Testing device and test method for peeling torque of synchronization ring

A technology for torque testing and synchronizing rings, applied in the field of synchronizing ring peeling torque testing devices, can solve the problems of large synchronizing ring peeling torque, inability to accurately measure the synchronizing ring peeling torque, inability to calculate the synchronizing ring peeling torque, etc. stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

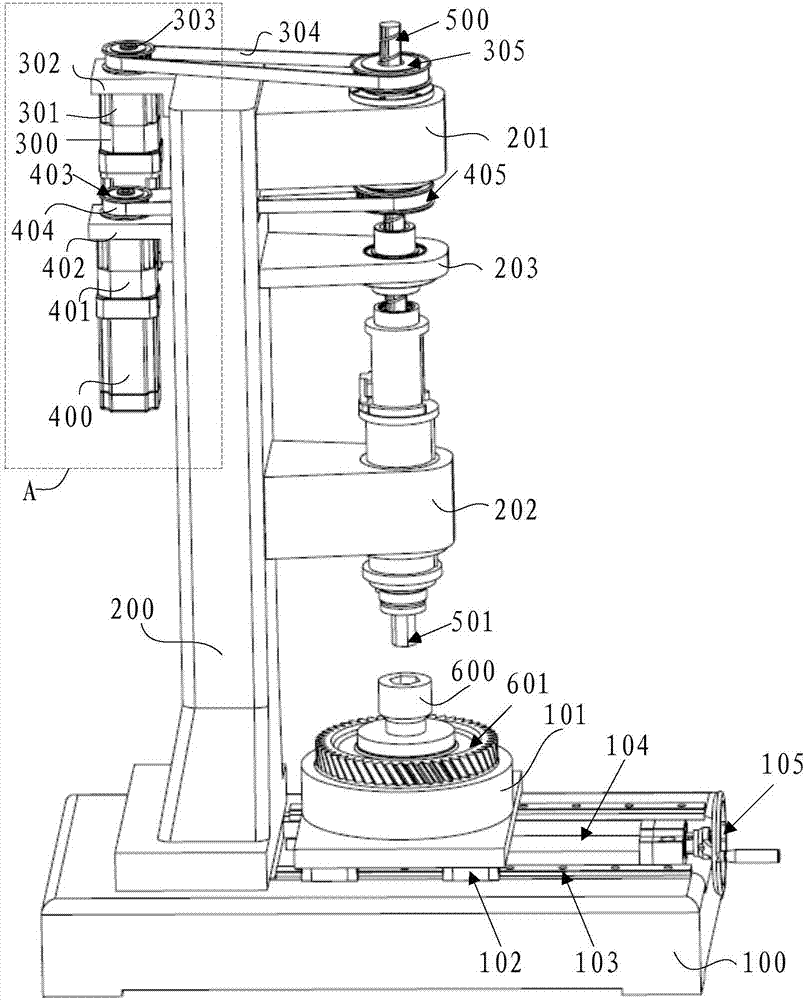

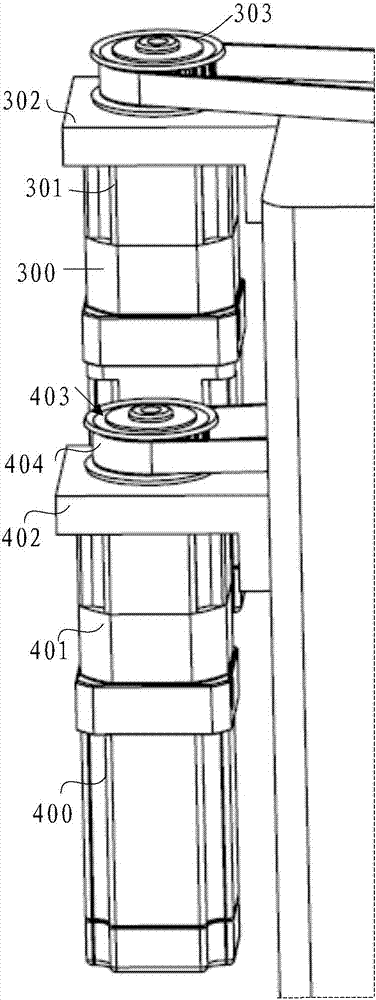

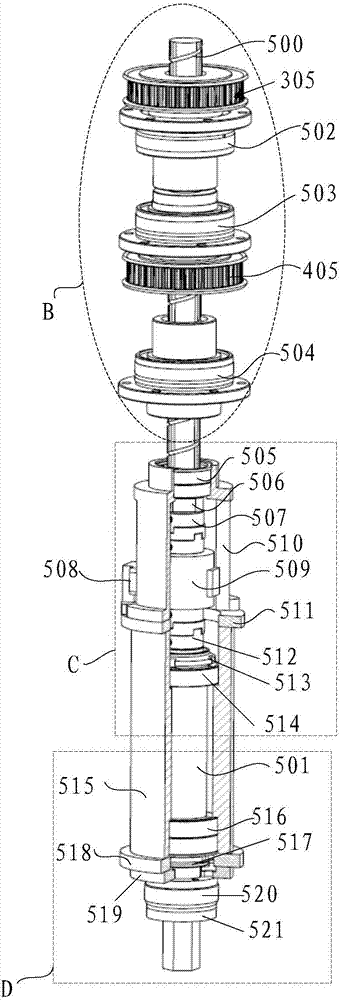

[0033] refer to figure 1 , the embodiment of the present invention provides a synchronous ring peeling torque testing device for testing the synchronous ring peeling torque, comprising: a test bench, a support portion arranged on the test bench; a rotating shaft 501 arranged on the supporting portion, the rotating shaft 501 Can rotate around its own axis and can move on the support part along its own axis direction; the rotating shaft 501 has a first end and a second end, the first end faces the test platform, and the second end faces away from the test platform; the rotating shaft 501 is fixedly connected Torque sensor 509 is used to test the torque of rotating shaft 501; the mounting groove on the test bench is used to install the synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com