Unilateral opposite-pull screw system

A technology for pulling screws and systems, which is used in the connection of formwork/formwork/work frame, the on-site preparation of building components, and construction, etc., which can solve the problems of frequent upper and lower stools by operators and frequent movement of moulding stools. , to achieve the effect of reducing personnel collaborative work, saving fastening installation work, and improving installation work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to facilitate the understanding of the present invention, the following will describe the present invention more fully. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. On the contrary, these embodiments are provided to make the understanding of the disclosure of the present invention more thorough and comprehensive.

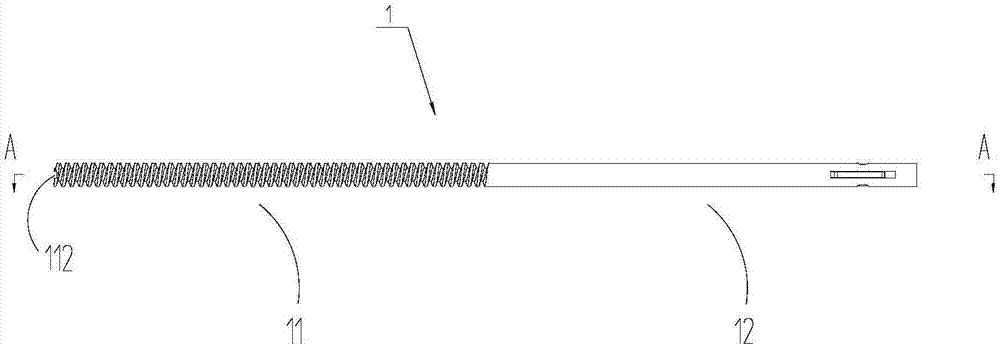

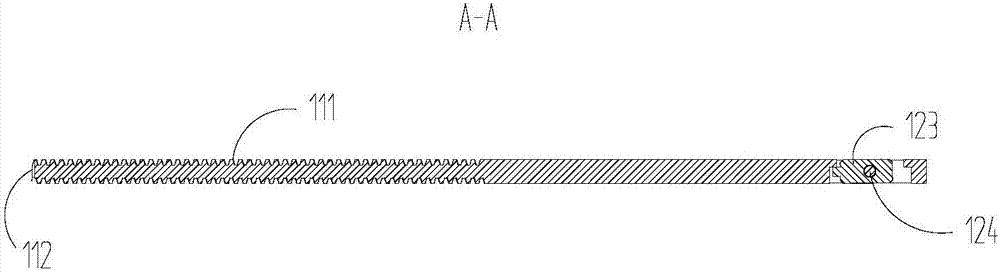

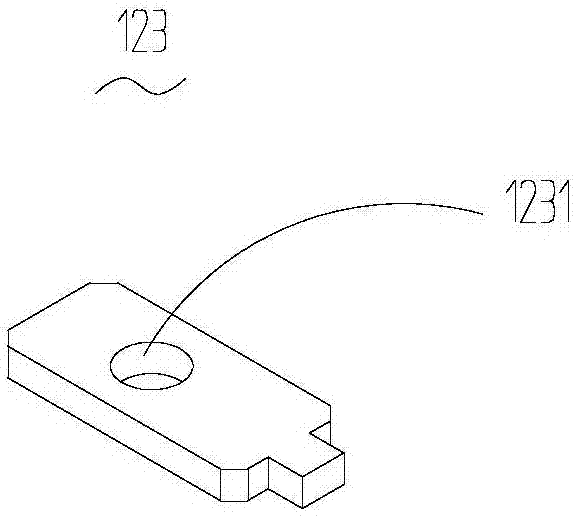

[0046] refer to Figure 1-Figure 3 with Figure 5-Figure 8 shown.

[0047] A unilateral tension screw 1 system, comprising: a unilateral tension screw 1, the unilateral tension screw 1 is composed of a threaded section 11 and a non-threaded section 12; the outer cylindrical surface of the threaded section 11 is provided with a connecting thread 111; The end face of the threaded section 11 away from the non-threaded section 12 is provided with a square groove 112; one end of the non-threaded section 12 is provided with a square step groove 121 running through it; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com