Metallurgy valve welding tool

A welding tool and valve technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve problems such as lack of positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

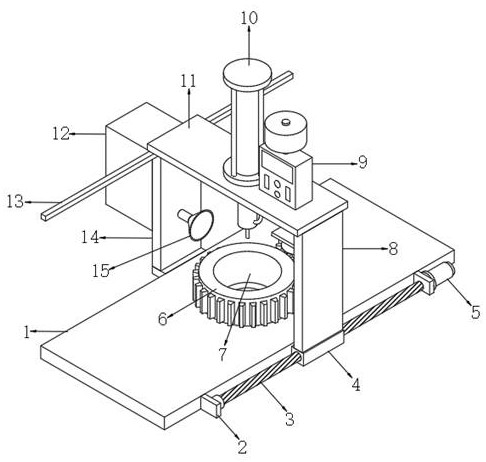

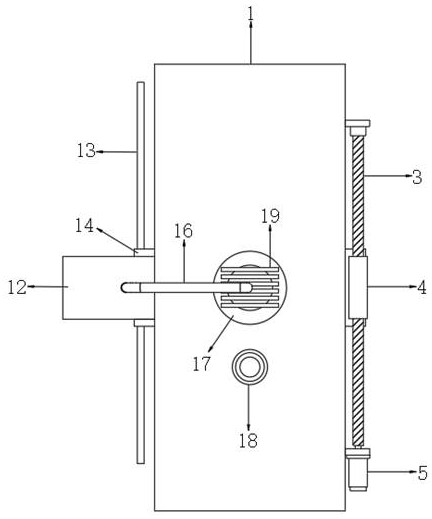

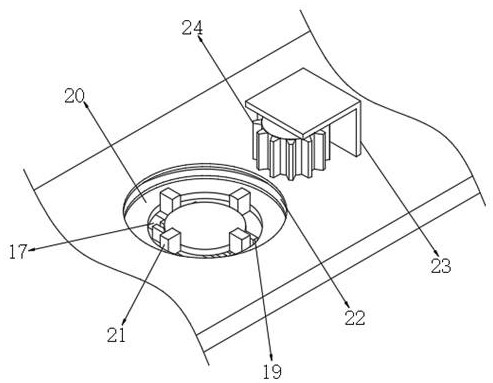

[0033] Metallurgical valve welding plant, such as Figure 1-6As shown, including a table 1, one side wall of the table 1 is connected to the forward mechanism through the bolt, and the top portion of the forward mechanism is connected to the support plate 8 through the bolt, and the top welding of the top plate 11 of the support plate 8, the top plate 11 The side is connected to the welding mechanism through the bolt, and the upper intermediate position of the table 1 is opened, and the positioning seat 6 is inserted inside the mounting groove 20, and the top intermediate position of the positioning seat 6 opens a positioning groove 7, the positioning groove 7 The intermediate position of the bottom inner wall is connected to the suction barrier 27 by bolts, and both sides of the positioning groove 7 have a vertical groove 25, and the vertical groove 25 is rotated between the opposite side inner walls of the top by a pin shaft. 29 The bottom side of the movable frame 29 is welded w...

Embodiment 2

[0043] Metallurgical valve welding plant, such as Figure 7 As shown, in order to solve the problem of adsorption of metal scraps of the welding process being suction block 27; the present embodiment, the following improvements are made based on the first embodiment: replace the first heat sink 19 and the second heat sink 37. The heat absorbing plate 41 is opened on both sides of the top of the positioning seat 6, and the heat absorbing plate 41 is engaged inside the groove.

[0044] When the embodiment is used, the user replaces the first heat sink 19 and the second heat sink 37 by the heat absorbing plate 41. When the gas is discharged into the welding through the exhaust pipe 16, the welding process can be absorbed by the heat absorbing plate 41. The heat generated by the arc, the heat of the welding, and the heat in the gas such that the top of the positioning seat 6 produces a certain high temperature, using high temperature eliminating the magnetic force to the top of the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com