Centrifugal oil-purifying system with protection device

A protective device and centrifugal technology, applied in the direction of filtration separation, separation method, liquid separation, etc., can solve the problems of damage, low equipment, etc., and achieve the effect of controlling economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

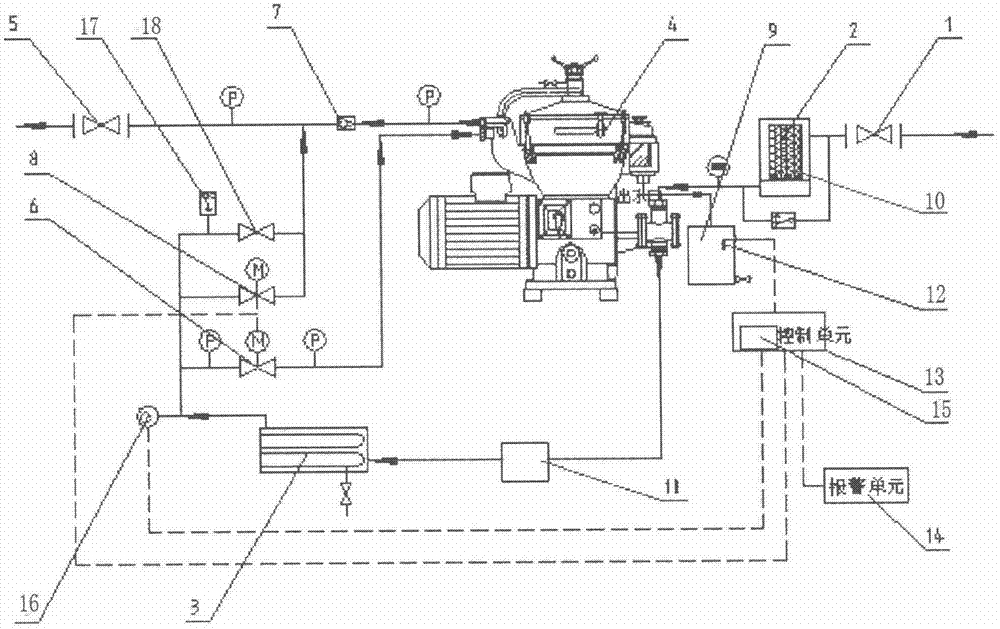

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] Such as figure 1 As shown in the figure, a centrifugal oil purification system with a protection device includes an oil inlet valve 1, an inlet filter 2, a heater 3, a centrifugal separator 4, and an oil outlet valve 5 connected in series in the main oil circuit. An oil inlet electromagnetic valve 6 is arranged between the electric heater 3 and the centrifugal separator 4, and a check valve 7 is arranged at the oil outlet of the centrifugal separator 4, and the oil inlet of the oil inlet electromagnetic valve 6 A bypass solenoid valve 8 is provided between the port and the oil outlet of the one-way valve 7, and a liquid level sensor 10 is provided in the inlet filter 2; The sensor 11; the water outlet of the centrifugal separator 4 is connected with the water collection tank 9, and the water collection tank 9 is provided with a liquid level controller 12; the contro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap