Improved type fire extinguisher storage box fixing frame

A fire extinguisher and storage box technology, which is applied in fire rescue and other fields, can solve problems such as difficult alignment, difficult fixing methods, and difficulty in forming expectations, so as to achieve the effect of avoiding misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

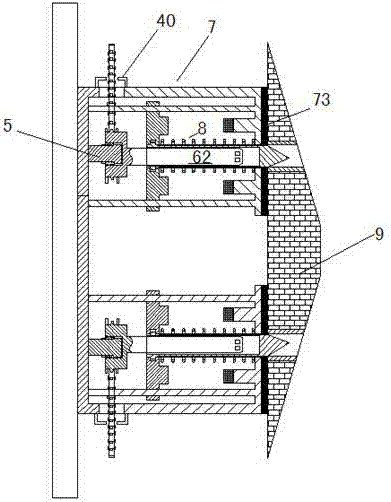

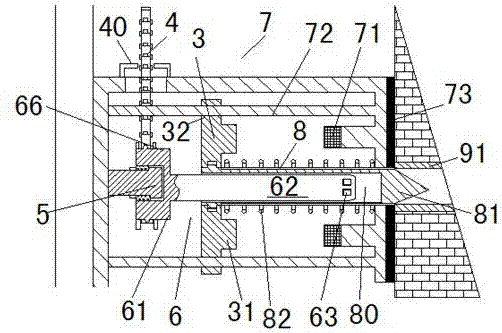

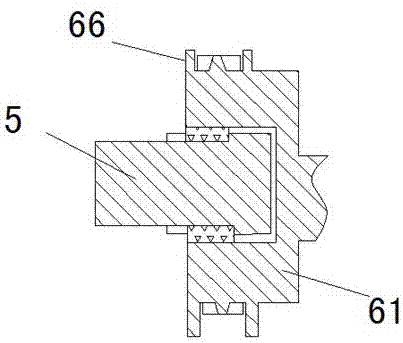

[0010] Combine below Figure 1-3 The present invention will be described in detail.

[0011] combine Figure 1-3 , an improved fire extinguisher storage box fixing frame according to an embodiment of the present invention, comprising a frame 7 and shell screw-fastening assemblies respectively located at the upper end and the lower end of the frame 7, each of the shells The inner tightening assembly includes a threaded tongue piece 8 for threading into a threaded pipe sleeve 91 fixed in the wall 9, a push sliding part 3 connected with the threaded tongue piece 8 through a bearing, and a The drive slide bar 62 that slides into the inner chute 80 of the threaded tongue member 8, and the turntable that is fixedly connected with the frame 7 and is rotatably supported on the drive slide bar 62 The suspending shaft 5 of the sleeve 61; wherein, the push slide part 3 is provided with a push convex part 31 on the periphery of the threaded tongue part 8 for contacting the compression r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com