Cable clamp rail

A technology of cable clips and cable clips, applied in the direction of electrical components, etc., can solve the problem of small application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

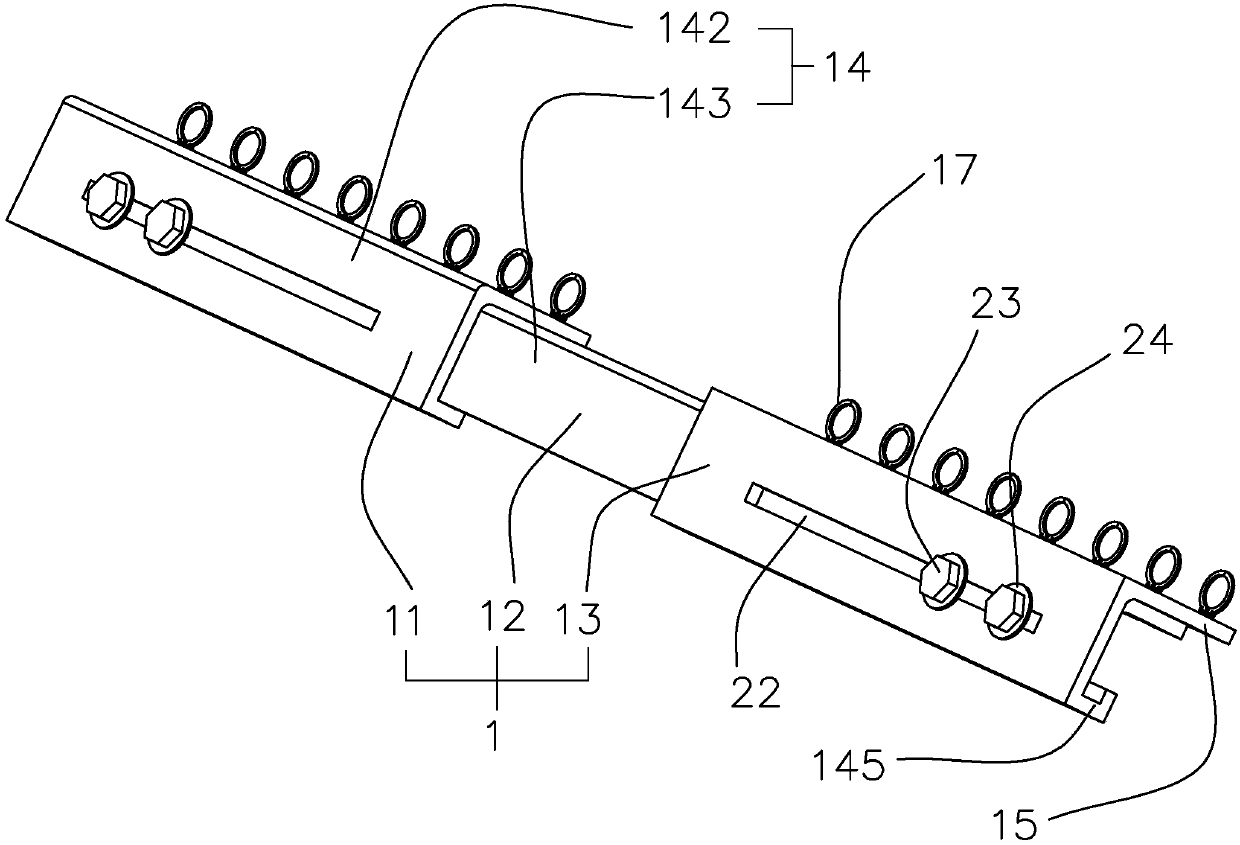

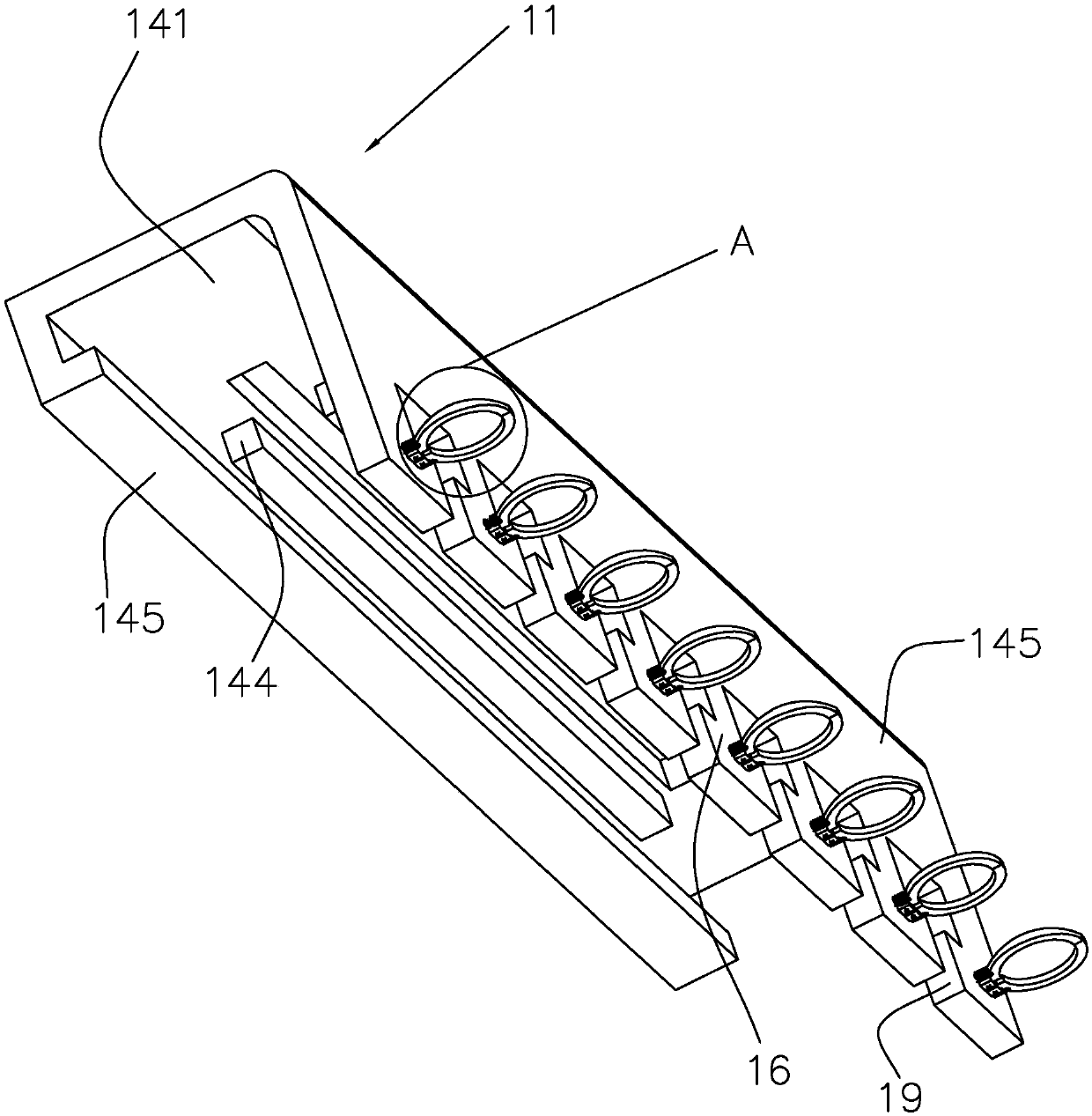

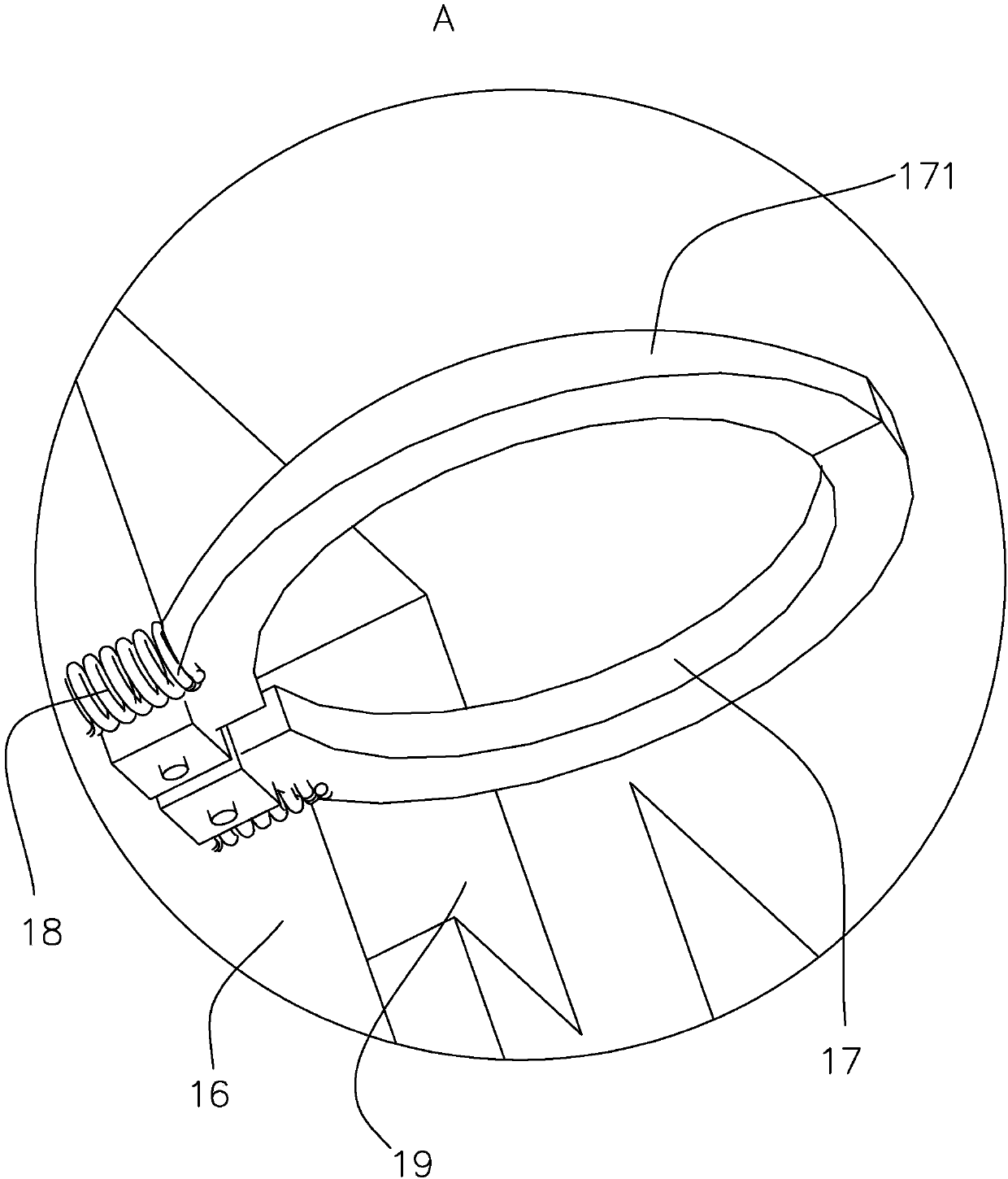

[0033] A cable clamp rail such as figure 1 and figure 2 , including a cable clip 1, a plurality of cable grooves 19 are opened on the cable clip 1, and the cable clip 1 includes a component 11, a component 2 12 and a component 3 13, and the component 11 and the component 3 13 are respectively slidably connected to the component two At both ends of 12, a locking device is provided between component one 11 and component two 12, and a locking device is also arranged between component three 13 and component two 12. The first component 11, the second component 12 and the third component 13 are all set in an "L" shape, and the first component 11, the second component 12 and the third component 13 all include a horizontally arranged connecting plate 14 and a vertically arranged wiring board 15, and the wiring The groove 19 is disposed on the wiring board 15 . The connecting plate 14 includes a fixed plate 142 and a moving plate 141, the fixed plate 142 is set on the second compone...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap