Ultrasonic suspension surrounding paint-spraying complete machine

An ultrasonic and complete machine technology, applied in spray booths, spray devices, etc., can solve problems such as ideal spraying confusion and inability to stick hands, and achieve the effects of efficient completion of operations, convenient automatic rotation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

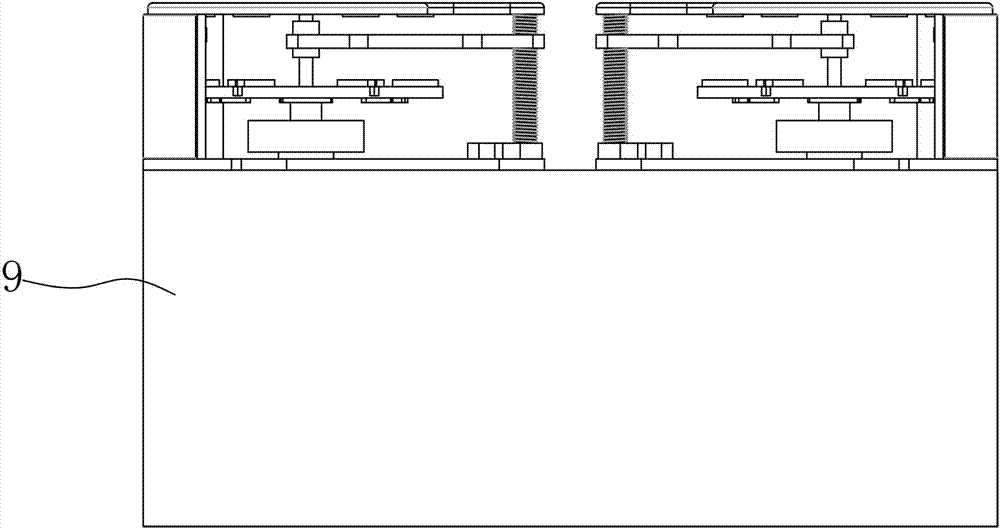

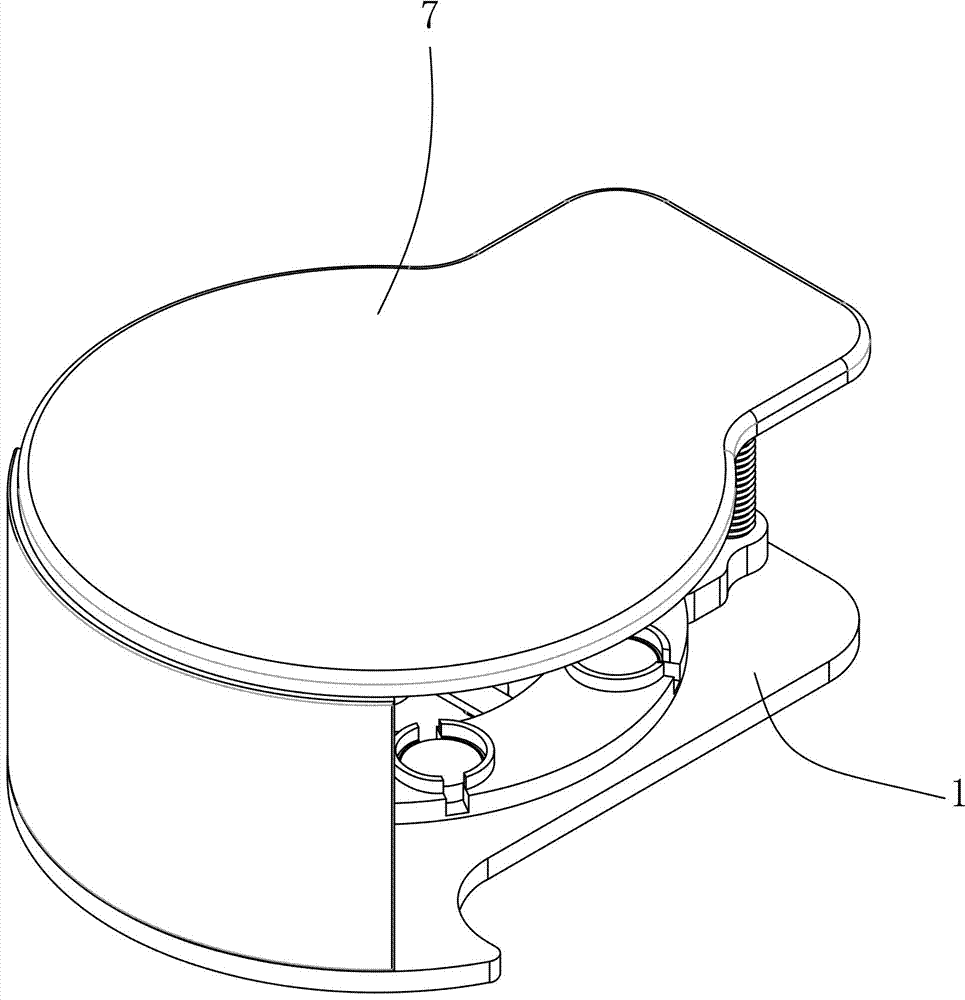

[0021] Such as Figure 1 to Figure 5 As shown, an ultrasonic suspension surround painting complete machine described in this embodiment includes a bottom frame 9, and at least one set of painting devices are arranged on the top surface of the bottom frame;

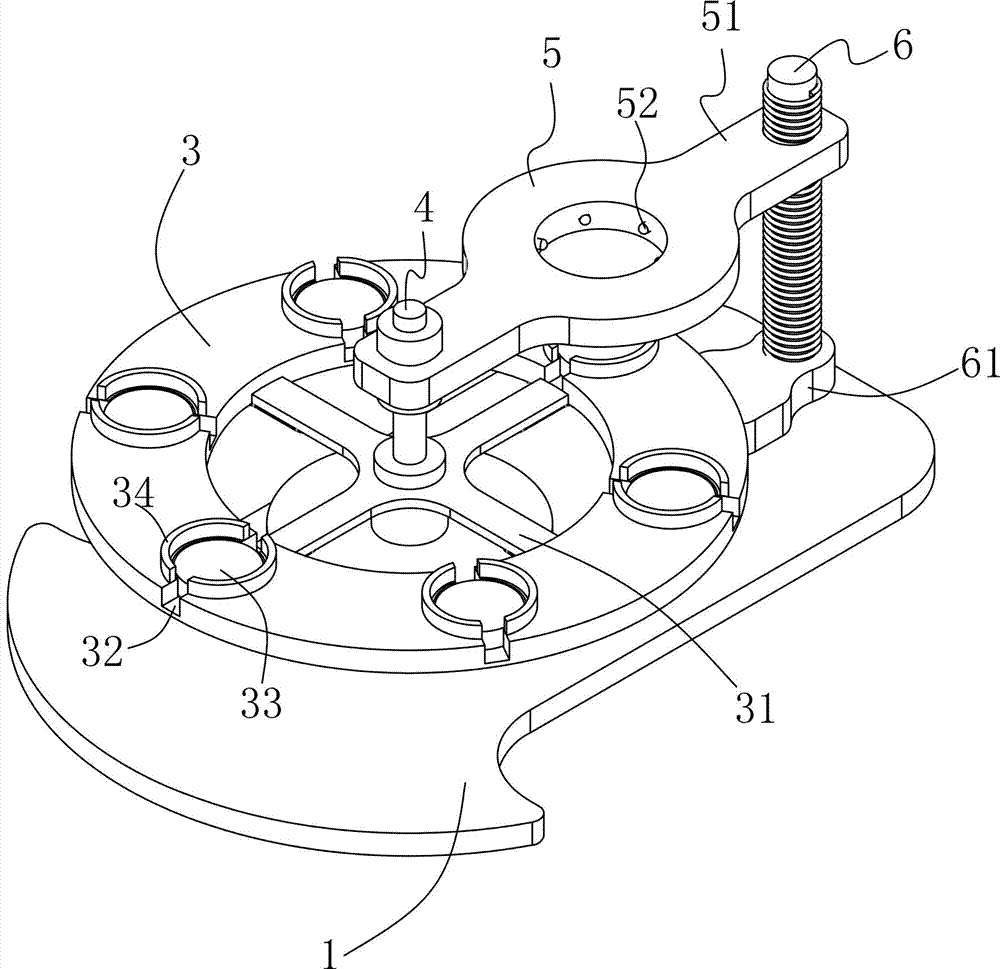

[0022] Described each painting device comprises base plate 1, and described base plate 1 is provided with first rotating electrical machine 2, and the power output end of first rotating electrical machine 2 is connected with rotating frame 31; Also comprises a rotating disc ring 3, rotating disc The ring 3 and the rotating frame 31 are concentrically arranged and fixed together; the top surface of the rotating disk ring 3 is provided with a plurality of placing grooves 32 arranged around the center of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com