IXPE sheet splicing device

A technology of sheets and sliders, which is applied to household appliances, other household appliances, flat products, etc., can solve problems such as inability to splice, worker fatigue, and difficulty in splicing quality, so as to improve splicing efficiency and ensure splicing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

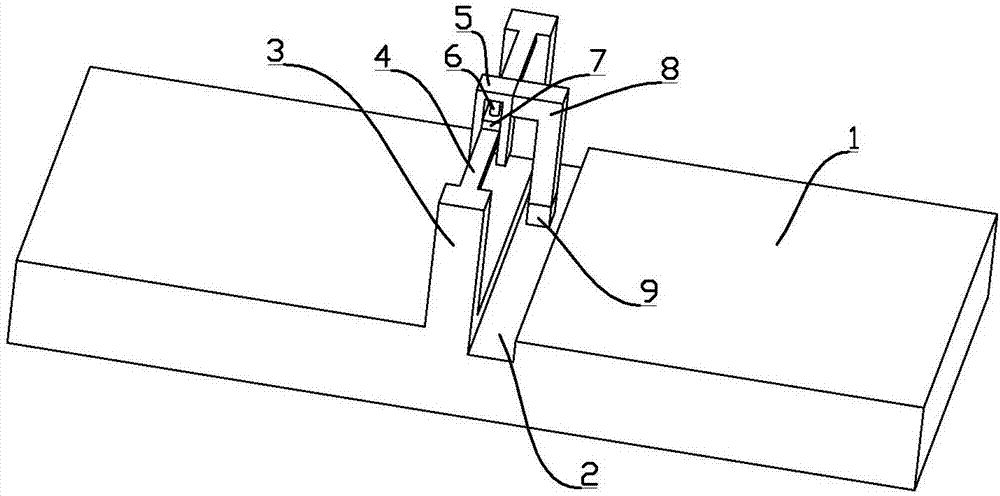

[0012] Such as figure 1 As shown, a splicing device of an IXPE sheet is characterized in that it includes a steel plate 1 provided with a groove 2, and brackets 3 fixed on both sides of the steel plate 1, the top of the bracket 3 is fixed with a 2. Parallel slide bar 4. The slide bar 4 is provided with an inverted U-shaped slide block 5. A spring 6 is arranged in the described U-shaped slide block 5. One end of the spring 6 is connected to the U-shaped slide block 5. The bottom of the inner side of the U-shaped slider 5 is fixed, and the other end is fixed with a sliding piece 7. The outer side of the U-shaped slider 5 is fixedly connected with a nail gun 9 through a connecting rod 8. The nail gun 9 is located directly above the groove 2, so The width of the slide bar 4 is smaller than the width of the top of the support 3, and the support 3 is a telescopic structure with adjustable length.

[0013] When the present invention is in use, the slider 7 of the U-shaped slider 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com