A bending table for flexible bending center of sheet metal

A sheet material and flexible technology, applied in the field of bending tables, can solve the problems of reducing processing efficiency, unfavorable plate automation, increasing difficulty, etc., and achieves the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below through specific implementation manners in conjunction with the accompanying drawings.

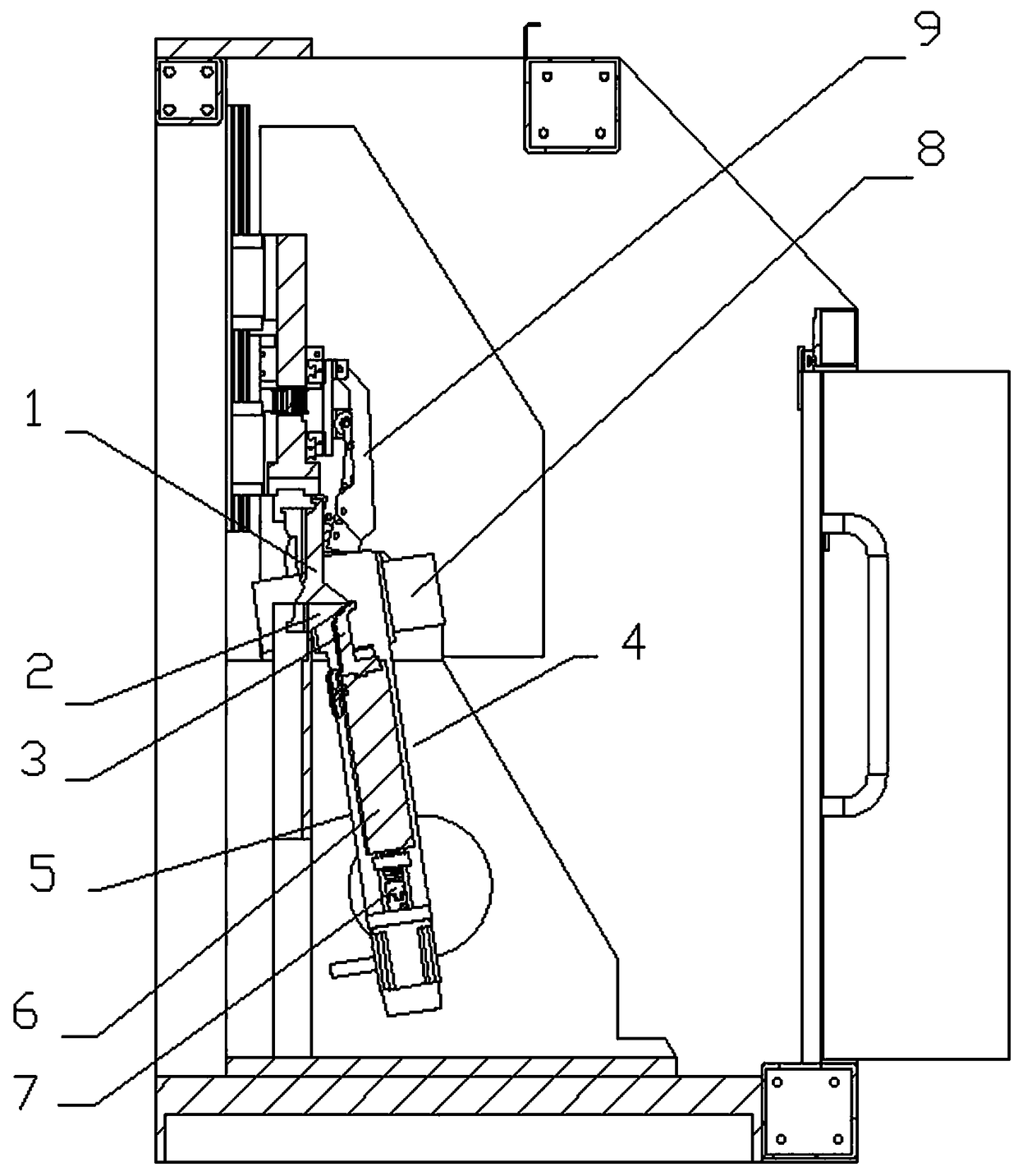

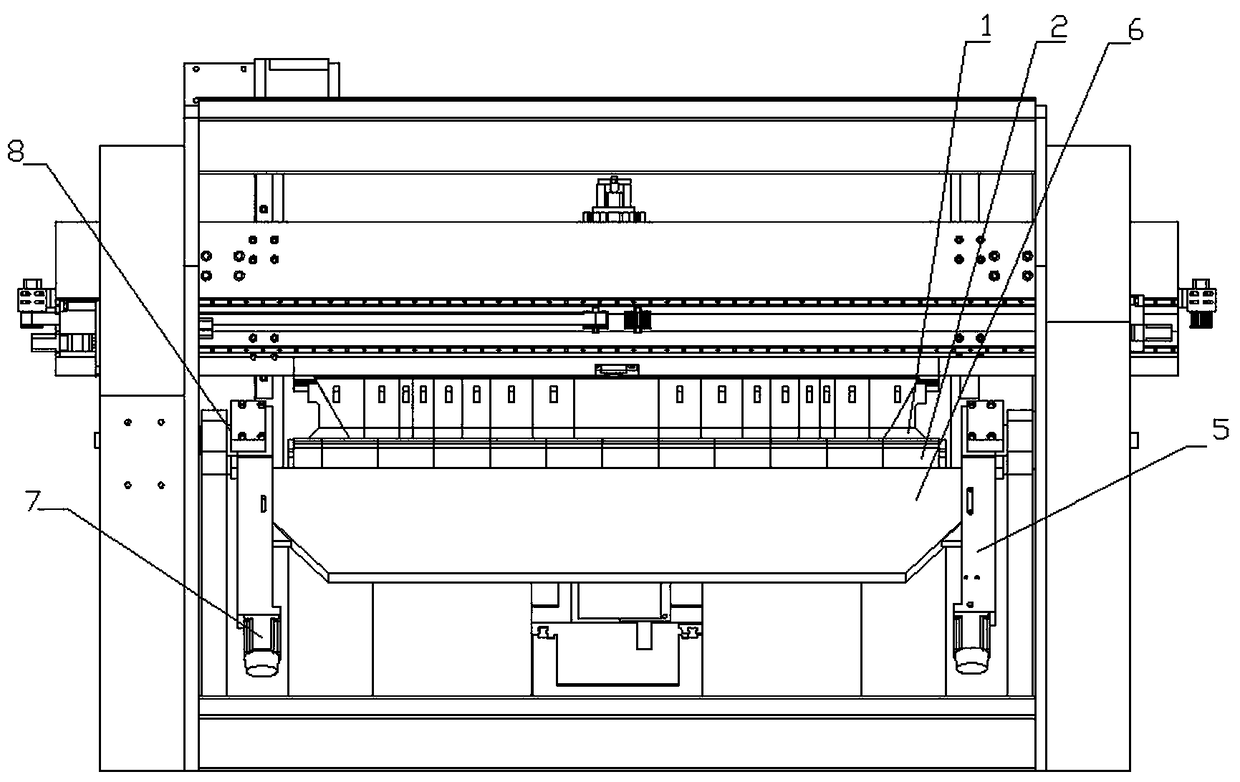

[0018] As shown in the figure, a bending table used for the flexible bending center of plates is set on one side of the rotating table of the flexible bending center of plates. The front of the bending table faces the rotating table, and the bending table is equipped with clamping The upper pressing knife 1 and the lower pressing knife 2 of the plate and the turning knife 4 for bending the plate, the lower pressing knife 2 is fixedly arranged on the positioning platform of the bending table, and the knife surface of the lower pressing knife 2 is in contact with the table surface of the rotary table Flat, the upper press knife 1 is installed above the lower press knife 2 through the lifting mechanism provided on the top of the bending table to compress or loosen the plate on the lower press knife 2. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com