High speed train non-power wheel pair axle box device for standard-narrow gauge conversion

A high-speed EMU, non-power technology, applied in axle box installation, transportation and packaging, railway car body parts, etc., can solve the problem that quasi-narrow gauge conversion function cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

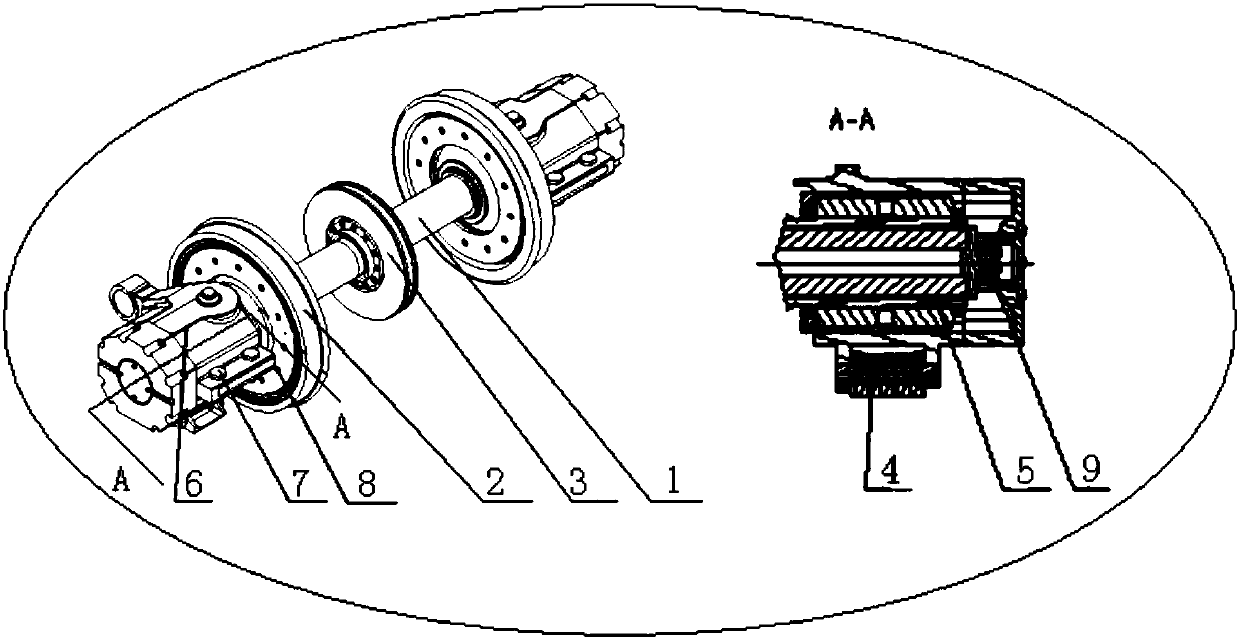

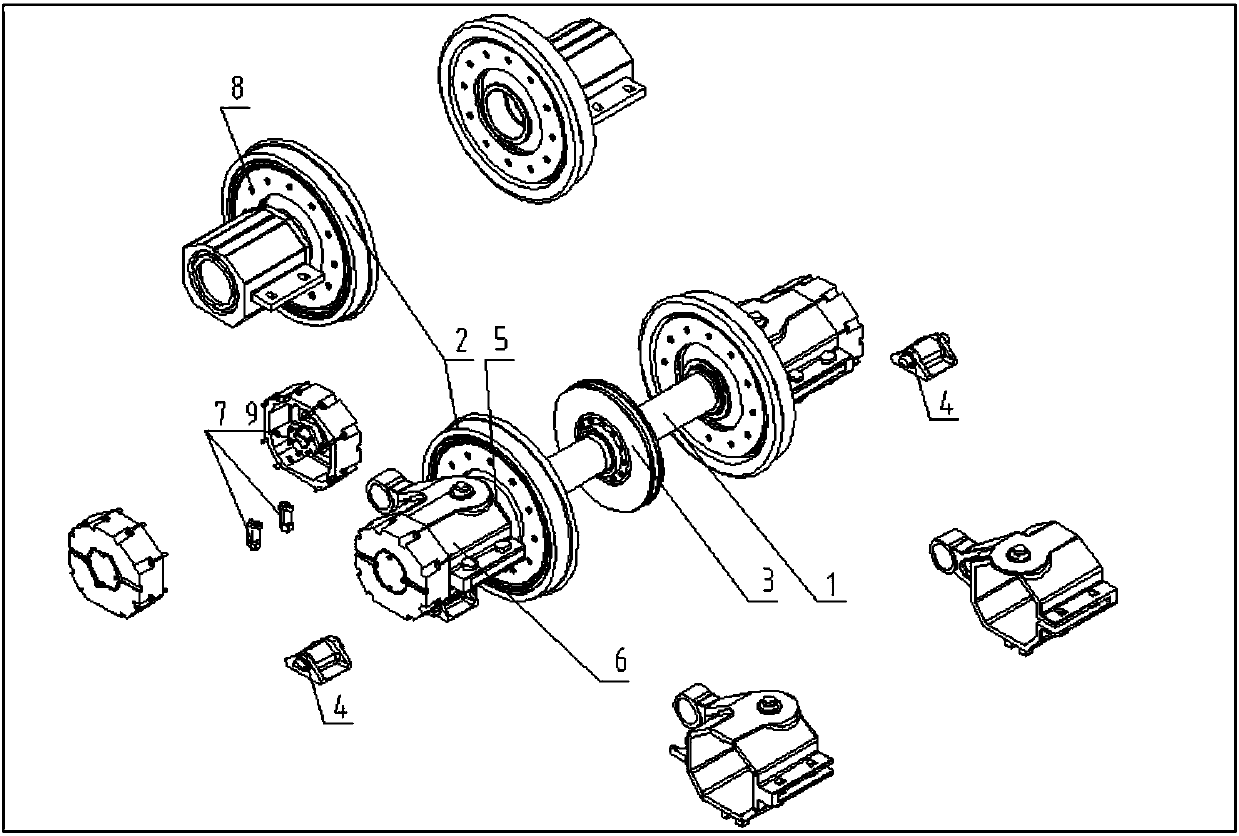

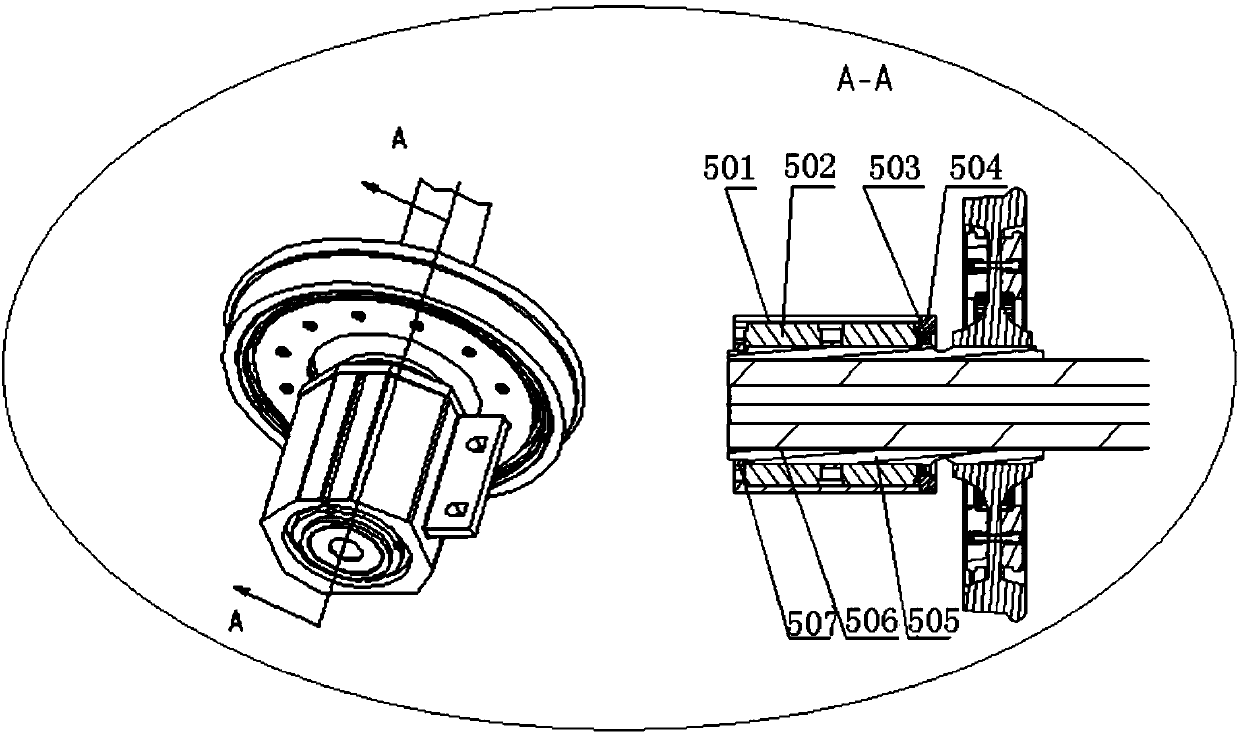

[0020] refer to figure 1 , figure 2 , the specific embodiment of the present invention includes a non-powered axle 1, a wheel 2, an axle-mounted brake disc 3, a bearing seat 4, a sliding mechanism 5, an axle box arm beam 6, a locking positioning pin 7, and a wheel-mounted brake disc 8 , Axial positioning mechanism 9, the wheel-mounted brake disc 8 is connected to the wheel 2 through fasteners, the sliding mechanism 5 is installed on the non-powered axle 1, and is axially fixed by locking the positioning pin 7. The wheels 2 and the pivoting arm beams 6 of the axle box are respectively set and fixed on the sliding mechanism 5. The sliding mechanism 5 is used to drive the wheels 2 to slide on the non-powered axle 1 when changing the track, and cooperate with the non-powered axle to transmit torque during operation. The wheel is driven to rotate, and the locking positioning pin 7 is arranged between the sliding mechanism 5 and the pivoting arm beam 6 of the axle box. Sliding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com