Up-down double-roller conveyor line structure

A conveyor line and double-drum technology, which is applied in the field of upper and lower double-drum conveyor line structures, can solve problems such as not being able to meet customers' high-efficiency needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

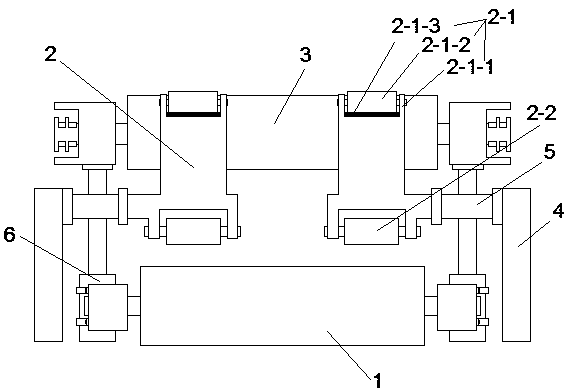

[0017] like figure 1 As shown, the embodiment of the present invention includes an unpowered roller track 1, a lifting wheel frame 2, and a driving roller track 3 arranged sequentially from bottom to top, wherein the unpowered roller track 1 can adopt an ordinary roller structure, and the driving roller track 3 passes through The motor drives the belt to rotate to actively drive and transport objects. The drive roller track 3 is connected above the unpowered roller track 1 through a hydraulic telescopic cylinder 6. The lifting wheel frame 2 is set between the unpowered roller track 1 and the drive roller track 3. , the upper end of the lifting wheel frame 2 is provided with a brake bracket 2-1, and when the transmission drum track 3 descends, the brake bracket 2-1 is exposed from the gap between the cylinders of the transmission drum track 3, thereby the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com