Folded top hinge block and method for installing same

A hinged block, longitudinal direction technology, applied in cranes and other directions, to achieve the effect of improving the installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

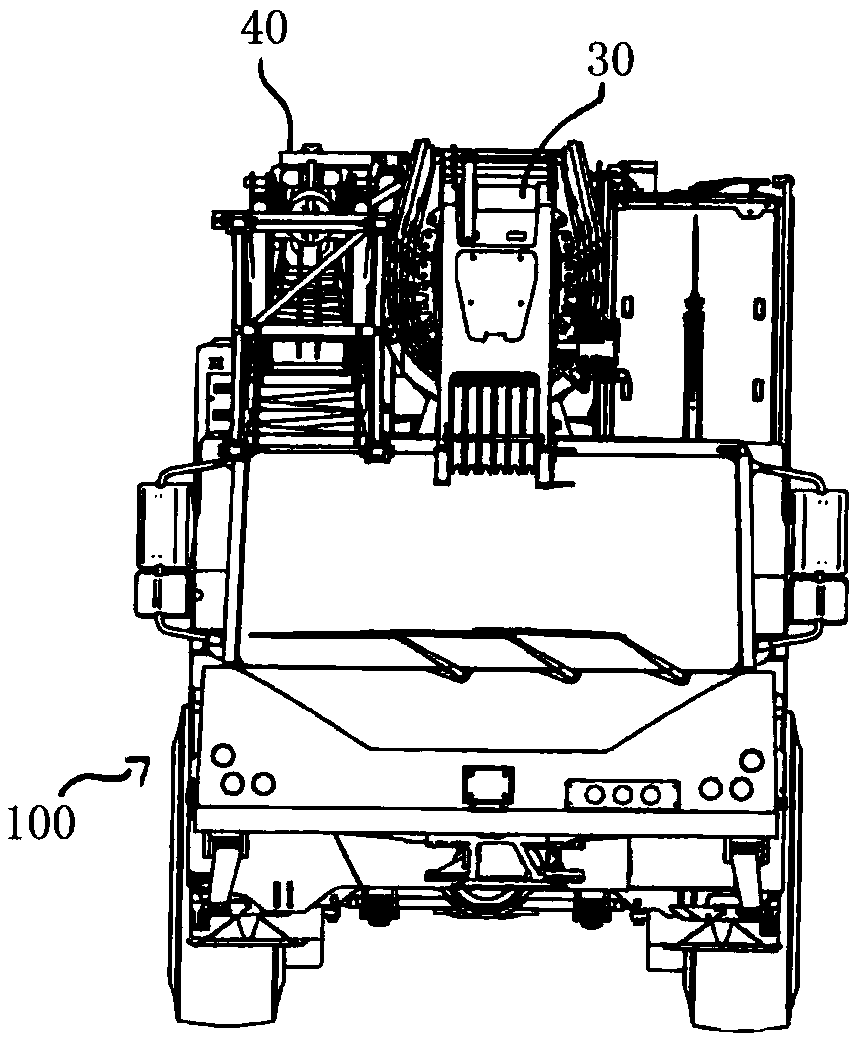

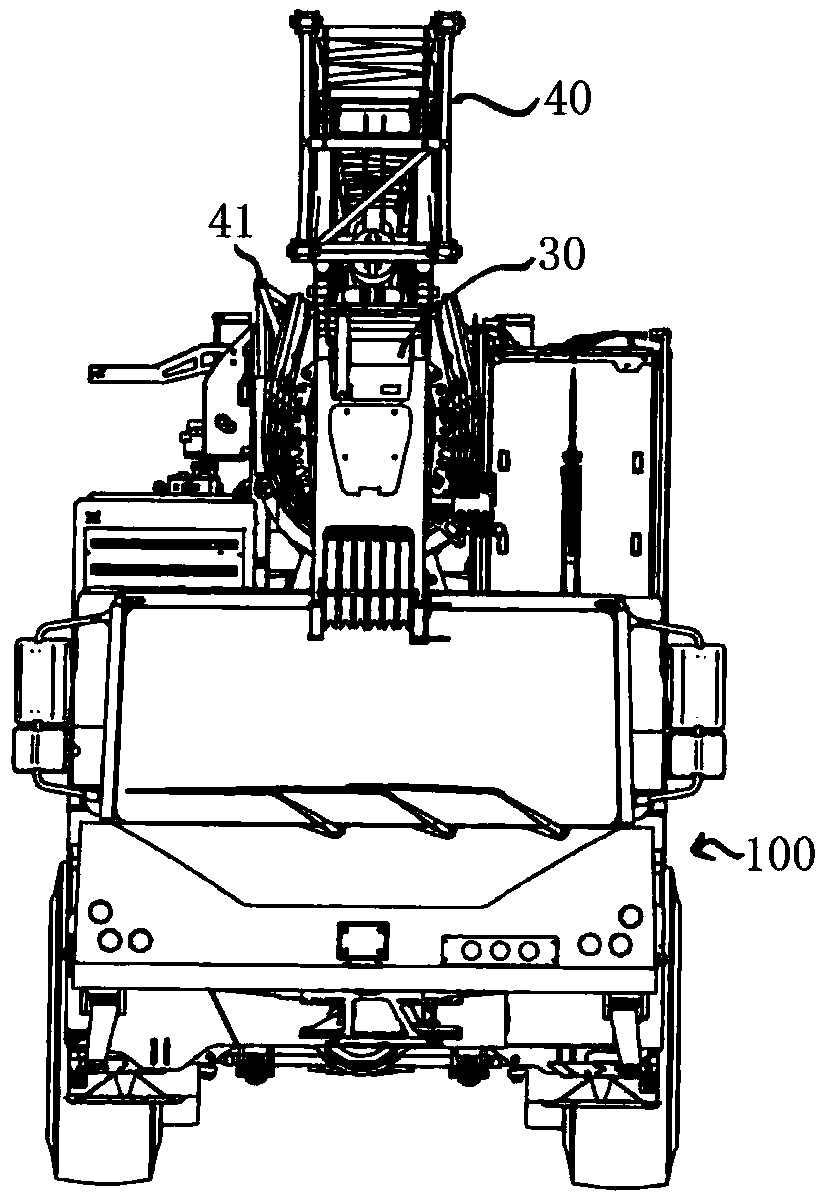

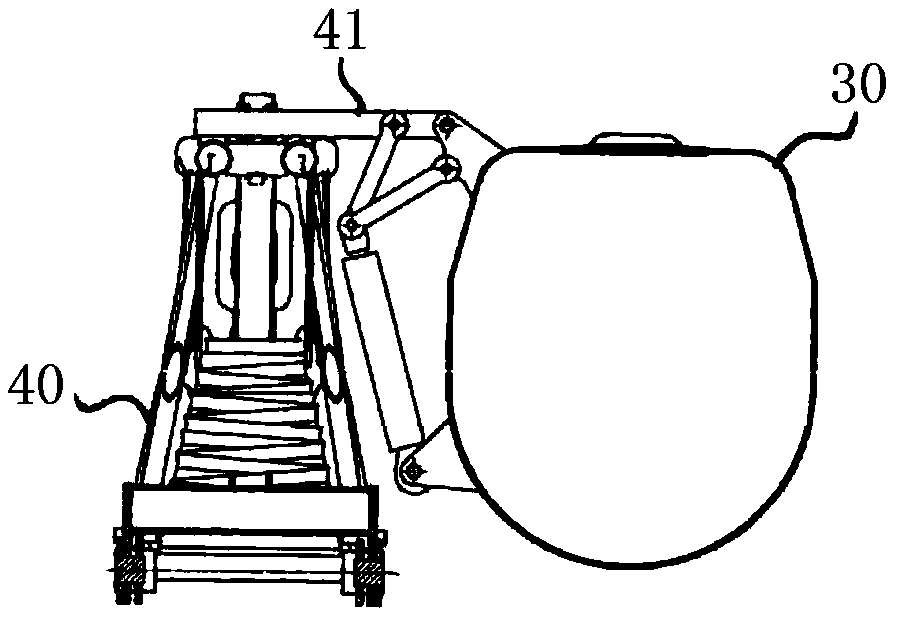

[0044] The principle sequence of the installation of the folding top is explained below by description according to the sequence of the drawings. According to the invention, the folding top is continuously hydraulically guided here, which contributes to reducing the probability of failure. Furthermore, during the transition between the transport position and the working position, the folding top is permanently connected to the main boom by means of a hinged connection (support 41 or pivot axis 33 ).

[0045] exist Figure 1a The folding top 40 can be seen in , which is arranged laterally offset from the main boom 30 of the mobile crane 100 . Here, the folding top 40 is suspended on two supports 41 , which are used to pivot the folding top 40 upwards by 180 degrees and to place the folding top 40 on the main boom 30 . The main boom 30 may in particular be a telescoping main boom. The folding top 40 is also fixed in position on the upper side of the main boom 30 by brackets 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com