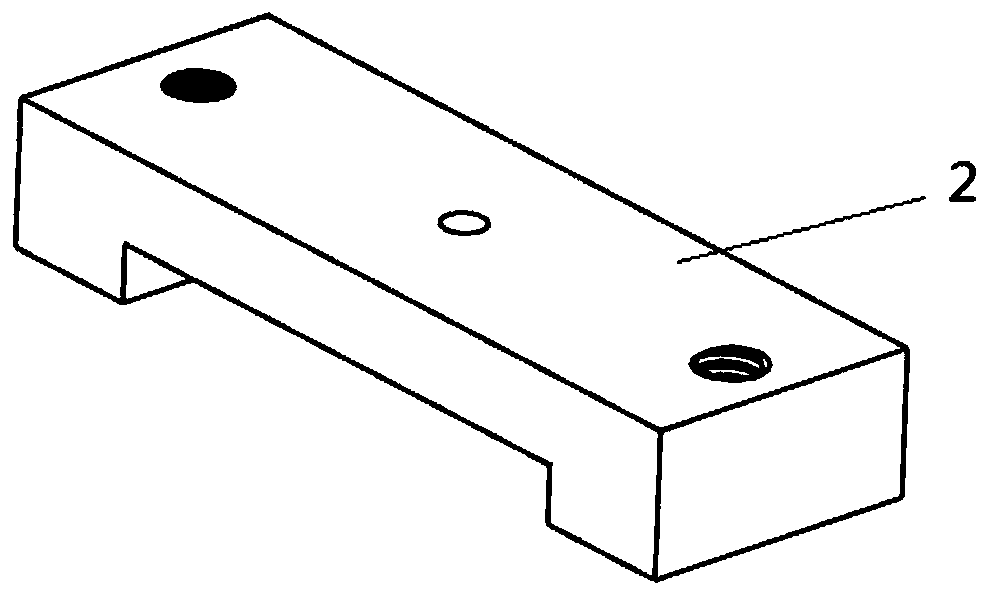

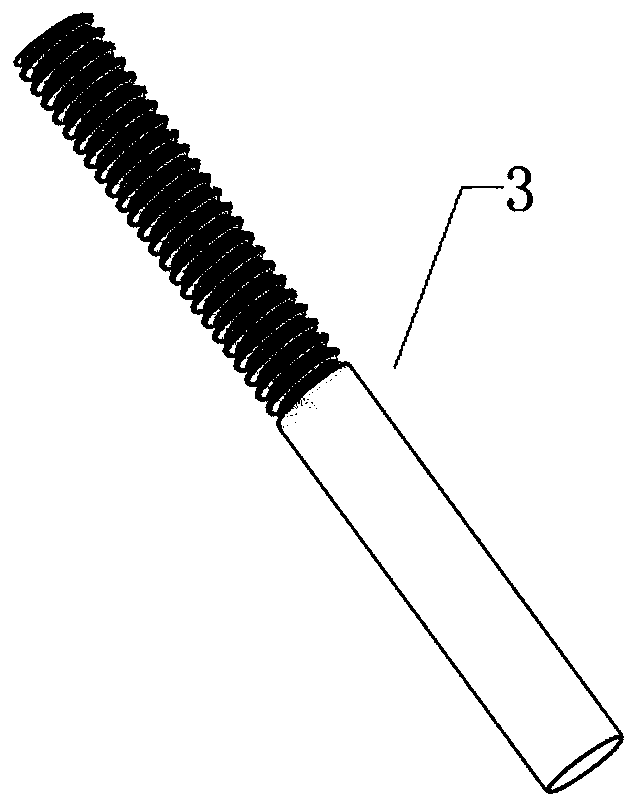

A kind of jig for metallographic analysis samples of thin slices

A metallographic analysis and flake technology, which is applied in the analysis of materials, preparation of test samples, material analysis using wave/particle radiation, etc., can solve the problems of waste of resources, increased cost, time-consuming and laborious, etc. Consistent, simple and reasonable structure, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] When conducting metallographic analysis on the rolled low carbon steel, the end of the steel should be ground and polished. The size of the rolled sample is 10×4×0.5mm, which is difficult to process by hand. If the mosaic method is used, the mosaic material needs to be removed when the sample is scanned and observed with an electron microscope (SEM) after polishing, which is easy to damage the metallography, wastes resources, and increases the cost of the experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com