Mechanical seal limiting mechanism

A technology of limit mechanism and mechanical seal, applied in the direction of engine seal, mechanical equipment, engine components, etc., can solve the problems affecting the limit of mechanical seal, cumbersome installation and disassembly, screw breakage, etc., to achieve good stability, maintenance and stability. The effect of convenient replacement of parts and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

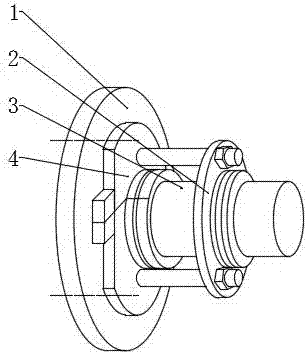

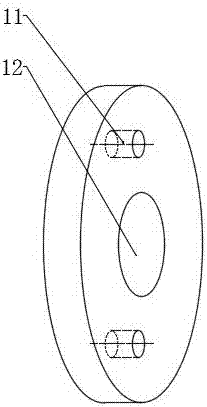

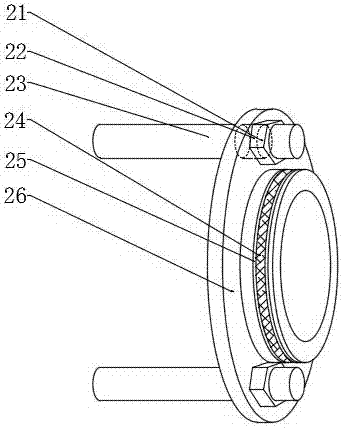

[0027] The specific embodiment: when the operator installs the limit block 4, first the upper half ring 43 and the lower half ring 46 of the limit block 4 rotate around the rotating shaft connecting the two, and the limit block 4 is installed on the concave hole on the shaft 3. In the groove, then rotate the limiting block 4 around the shaft 3 until the positioning block 42 is installed in the positioning hole 11, and realize the preliminary positioning of the limiting block 4 and the static ring end cover 1, and then screw the front of the upper half ring 43 The lower end of the bottom part is connected with the front upper end of the lower half ring, and finally the O-ring 2 44 is installed on the sealing ring groove 2 45. This design enables a better positioning between the limit block 4 and the static ring end cover 1 The connection solves the problem that the screw is broken due to 3 rotations of the shaft, thereby affecting the stability of the limit mechanism. In additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com