Braking modified structure

A technology of improved structure and brake block, which is applied to bicycle accessories, bicycle brakes, etc., can solve the problems of increasing the braking force, changing the braking effect, and not being able to automatically increase the brake clamping force, so as to increase the brake clamping force and lift the brake. effect of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

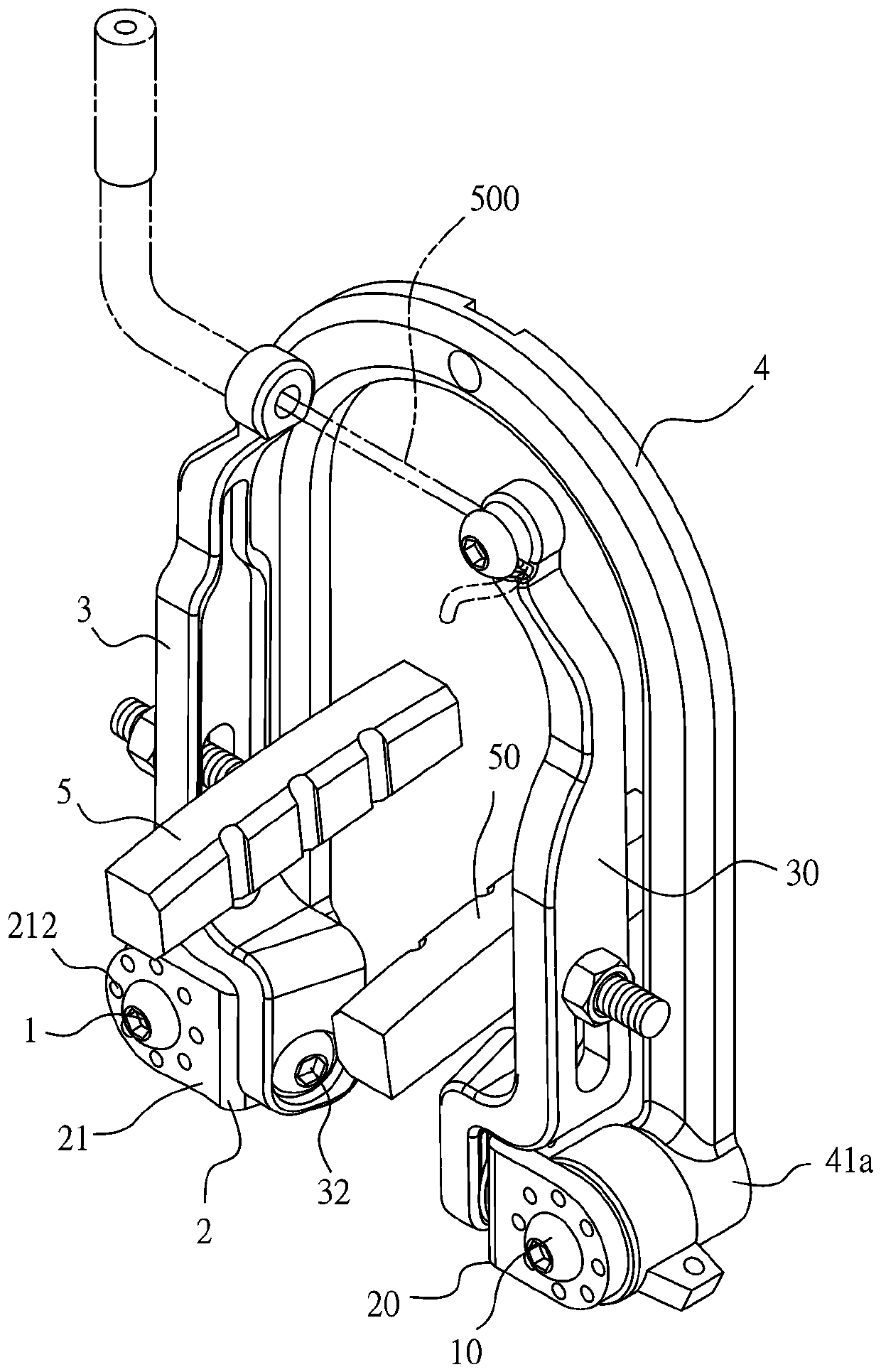

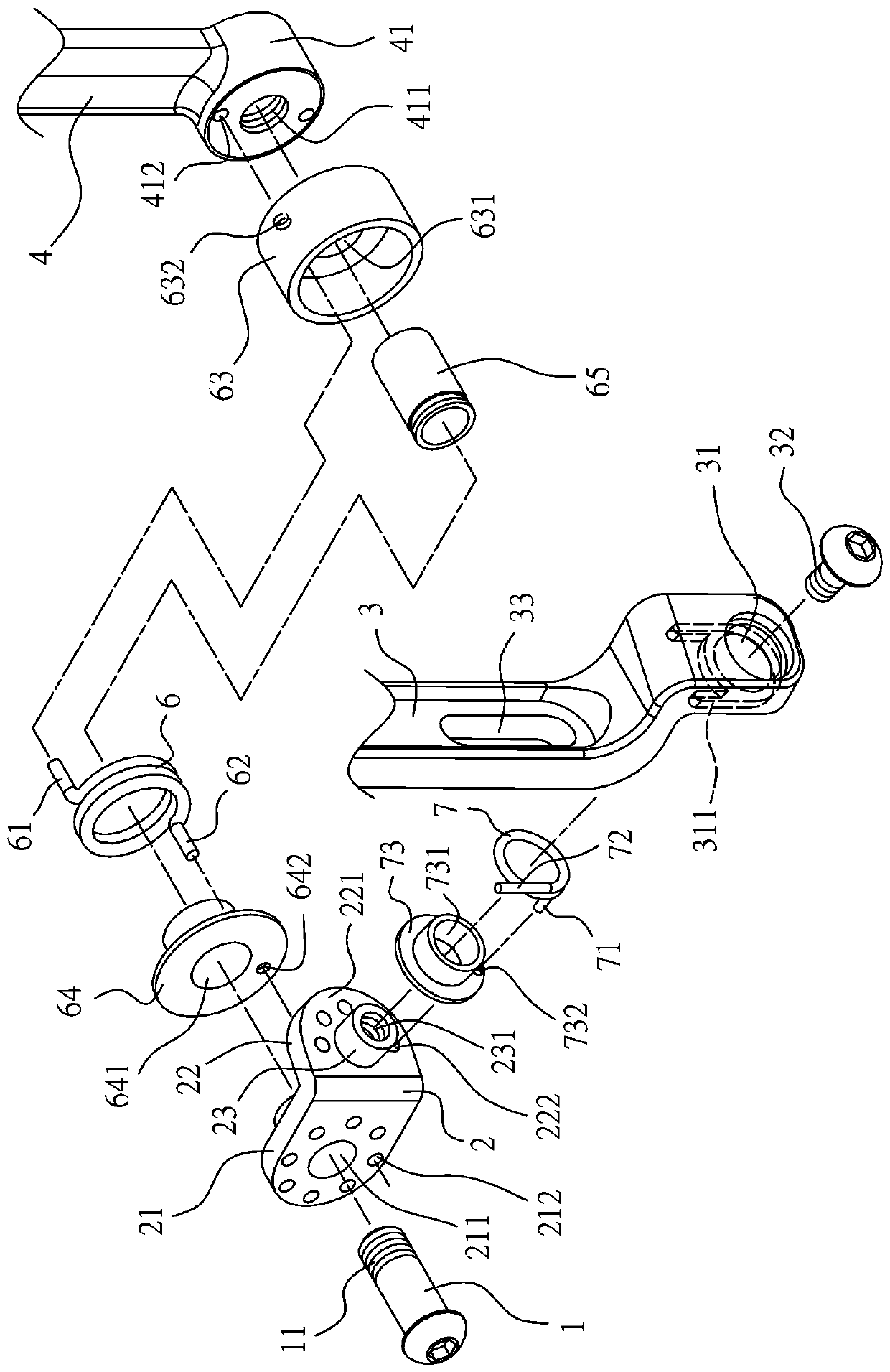

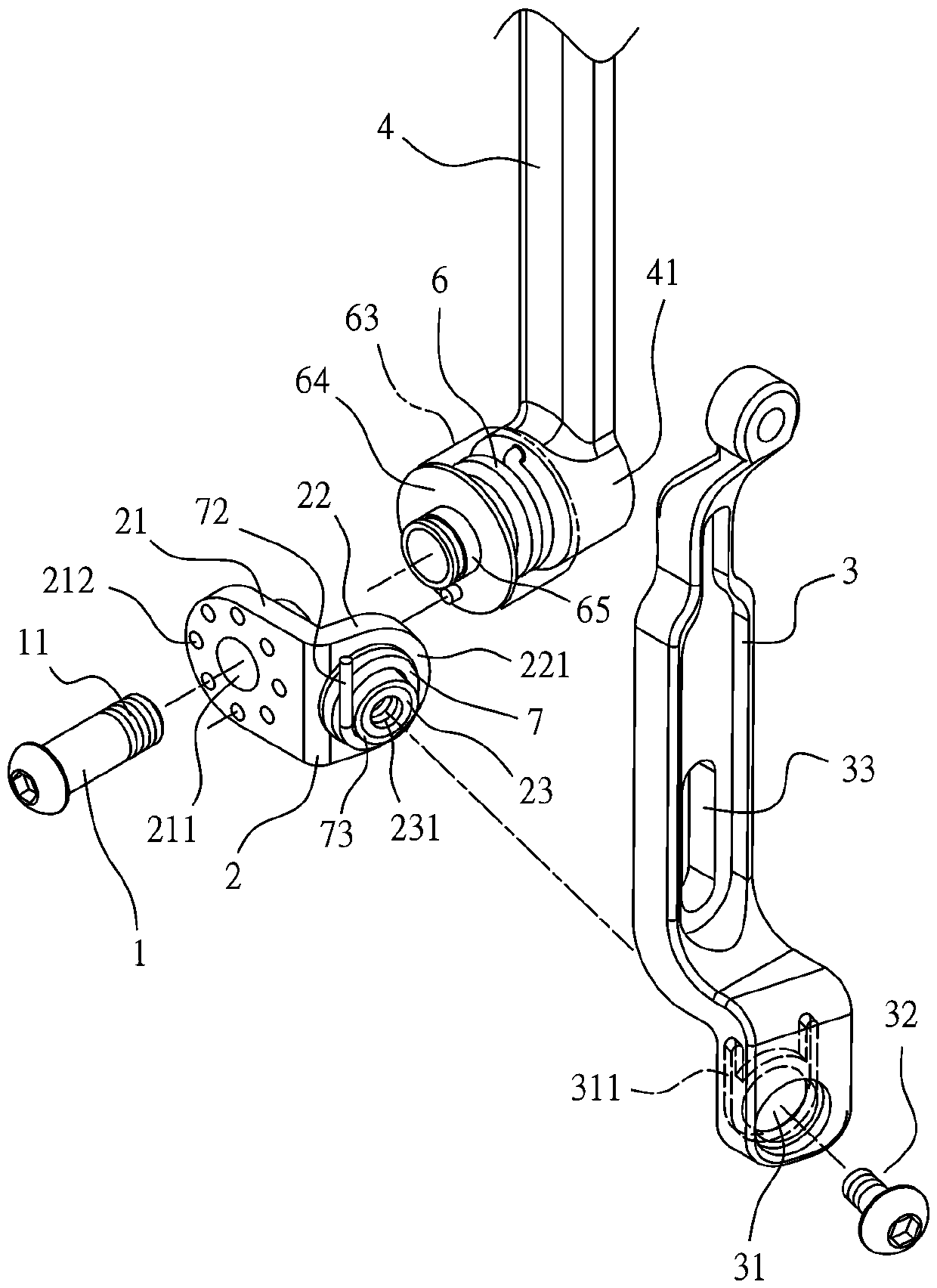

[0083] See Figure 1 to Figure 5 As shown, it can be seen that the first embodiment of the present invention takes the form of a bicycle as an example. The main structure includes two main shaft bolts 1, 10, two receiving parts 2, 20, and two clamp arms 3, 30, etc.; wherein the main shaft bolt 1 One end is provided with an external thread 11; in this embodiment, there is another U-shaped bracket 4 fixed on the bicycle frame. The two ends of the bracket 4 extend on both sides of the wheel and are respectively provided with the same seat 41, 41a, a threaded hole 411 perpendicular to the wheel axis is provided on the seat 41, and at least one recessed hole 412 is provided beside the threaded hole 411, and the outer thread 11 of each spindle bolt 1 is screwed into each threaded hole 411, The spindle bolt 1 can be coupled to the seat 41 in a direction perpendicular to the wheel axis.

[0084] The spindle bolt 10 has the same structure as the spindle bolt 1 and can be combined on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com