High-speed EMU power wheel pair axle box device for conversion between standard gauge and wide gauge

A high-speed EMU and power wheel technology, applied in the direction of axle box installation, etc., can solve the problems of low operation efficiency, increased labor and material costs, and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

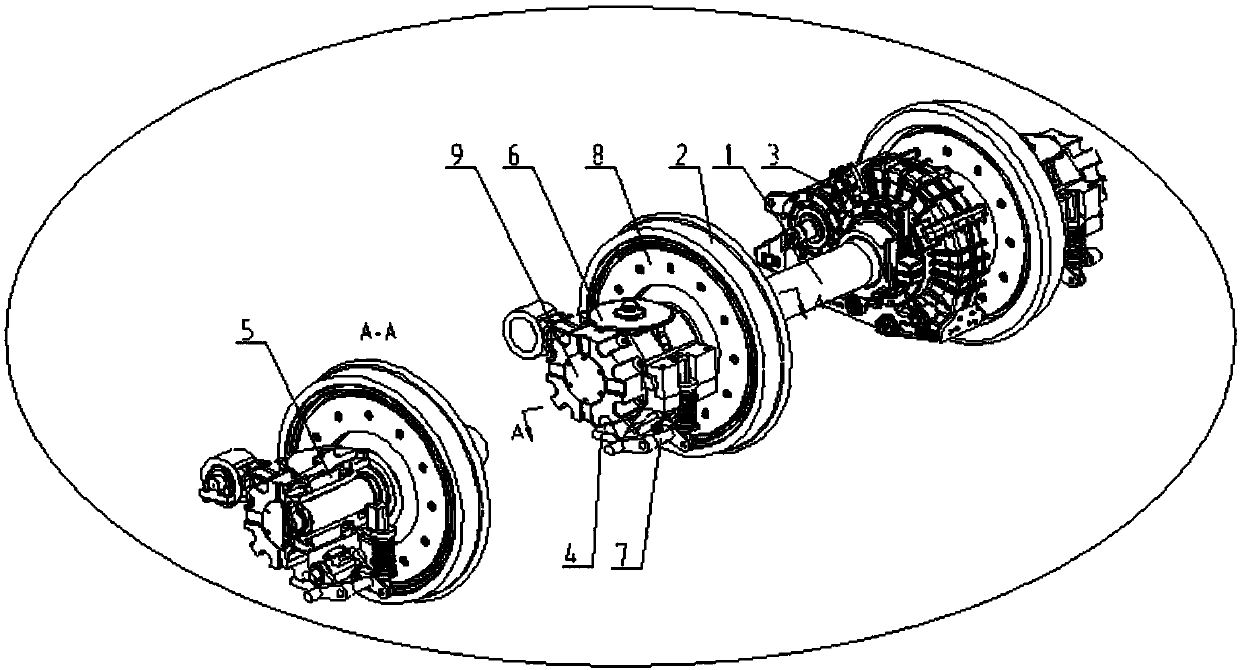

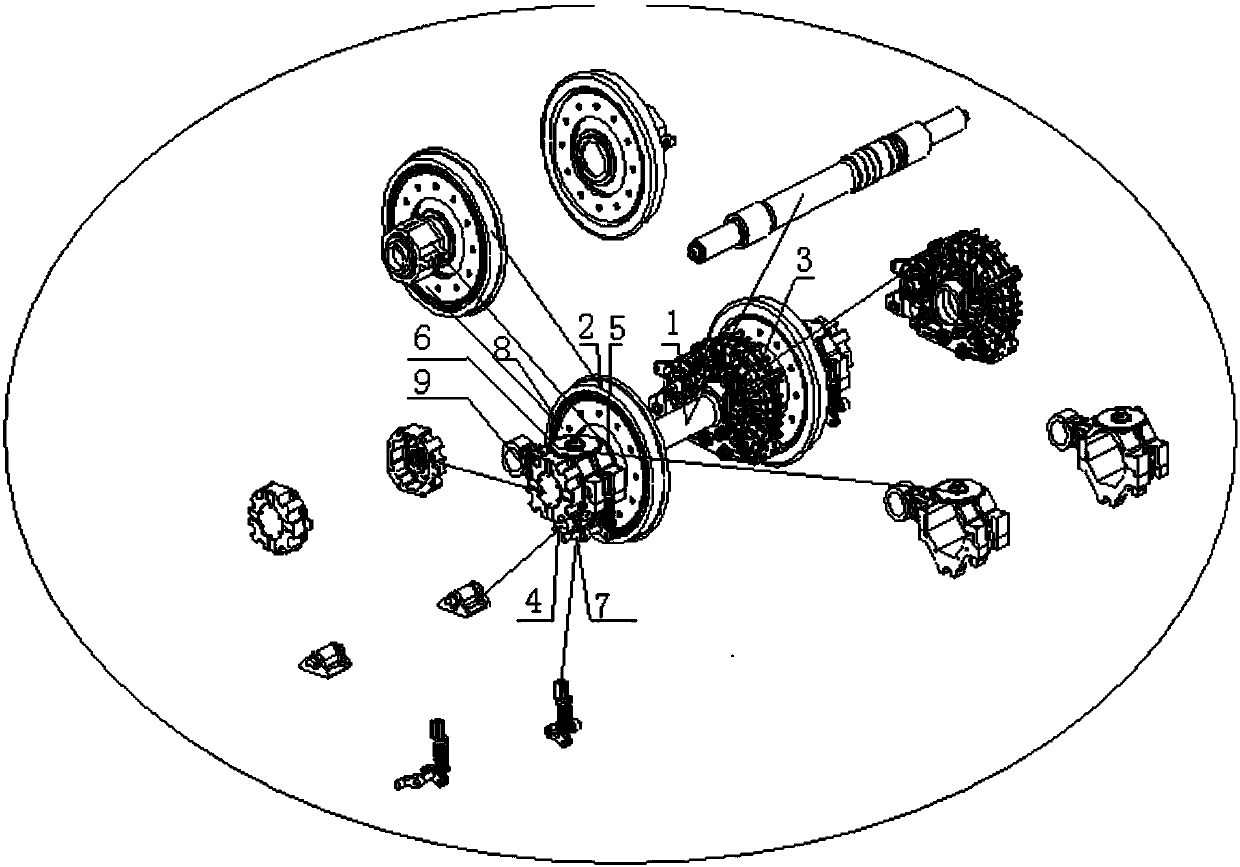

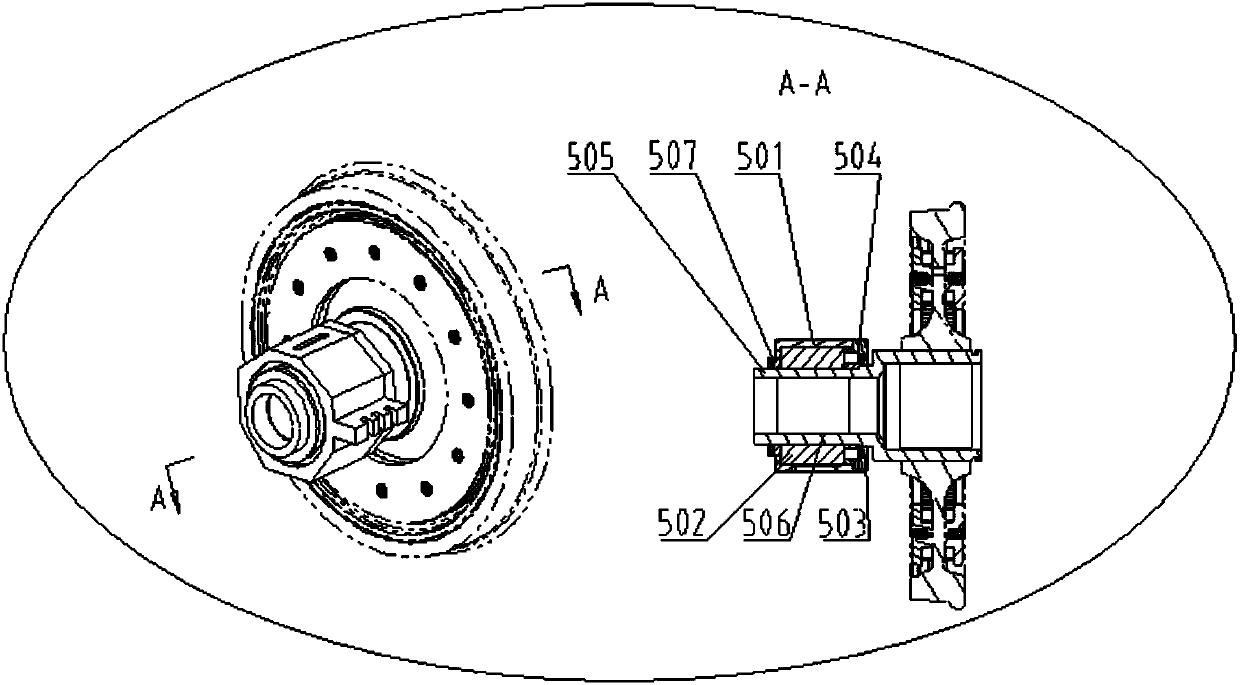

[0026] refer to figure 1 , figure 2 The specific embodiment of the present invention includes a power axle 1, a wheel 2, a gearbox 3, a bearing seat 4, a sliding mechanism 5, an axle box assembly 6, a locking mechanism 7, a wheel-mounted brake disc 8, and an axial positioning mechanism 9, The wheel-mounted brake disc 8 is connected to the wheel 2 through a fastener, and the sliding mechanism 5 is installed on the power axle 1, and is axially fixed by a locking mechanism 7 . The wheel 2 and the axle box 6 are respectively set and fixed on the sliding mechanism 5. The sliding mechanism 5 is used to drive the wheel 2 to slide on the power axle 1 when changing the track, and cooperate with the power axle to transmit torque during operation to drive the wheel to rotate. The locking mechanism 7 is set between the sliding mechanism 5 and the axle box assembly 6. When the gauge is about to change, the locking mechanism 7 unlocks the sliding mechanism, and the sliding mechanism break...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com