Calculation Method of 3D Contact Stiffness of Spur Gear Based on Rough Surface

A technology of contact stiffness and rough surface, which is applied in the field of calculation of three-dimensional contact stiffness of spur gears, can solve problems such as the inability to accurately simulate the deformation of the rough surface contact state of gear teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

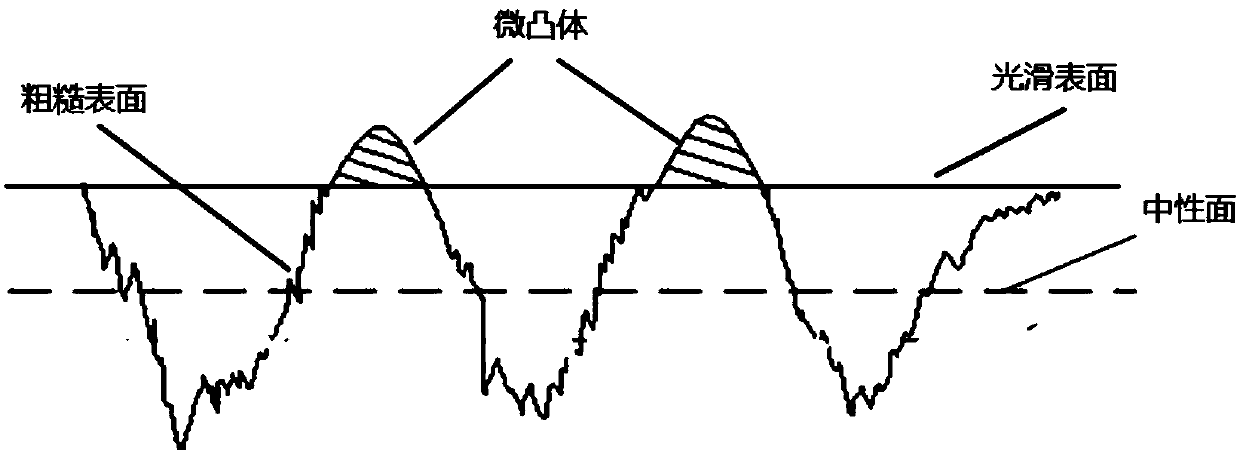

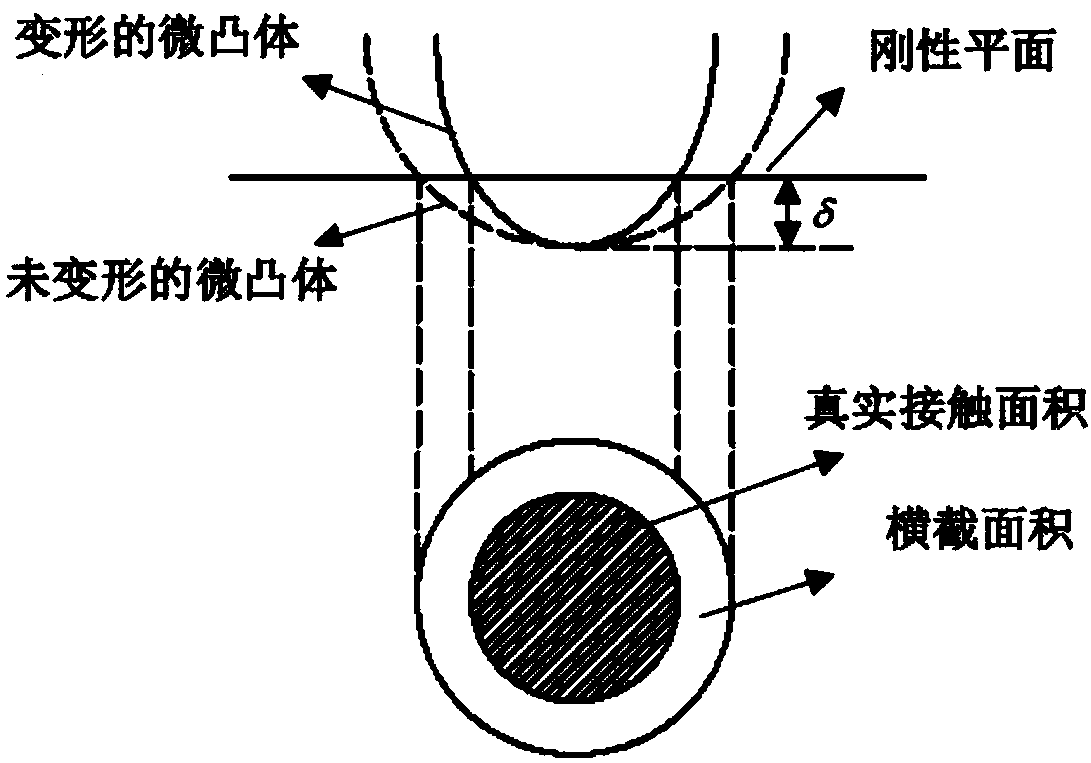

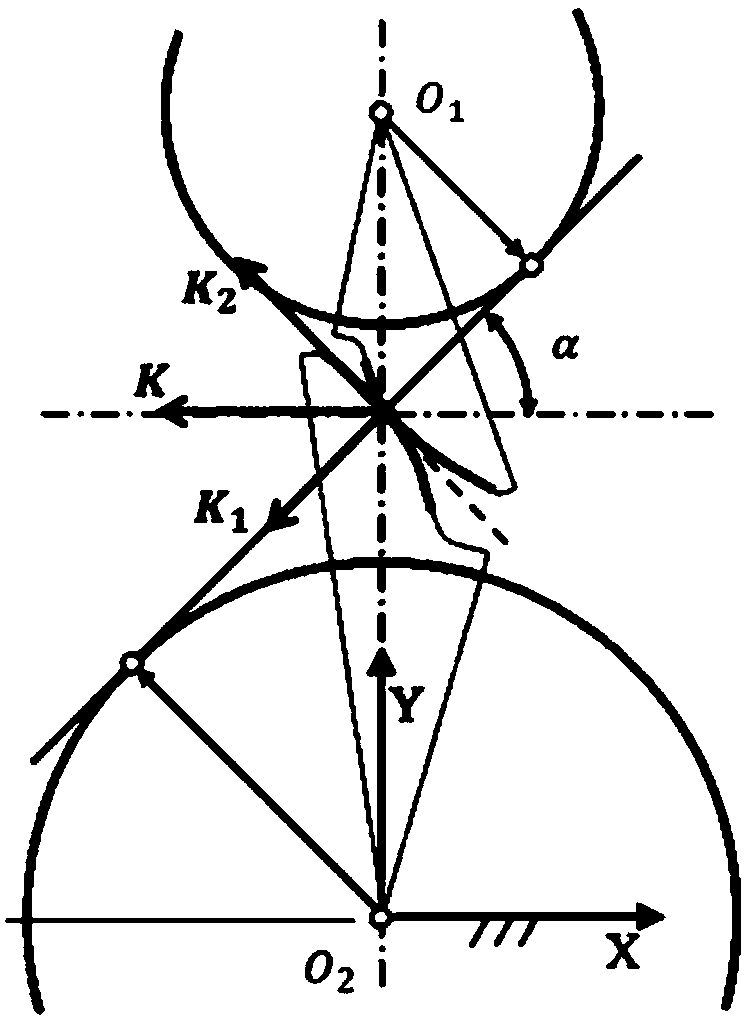

[0071] Attached below Figure 1-3 And embodiment further illustrate the present invention.

[0072] A method for calculating the three-dimensional contact stiffness of spur gears based on a rough surface, comprising the following steps:

[0073] 1) For the specific grid division of the gear pair, the area of each grid is required to be A 0 equal;

[0074] 2) Calculate the contact pressure distribution on the smooth tooth surface based on the finite element method, and extract the node pressure P in the contact area i ;

[0075] 3) Calculate the normal contact stiffness K of a single square grid based on fractal theory N , the tangential contact stiffness K T ;

[0076] 4) Calculate the contact stiffness K of the tooth surface.

[0077] Described step 1) specifically comprises the following steps:

[0078] The gear pair is divided into hexahedral grids, and the side length of the hexahedral grid is constrained to be 2mm. Therefore, it can be obtained that the contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com