Vacuumizing device used in vacuum pipeline and vacuumizing method of vacuumizing device

A technology of vacuum pumping device and vacuum pipeline, which is applied in transportation and packaging, electric vehicles, sliding/floating railway systems, etc., can solve the problems of low vacuum pumping efficiency, complicated design of vacuum pumping equipment, high construction cost, and maintain air pressure balance. , The effect of convenient and efficient vacuuming operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

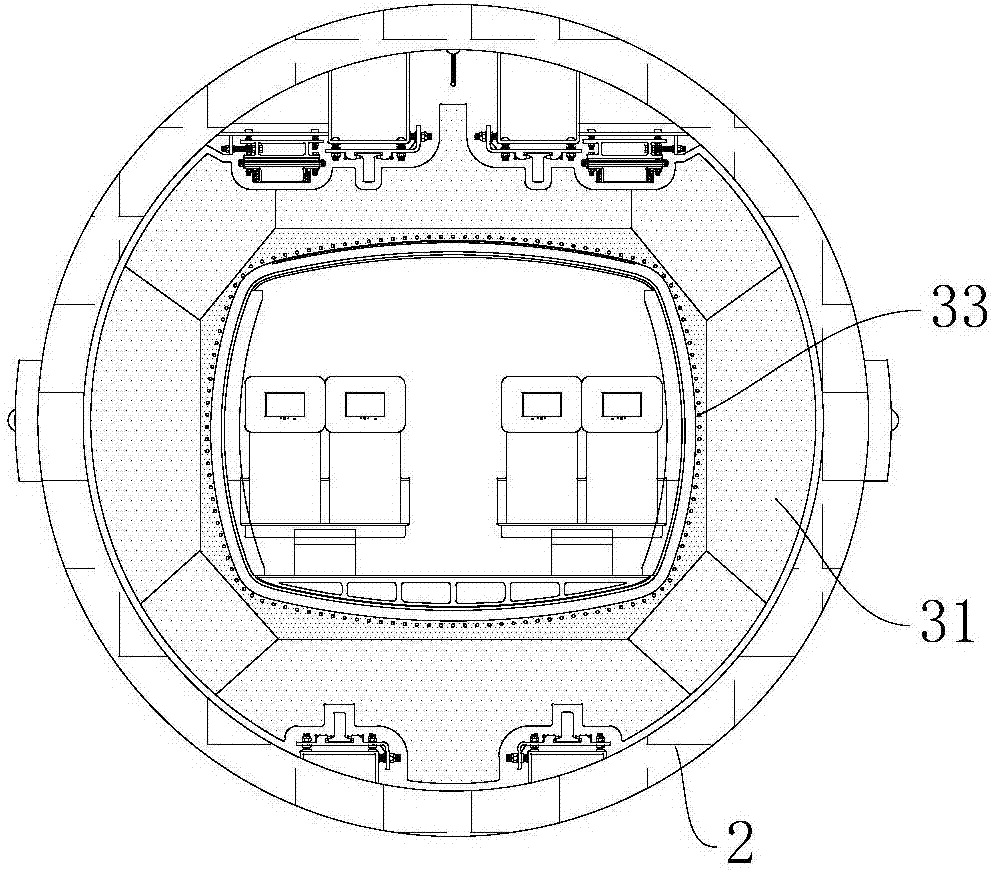

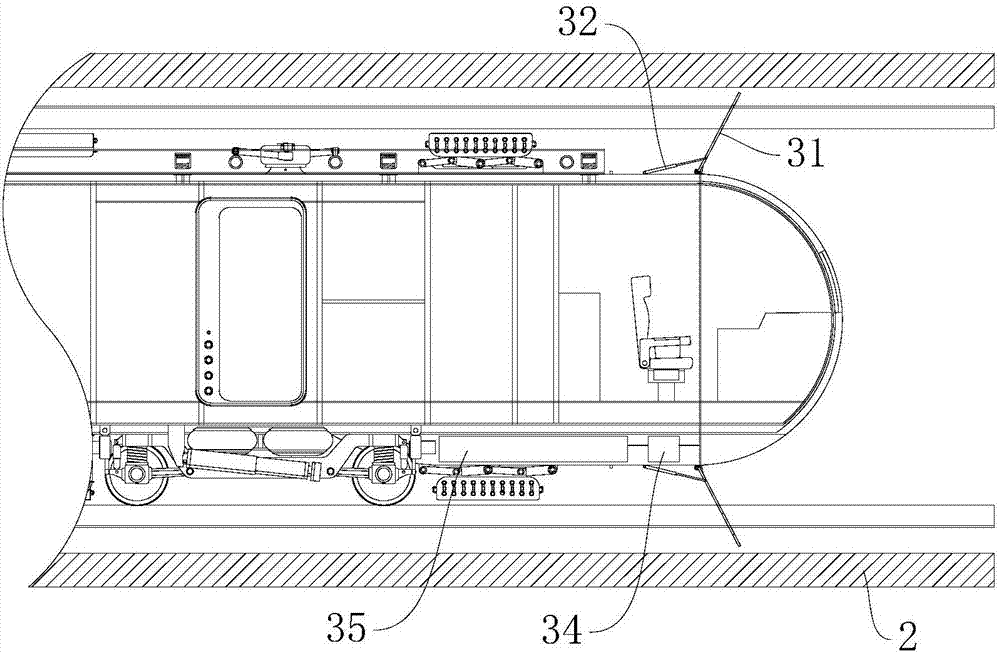

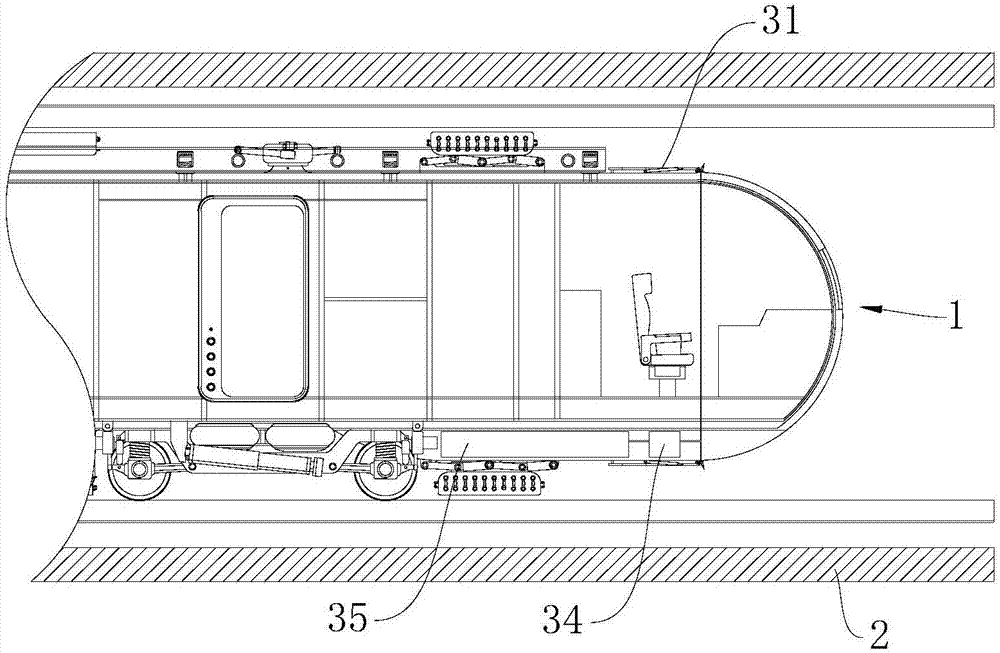

[0024] combine Figure 1 to Figure 3 As shown, the present embodiment provides a vacuum pumping device for a vacuum pipeline, including an external vacuum pumping device arranged outside the vacuum pipe, and an internal vacuum pumping device arranged inside the vacuum pipe 2; the internal vacuum pumping device It includes a windshield 31 arranged at the head of the high-speed train 1 to cooperate with the inner wall of the vacuum pipe 2 of the high-speed train 1 after being deployed, and a windshield 31 connected with the windshield 31 for driving the opening and closing of the windshield 31 The driving mechanism 32 and the gas collection device provided through the air collection channel 33 of the windshield 31 , the gas collection device is fastened to the high-speed train 1 .

[0025] Specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com